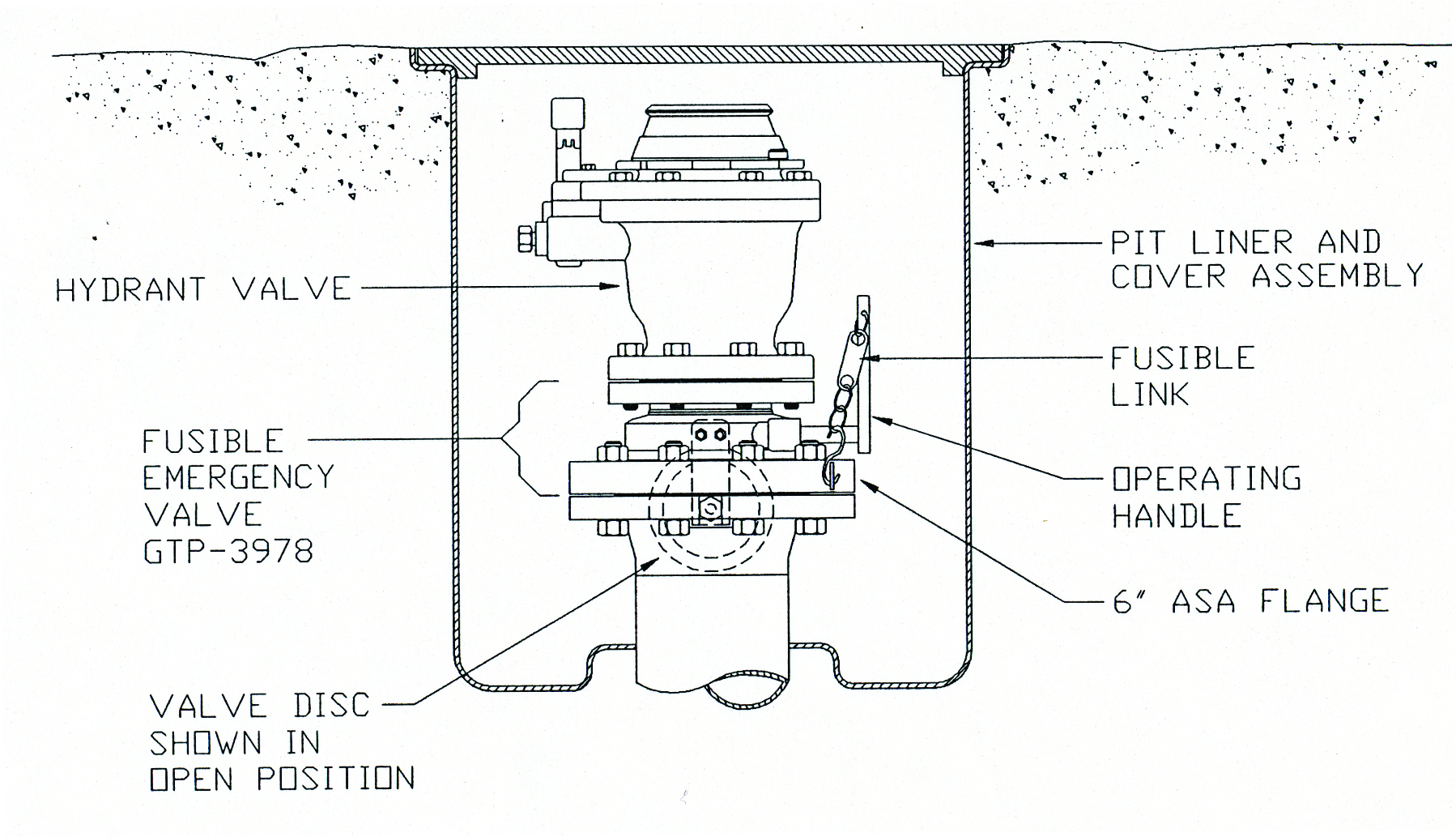

Refueling Hydrant Pit Shut-Off Valves

Overview

One thing is true of all hydrant pit control valves, and that is that they occasionally leak and/or need service. To stop the leak or service the valve without depressurizing the hydrant system, or a portion of it, a manual shut-off valve must be located between the hydrant pipe connection and the hydrant pit control valve.

