Over 1,000 in service worldwide

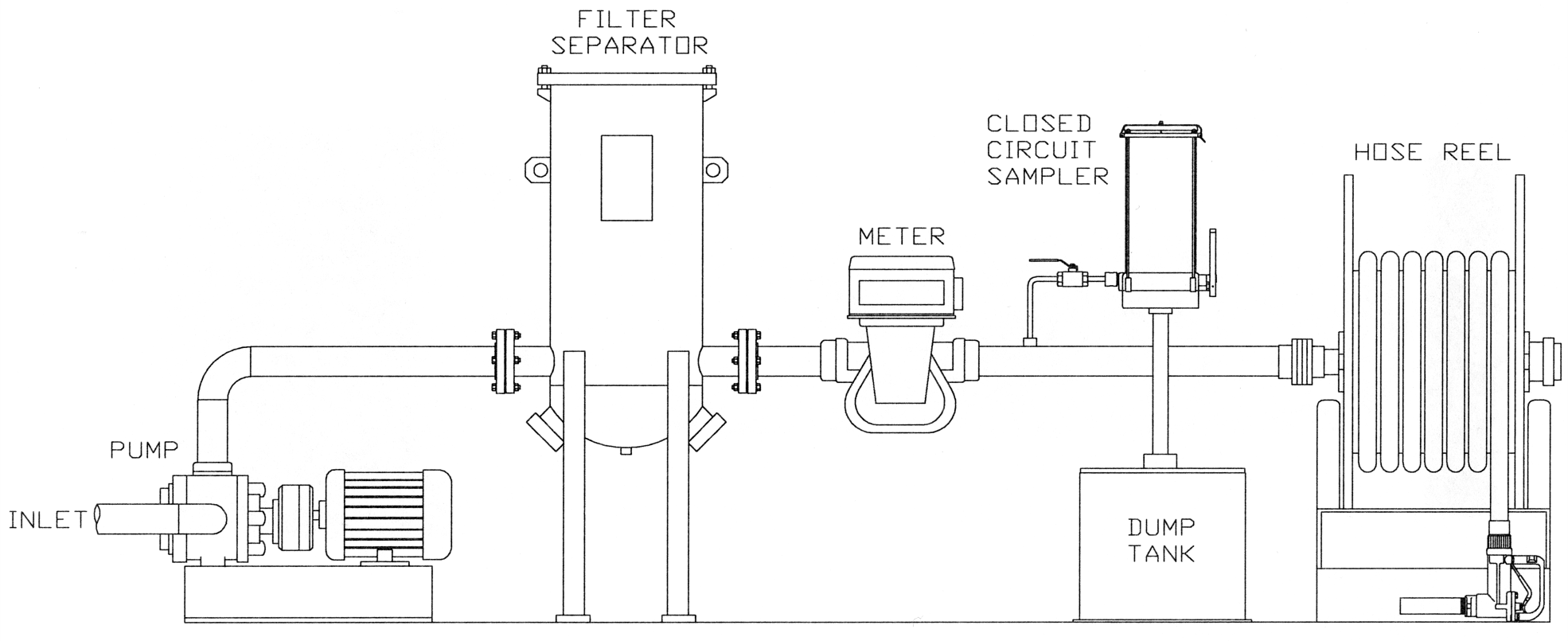

When drawing a visual sample of fuel from the filter separator sump, you learn immediately whether or not there was any water in the fuel supply. If the fuel is hazy, the filter separator is not functioning properly. If it is clear and bright but liquid water is found in the closed circuit sampler, you can reason that the filter separator is coalescing the water, but you surely will want to check the source of the supply. Dirt particles indicate that the coalescers are not filtering properly.

Installation

In most sampler installations, the sample is taken directly from the flow stream after the filter separator or monitor. A light located behind the sampler is very useful at night. The condition of the fuel just before it enters the aircraft provides the operator with immediate information. Alternatively, some operations may prefer to check a sample of fuel from the filter separator sump to learn immediately if any water or particulate contamination was in the fuel supply.

