Fueling Adapter Wear Gauge, GTP-8963

Leakage during refueling is often caused by excessive wear on the underside of the three lugs that are located on the outer edge of the fueling adapter. This wear reduces the sealing force between the nose seal of the refueling nozzle and the sealing face on the adapter.

There are two consequences of excessively worn refueling adapters:

- Leakage when the nozzle is attached.

- A major spill if the nozzle is accidentally removed from the adapter while the nozzle valve is still in the open position.

Wear that develops on the underside of the three lugs is the most common problem. It causes leakage because it reduces the force on the seal between the nozzle and adapter. Our GTP-8963 wear gauge quickly determines whether the lugs are excessively worn. Each lug should be checked. If any of the three are overly worn, the adapter must be replaced.

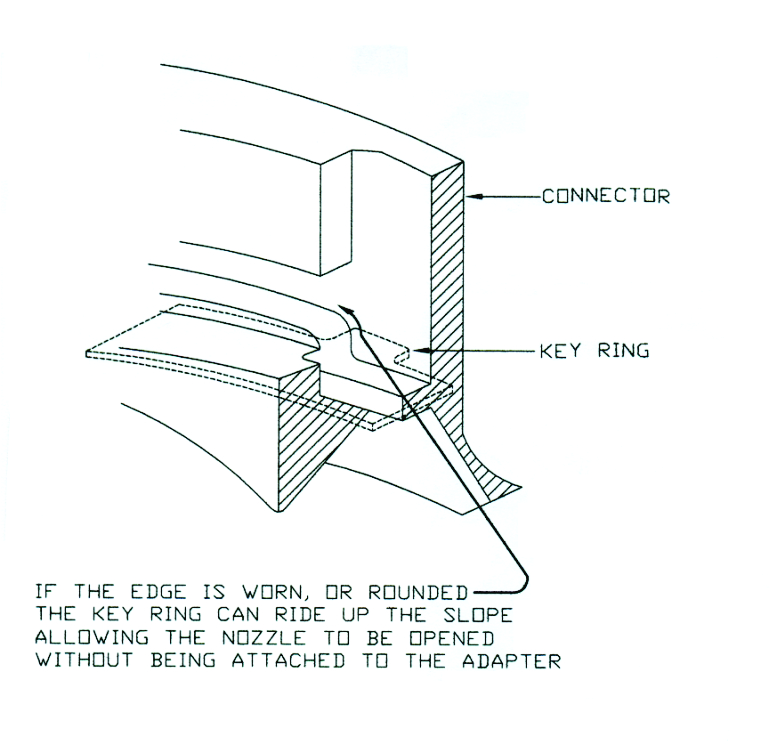

Failure of the interlock system can result in a major fuel spill because the nozzle could be disconnected from the fueling adapter before the nozzle valve has been closed. Excessive wear (0.062 inches) of the alignment slots of the adapter on the counter-clockwise side is the limit.

Lug width is important because excessive wear can result in this type of fuel spill in the same way as described above for slot wear.

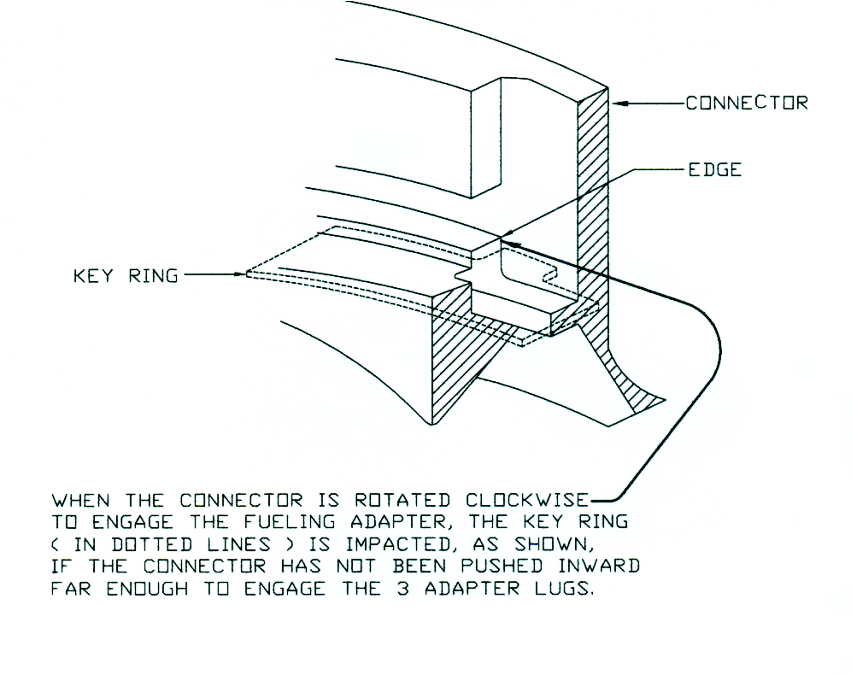

The most dangerous adapter condition is wear that can allow the nozzle to be removed before the valve is closed. On “3-pin type” nozzles, this wear occurs in the three slots, about ¼ inch (6.4 mm) wide, which are located between the lugs. When a nozzle is being attached to an adapter, the operator rotates the nozzle clockwise until it stops. This causes the nozzle pins to impact the clockwise side of each slot, causing wear. However, this wear is of no consequence. But when the nozzle is removed, the impact and wear occurs on the counter-clockwise side of the slots. This is the dangerous wear that our gauge measures.

