Gammon Gauge™

Direct Reading Differential Pressure Gauge

Why settle for less when you can have the tried and true original ?

Unique Features

Common Features of all Models of the Gammon Gauge™

Calibration Testing

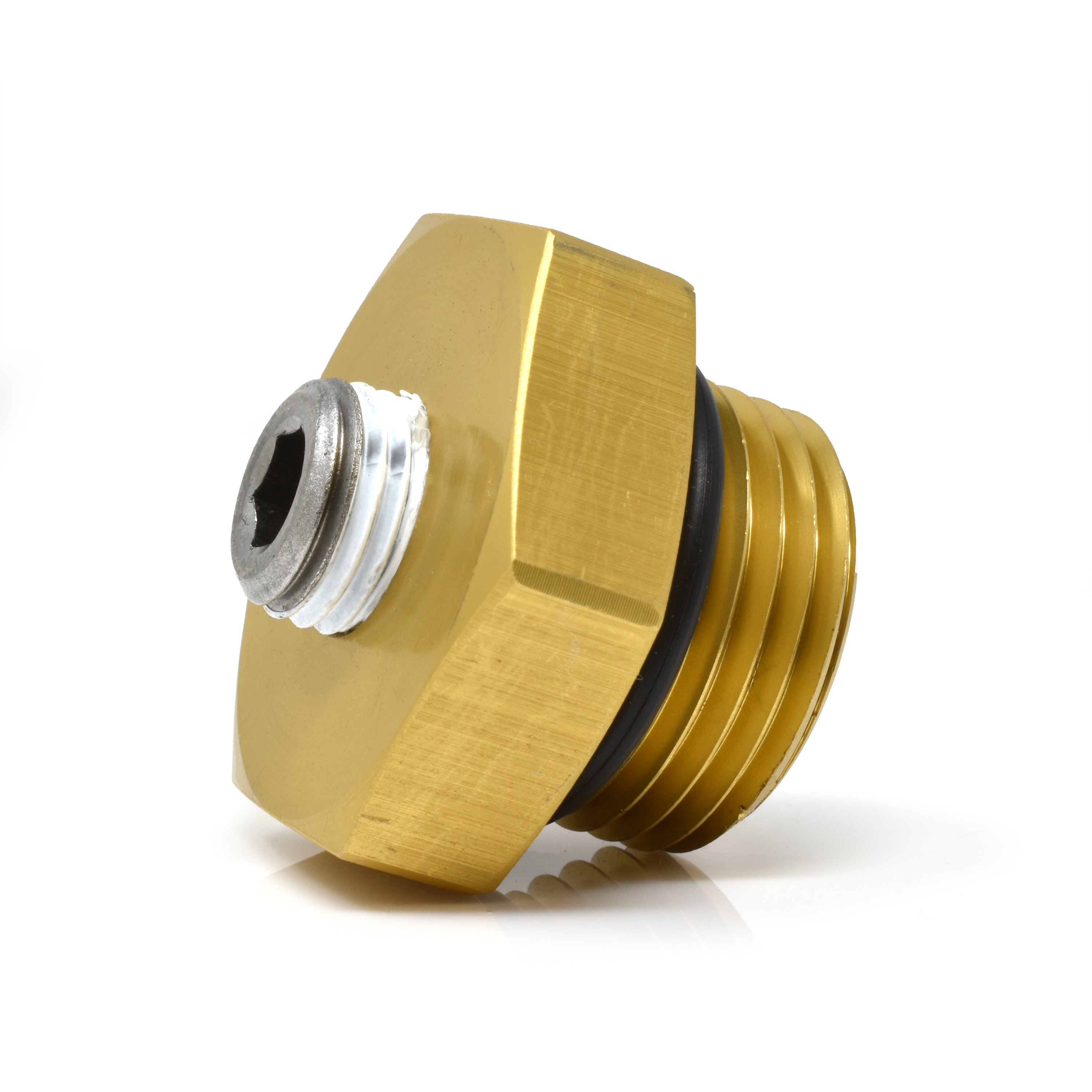

To meet API-1581, you should have a 3-way valve. Our 3-way valve meets this requirement and is used to check calibration as well as to check free movement of the piston.

- Establish flow in the system. The gauge should indicate a pressure drop.

- Push the test button. The piston should travel to the bottom of the scale.

