Closed Circuit Testing with the Meter Monitor

No need for a measuring bucket. No need to dispose of fuel.

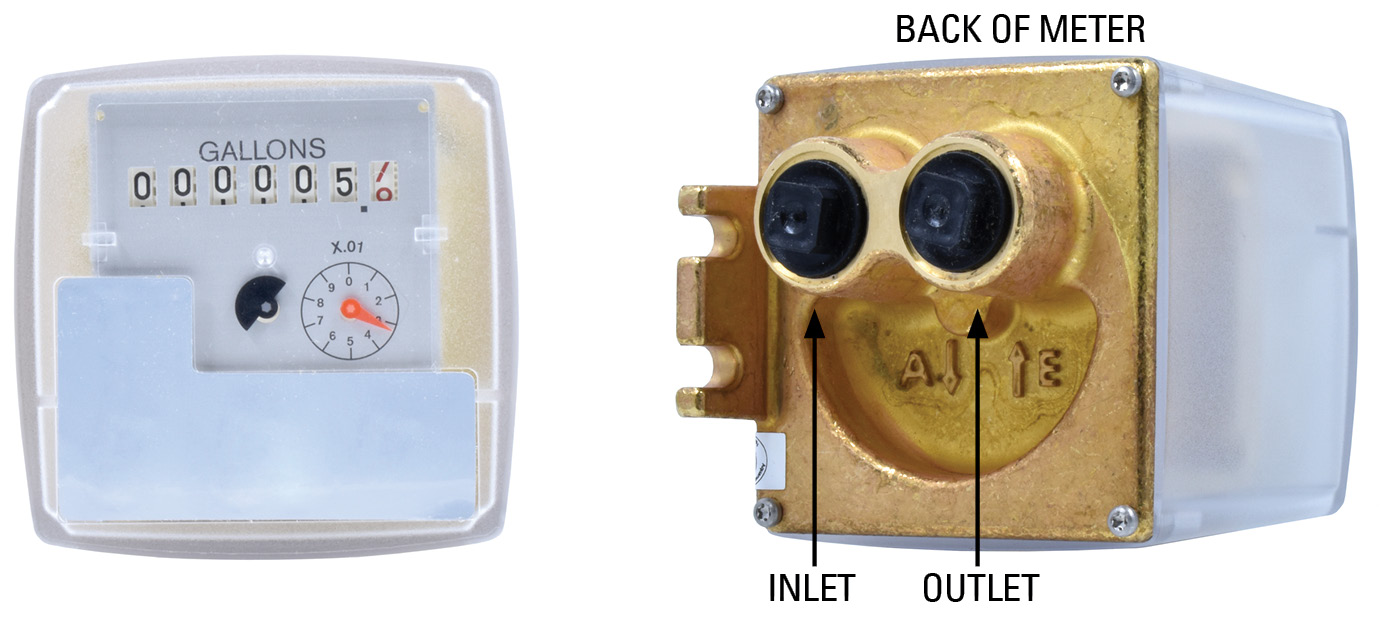

When performing filter membrane tests, the difficult part of the task is disposing of the test fuel. The Meter Monitor solves that problem completely. The flush and the test fuel are both returned to the fuel system and are never exposed to air, rain, or other contaminant sources. No buckets, funnels, or fuel spills. The Meter Monitor has two 1/8” NPT connections (connections are 1/4” NPT, inlet and outlet; we install bushings to 1/8” NPT).

Available with gallon or liter calibration.

NOTE: The standard model is made for petroleum service (jet fuel). An optional version for metering anti-icing additive (diEGME) is also available with specially-designed seals.

Testing Procedure

NOTE: The return line may also be connected anywhere that the pressure is reasonably less than the sampling pressure – to the storage tank, the truck tank, even a venturi throat. For operating at pressures over 125 psi, contact the factory or your distributor.