Shut-off valves are sized either 4×4”, 6×4”, or 6×6” depending on the hydrant pipe size and the connection size of the hydrant pit control valve. The shut-off valve cannot be a “wafer” style valve; it must be flanged on the inlet and outlet. By using a flanged-type under-hydrant valve, the entire hydrant pit control valve can be removed, if necessary, and no leakage will occur.

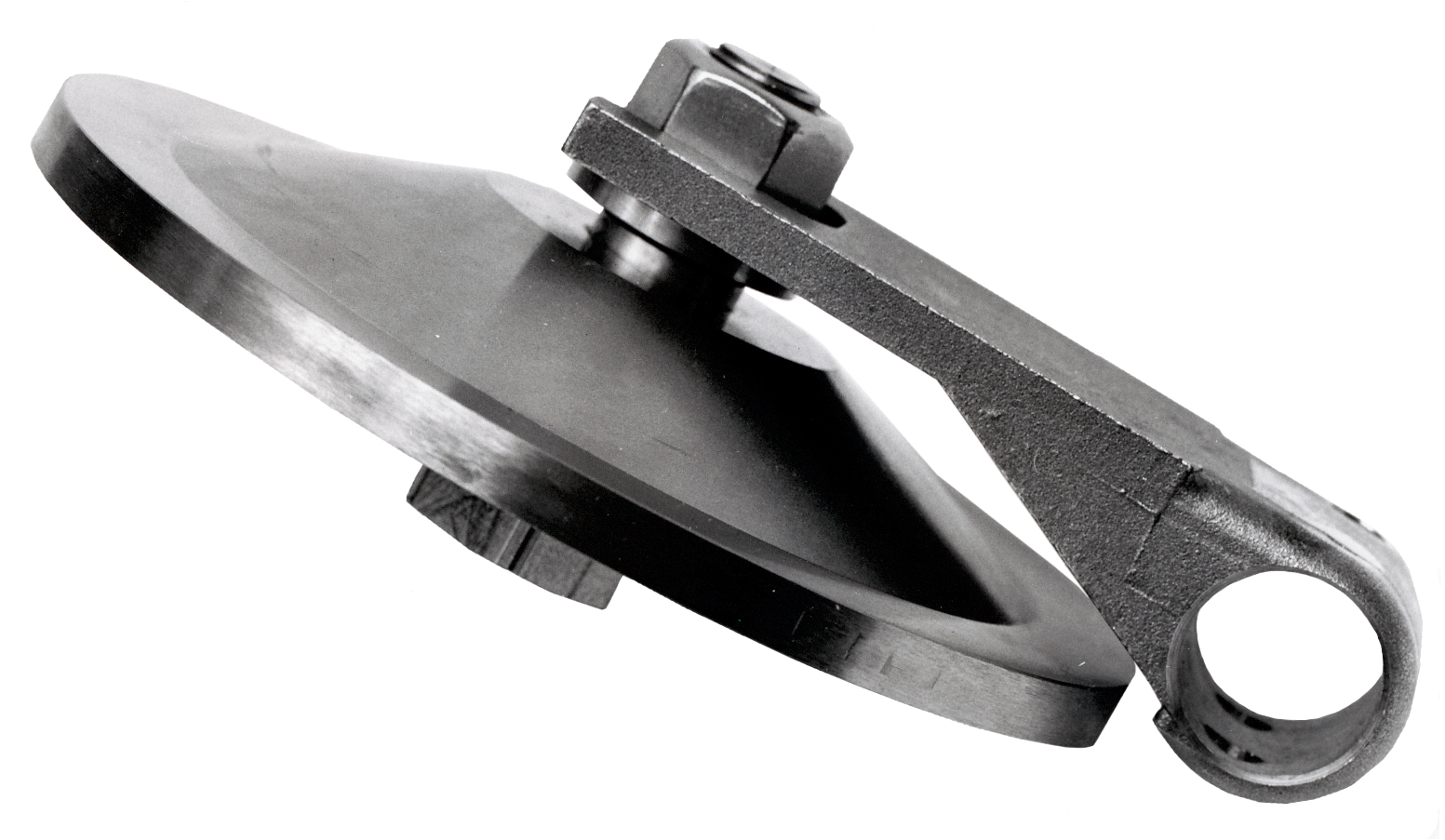

A shut-off valve may be a flapper-type or butterfly-type. The butterfly-type is good, but the disk remains in the flow path when the valve is open and acts as a restriction. The flapper-type is excellent on pressure drop, but a plain flapper cannot be opened against pressure. For this reason, our valve incorporates a “valve within a valve,” which automatically equalizes pressure when you start to move the operating handle. It is very easy to operate, yet provides all the advantages of a flapper-type valve. Other flapper-type designs rely on a separate tiny, vulnerable, manually operated valve for equalizing pressure. This is inconvenient, and it may also be accidentally left open.

The unique feature of the Gammon Under-Hydrant Shut-Off Valve is that, in addition to providing the standard shut-off feature, it can protect the airport and personnel from a disastrous fire because it closes automatically as soon as the temperature reaches 165°F (74°C). A fusible link in the chain that normally holds the valve open will melt at this temperature, resulting in instantaneous closure.

Under normal conditions, the valve can be closed easily by unhooking the chain. This action is totally independent of the fusible link. Unless the fusible link melts in a fire, it will never need to be replaced.

We usually refer to our Under-Hydrant Shut-Off Valve as an “Emergency Valve” because it will function in an emergency situation, which is usually more important to the approval authority than the basic shut-off feature. For any customer who does not need this added safety feature, we do not include the fusible link. Our valve then serves only as a “service valve,” like any other valve.