- Release the button and stop flow in the system. The piston should return to zero.

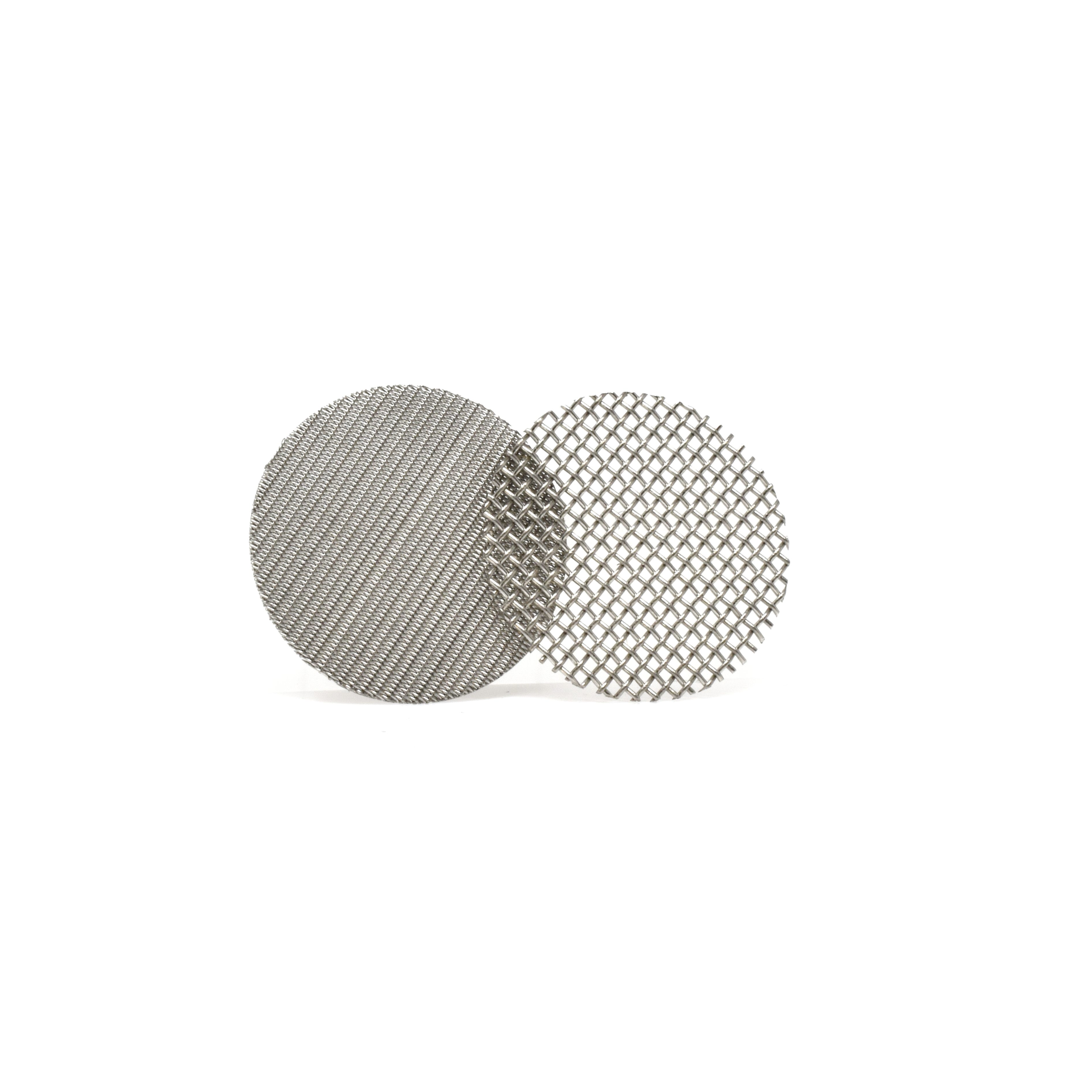

If the piston returns to zero, you have not only calibrated the gauge, you have checked it for free moment across its entire range. If the piston moves slowly, the filter (located in the top of the gauge) may be clogged and need replacement. This calibration technique is accepted by all major oil companies, all major airlines, and military services worldwide. Gammon Gauges™ have been in service in virtually every major airport in the world for as long as 30 years and we have never heard of or seen a single gauge go out of calibration. Occasionally a piston will stick after many years in service, but hand cleaning with “Scotch Brite” plastic abrasive will make it as good as new (Note: Do not clean with sandpaper or steel wool). Replace the o-rings and reassemble.