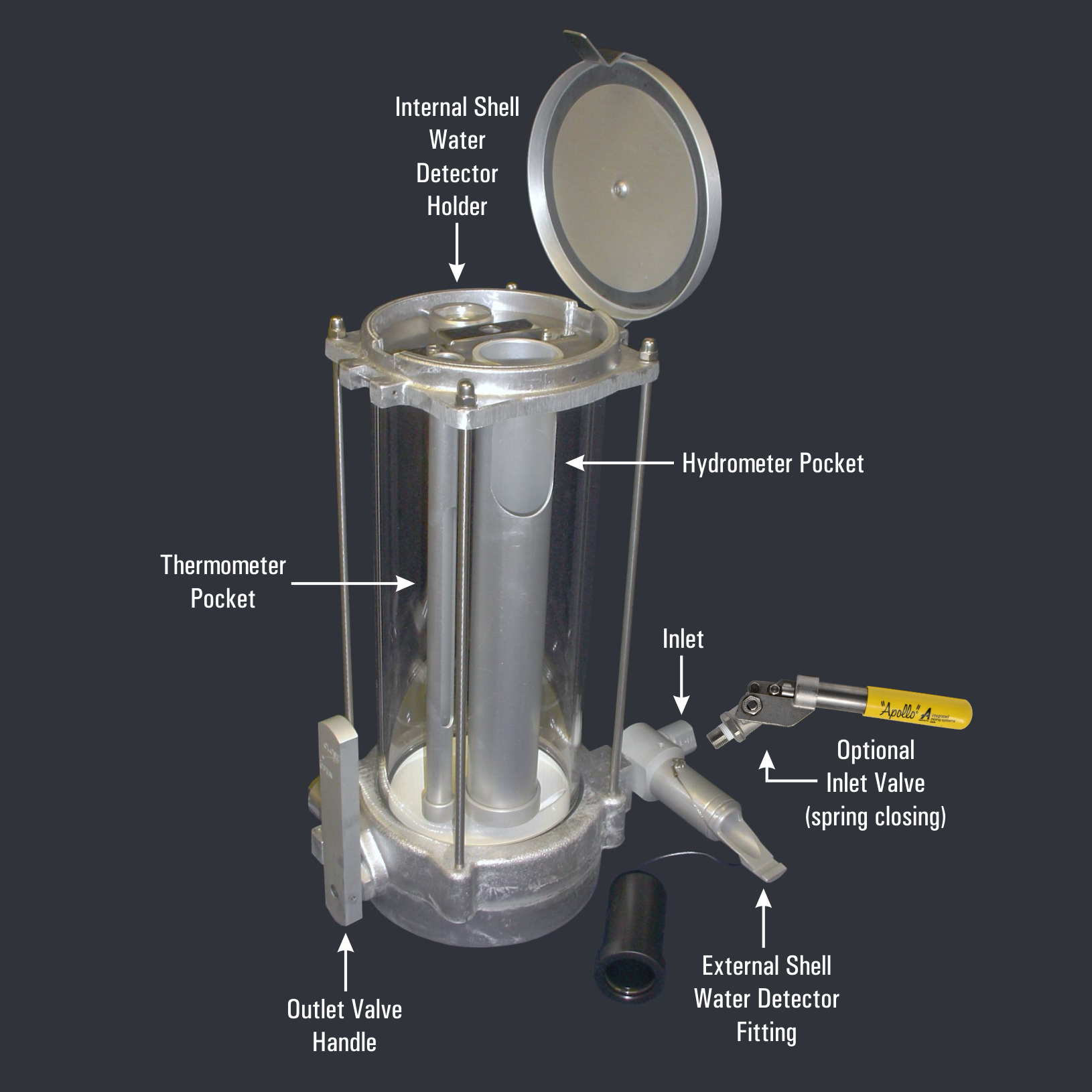

Fuel enters the sampler tangentially at the bottom, creating a clockwise swirl to force particles and water to the center of the coned-down, white epoxy chamber bottom. Any contaminants are then easily seen. After inspection or testing, simply open the outlet valve to release the contents to the dump or slop tank.but the range has been reduced so they will fit in the Aljac sampler.

Hydrometers and Thermometers for Closed Circuit Samplers

Standard length ASTM hydrometers and thermometers are too long to fit the holders if it is desire to leave these instruments in place with the lid closed. For customers who want to leave them in place, we offer special short models as follows.

These hydrometers have shorter scales than are required for standard ASTM models. For example, in the metric models, the graduations are 2.14 mm apart for 1 kg instead of 2.59 mm for standard hydrometers. These thermometers have the same graduation spacings as for standard ASTM thermometers such as 12°C and 12°F but the range has been reduced so they will fit in the Aljac sampler.

See Bulletin 61 for product information.

Specifications

| Body: | Aluminum |

| Cylinder: | Borosilicate glass |

| Seals: | Viton A |

| Outlet Ball Valve: | Stainless steel |

| Temperature: | 50°C maximum |

| Pressure Rating: | None, this is a container only |

| Capacity: | 4 liters (1 US gallon) standard 20 liters (5.25 US gallons) optional |

Installation Specifications

| Inlet: | 3/8″ NPT |

| Outlet: | 1″ NPT (3/8″ BSP adapter included) |

| Mounting: | 2 3/8″ – 16 bolts |

How to Order

| Model No. | Description |

|---|---|

| JM-3001 | Basic model – includes outlet drain valve only |

| JM-3001-2 | Same as JM-3001 but includes internal fitting for Velcon Hydro-Kit test |

| JM-3001-3 | Same as JM-3001 but includes internal fitting for Shell water detector syringe |

| JM-3001-4 | Same as JM-3001-2 but includes thermometer and hydrometer holders |

| JM-3001-5 | Same as JM-3001-3 but includes thermometer and hydrometer holders |

| JM-3001-16 | Same as JM-3001 but includes thermometer and hydrometer holders |

| JM-3170 | Adds external Shell water detector fitting. Not available with JM-3204. |

| JM-3204 | Adds external Velcon Hydro-Kit fitting. Not available with JM-3170. |

| JM-3175 | Adds 3/8″ spring closing fill valve at inlet to any model number starting with JM-3001 |

NOTE: The above listed options are also available to retrofit existing equipment. Please call for details.