To check for lug wear, set the gauge in the adapter and rotate it so that the gauging pin moves toward the lug. If the pin passes under the lug, there is excessive wear.

To check for slot wear, invert the gauge and set it on the adapter with the tongue in a slot. If the small pin completely enters the slot as shown, there is excessive wear.

To check for lug width wear, use the groove in the end of the gauge. If the lug enters the groove, there is excessive wear.

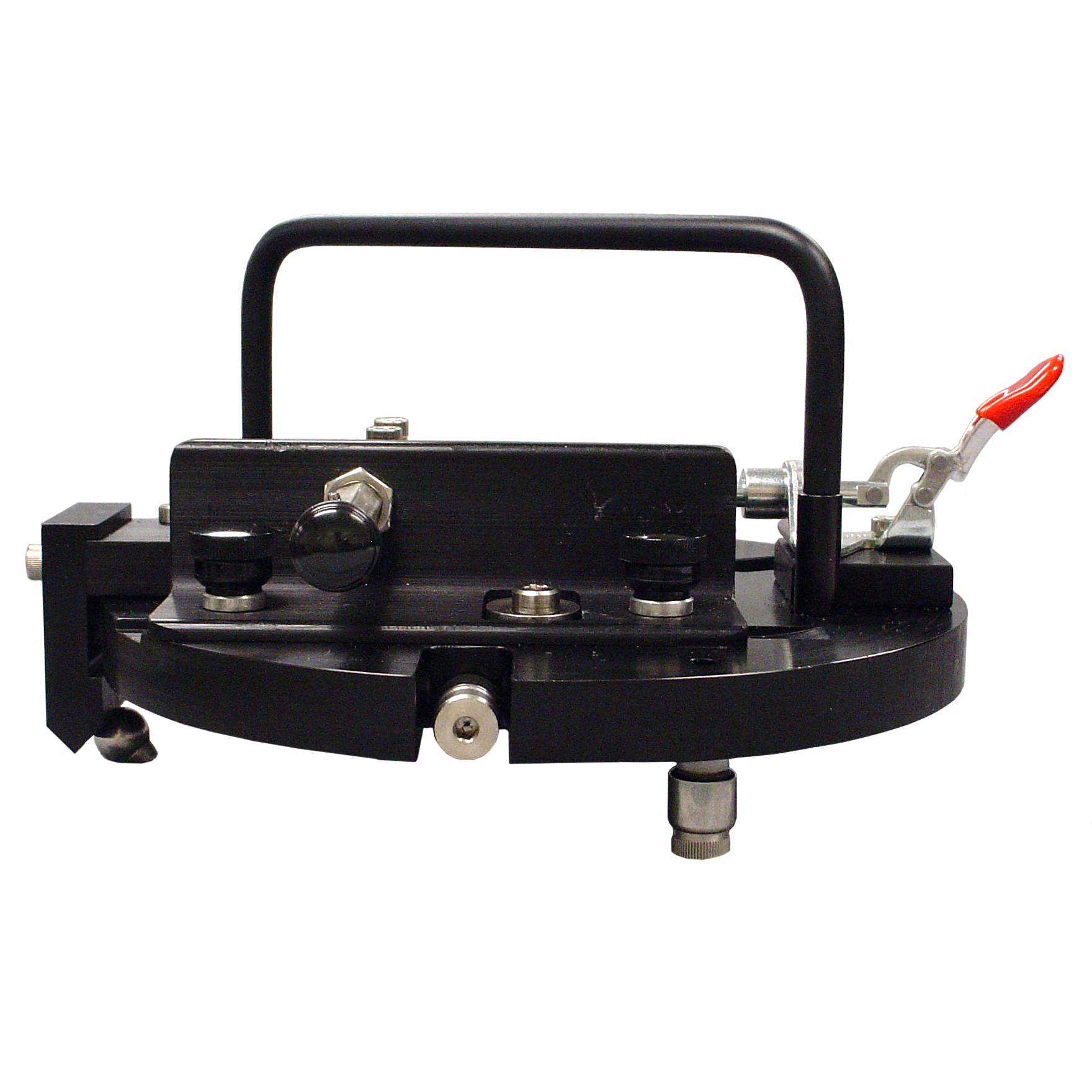

EI/API 4″ Adapter Wear Gauge, GTP-9410

For Hydrant System Pit Valves and Truck Loading Adapters EI/API 1584 and 1004

The GTP-9410 Wear Gauge is specially designed to detect wear on 4” EI/API adapters. Adapters wear in three areas, the top, the outside diameter and on the clamping surface. This simple instrument adds the wear on these surfaces into one measurement, and provides a simple indication that the adapter needs to be replaced.