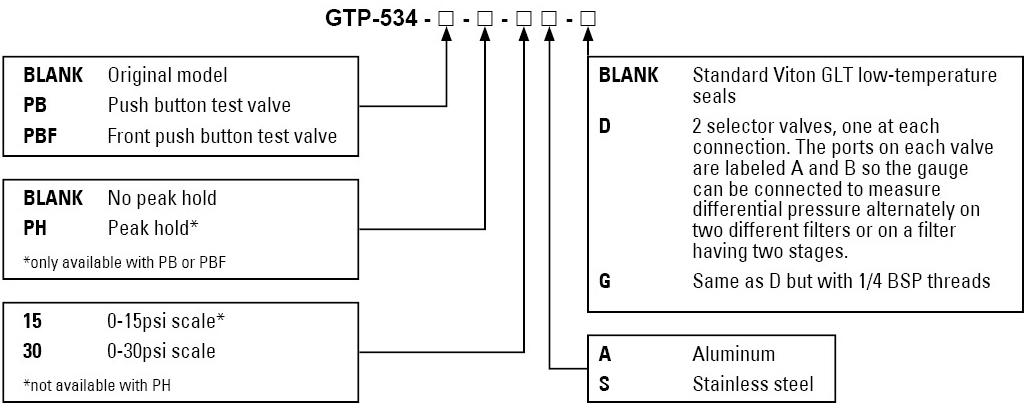

How to Order

Accessories & Replacement Parts

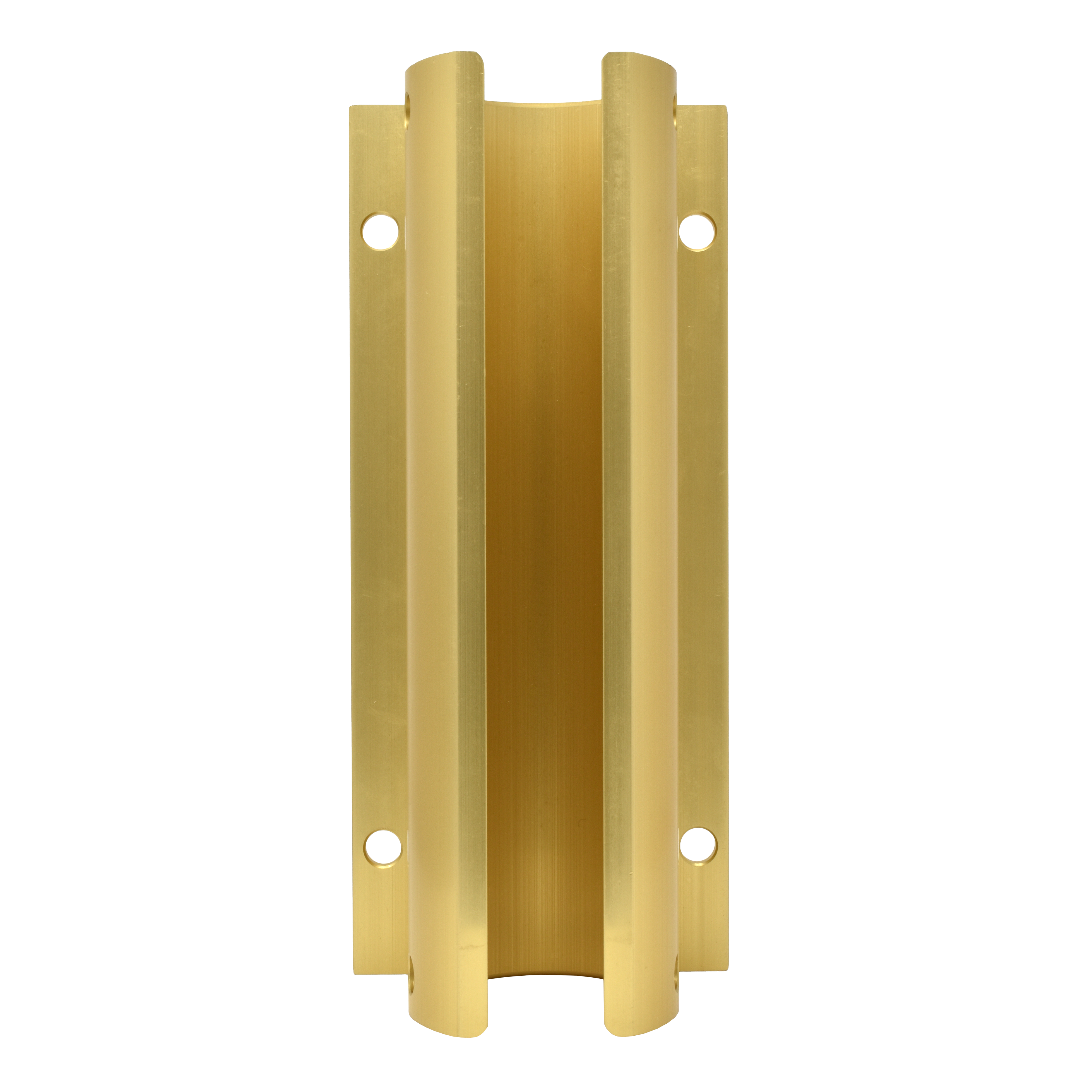

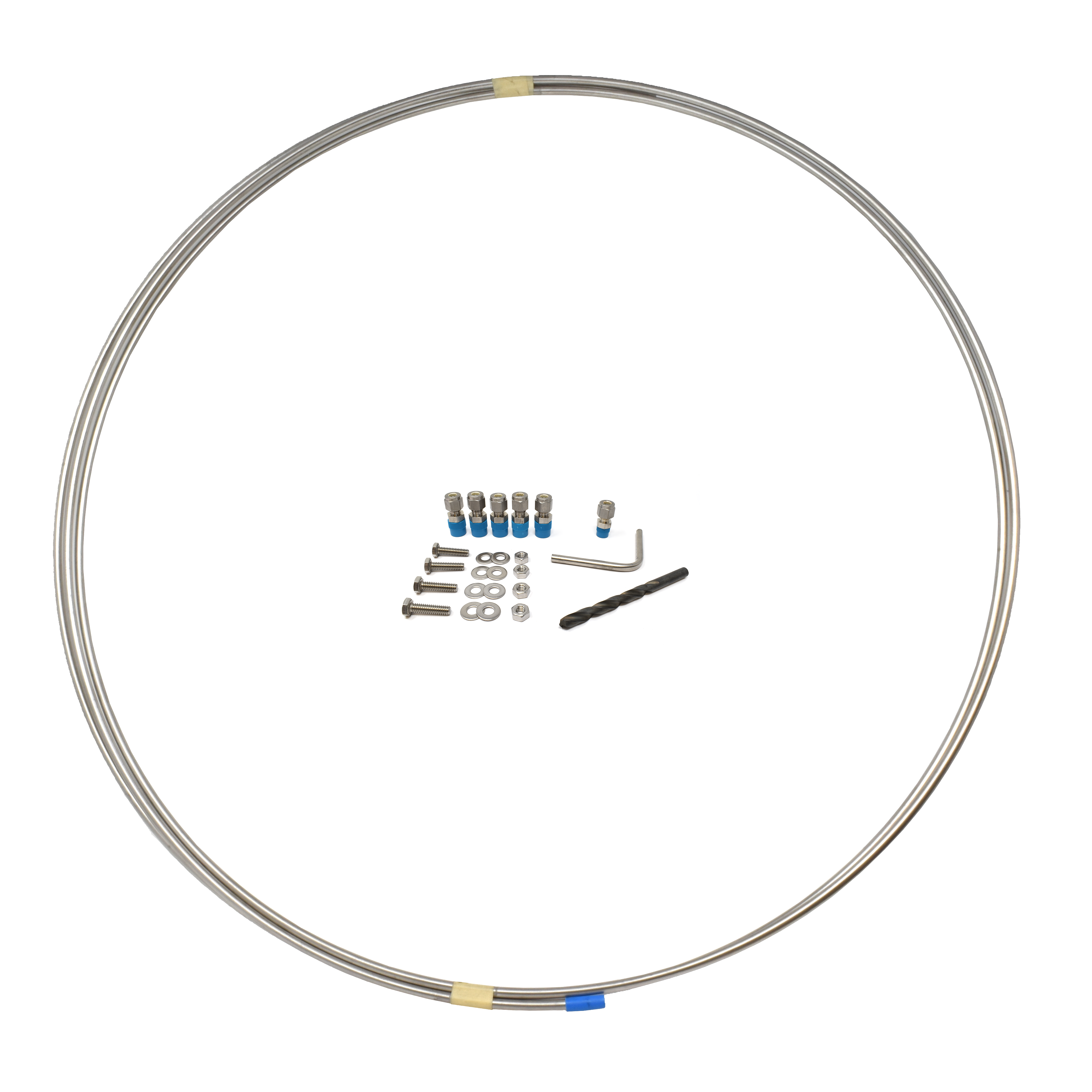

Retrofit Kits for GTP-534

An existing Gammon Gauge™ can be converted to have the Peak-Hold and the Push Button Test Valve by replacing the lower flange of the gauge. On Gammon Gauges™ without test buttons, a GTP-2305V 3-way ball valve can be installed.

Gammon Gauge™ Control Systems

Protect Against Filter Element Bursting

Add a Differential Pressure Switch to the Gammon Gauge™

Sound Alarm – Stop Flow – Turn on Second Filter

Normally Open or Normally Closed, Fail Safe