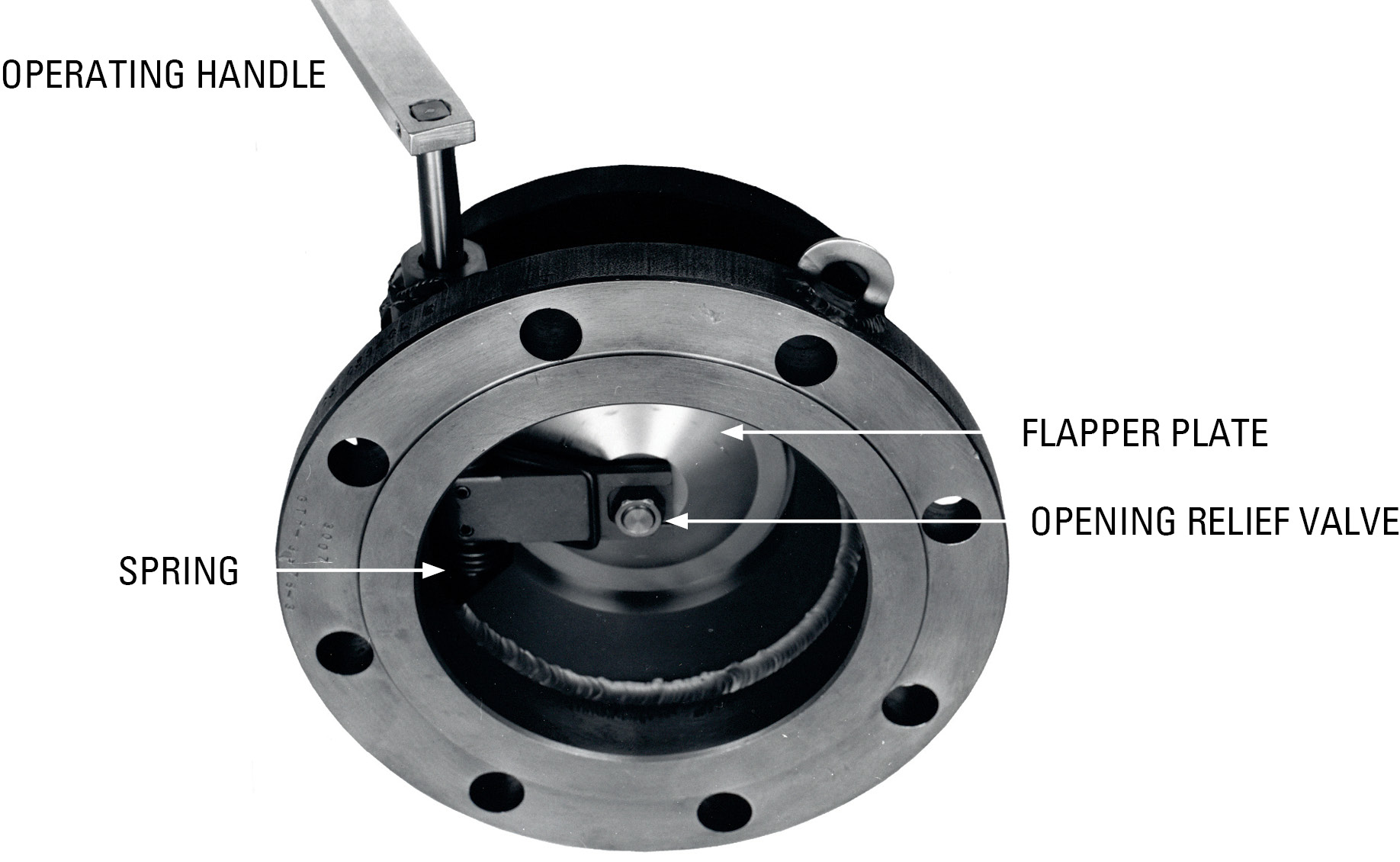

View of Device Looking Upward from Beneath the Valve

Design Features

This valve has special features that were necessary to make it pass the API-6FA fire test. This test requires that leakage through the valve or outside the valve will not exceed specified amounts after the seals have burned away at a temperature of 1600°F. To meet those specifications, we were unable to seal the operating shaft with o-rings so we used a unique labyrinth-type seal assembly that has proven to be reliable in other products we make.

Opening Relief Feature

The primary advantage of this valve is its opening relief feature. Proven in many years of service on model GTP-2654, we made no changes when this feature was applied to model GTP-3978. In the closed position, the hydrant pressure assists the spring in keeping the valve tightly closed. Therefore, to open the valve, it is necessary to bleed fuel