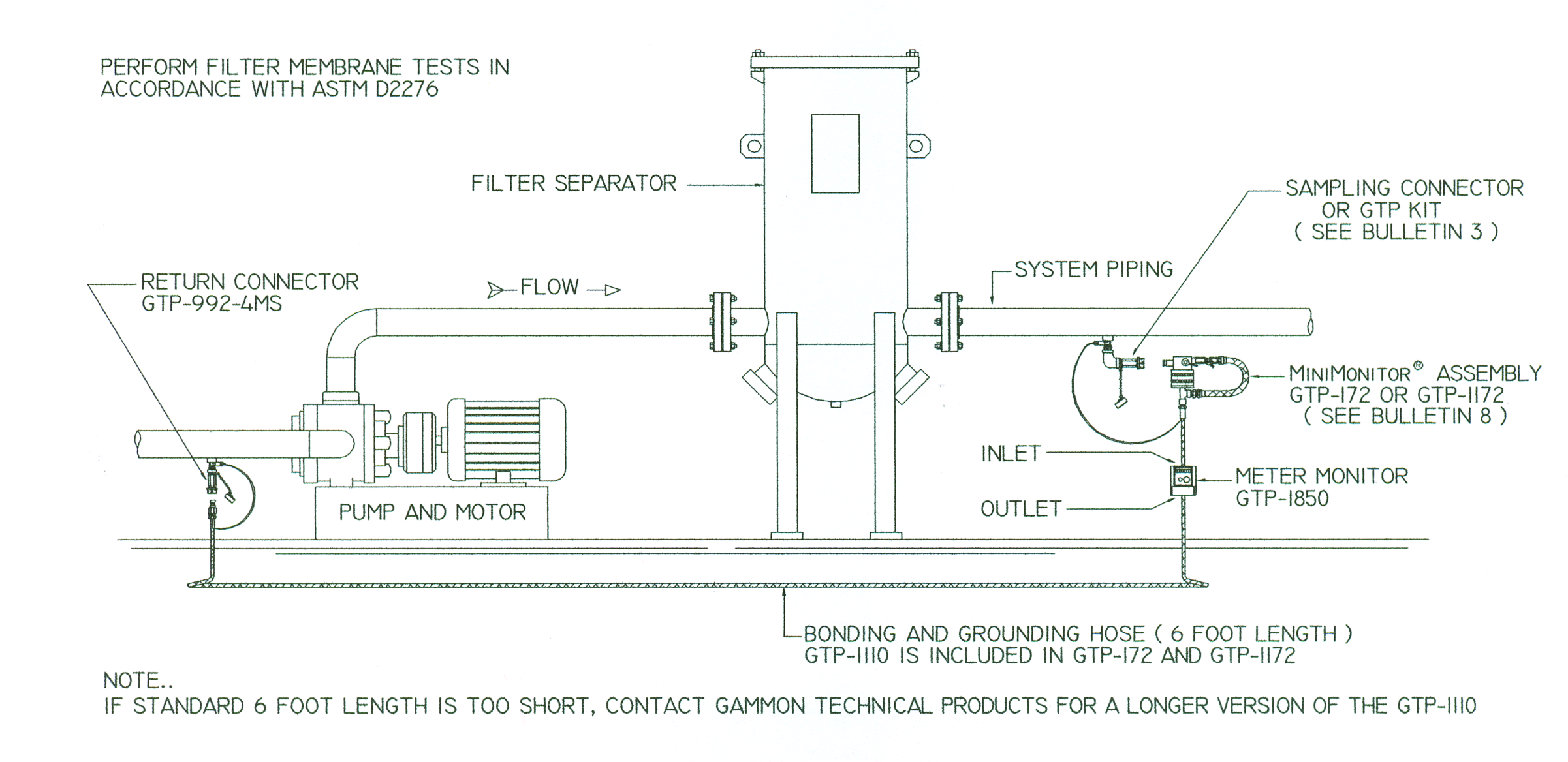

- Install a return connector at the inlet of the system pump (GTP-992-4MS).

- Using a MiniMonitor® housing that you may already own, insert a plastic monitor (see Bulletin 8).

- Install the Meter Monitor between the MiniMonitor® assembly and grounding hose (GTP-1110) which comes with the MiniMonitor® kit.

- Turn the MiniMonitor® valve to the stop position.

- Start flow in fuel system and read the meter position, for example 000089.23

- Connect the MiniMonitor® inlet to the sampling connector and connect the outlet of the hose to the return connector.

- NOTE: The six numerals to the left of the decimal point read whole gallons. The right hand window reads tenths (0.1) of gallons. The dial reads hundredths (0.01) and can be estimated to 0.002. This is a non-reset type meter.

- Turn the MiniMonitor® valve to the flush position. If you plan to flush one gallon, stop the flushing after one gallon. In this example, stop at a reading of 000090.23.

- Turn the MiniMonitor® valve to the test position. Then turn the valve off when the correct number of test gallons has passed. Disconnect the return connection, then the sample connection.