If differential pressure suddenly increases or a facility is operated without personnel monitoring the differential pressure, filter element failure can occur. This new switch is unique. It adds differential pressure control at a low cost using a non-powered proximity switch. This simple double-sealed switch is ideal for use in PLC (miniature computer) and relay controlled systems. The connection box is rated NEMA 4X.

Control operations are also available if you don’t plan to use an external control. We have weather-tight and explosion-proof versions.

We strongly recommend a 3-way test valve for properly testing the Gammon Gauge™ and Proximity Switch and/or system.

Any Gammon Gauge™ can be converted to include the new proximity switch.

Note: To meet IATA JIG Bulletin 58, order one of the “KS” options for key switch reset and test functions. The ATA-103 does not require this. For vehicle mounting, we recommend the weather-tight housing.

Notes:

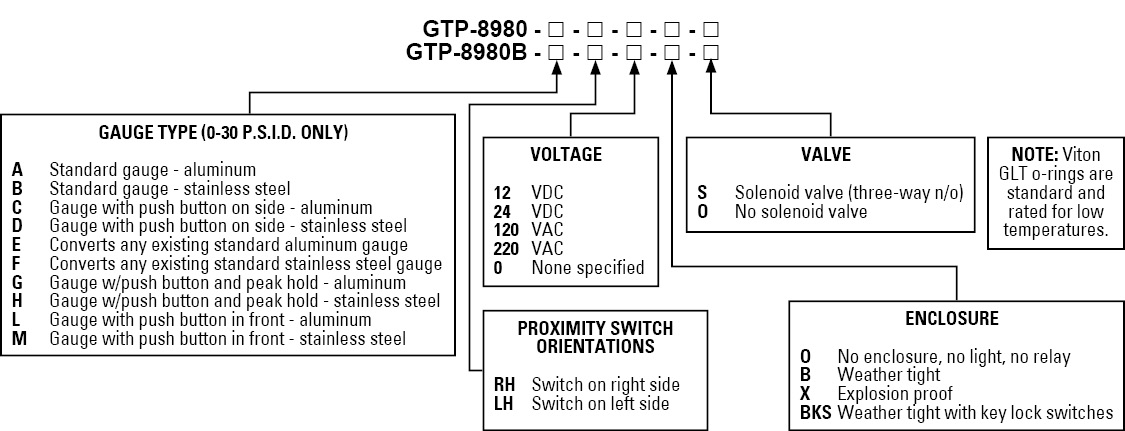

How to Order

Examples

GTP-8980B-C-RH-12-B-0 is a differential pressure gauge with a normally closed switch as follows: push button aluminum gauge, 30 psi scale, switch on right side, 12 VDC, enclosure is weather tight which includes light and push to test feature, no solenoid valve, and low temperature o-rings.

GTP-8980B-C-RH-12-BKS-0 is the same as above except the enclosure has 2 key lock switches for test and reset per IATA JIG Bulletin 58.