This unique patented design makes checking for wear simple; it takes just seconds.

Included is a gauge block, factory calibrated to allow you to calibrate the gauge accurately before each use. Instructions and a Pelican case are included.

Included in GTP-9410:

Wear Gauge

Gauge Block

Carrying Case

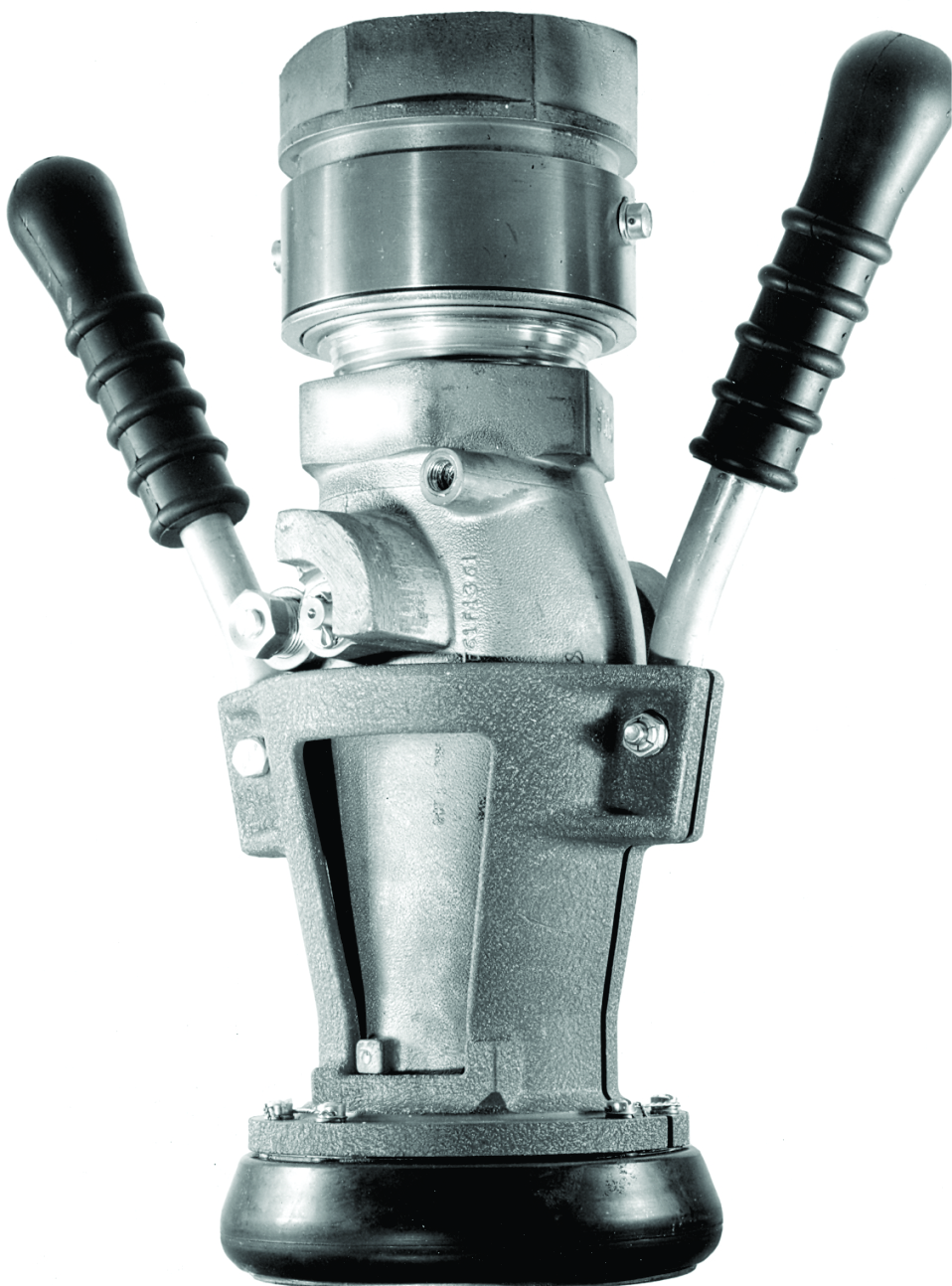

Nozzle Connector Wear Gauge, GTP-9192

For Whittaker Fueling Nozzles

The Gammon GTP-9192 is to be mounted on a firm surface such as a work bench or a wall. The technician then places the nozzle face against the gauge and attempts to rotate the nozzle as if making a connection to a 3-lug fueling adapter. If the nozzle will rotate, the wear is excessive. If the nozzle will not rotate, the wear is within suggested limits.

NOTE: When a connector is found to be worn, order the replacement 2662319. Whittaker also offers connectors that have stainless steel inserts at the 3 critical wear points. Order part number 2682020. In fact, Whittaker nozzles can be ordered with that special connector by specifying option J.