from the pressure side into the hydrant valve. To do this, the operator applies a small constant force (about 4-5 lbs.) to the handle. This force opens an internal bleed valve which passes fuel to the hydrant valve. When the pressure in the hydrant valve equals the hydrant system pressure, the operator can easily open the main valve and then attach the fusible link chain to arm it. A competitive valve on the market today has a separate, external bleed valve that can be opened by the operator who must reach under the hydrant valve to turn the handle. After the pressure equalizes, he must remember to close that valve.

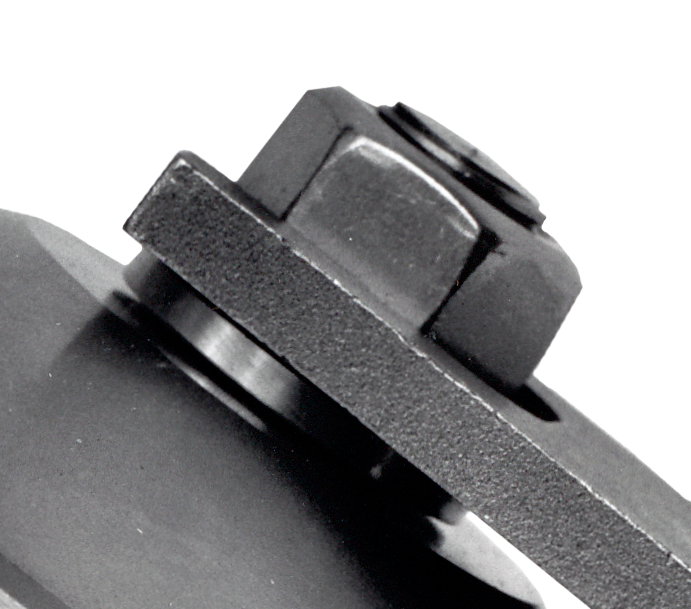

OPENING RELIEF VALVE OPEN

Note cross-drilled holes for flow.

OPENING RELIEF VALVE CLOSED

General Information

Airport design engineers in many parts of the world are specifying the features of our Model GTP-3978-3 because they achieve two objectives that a plain butterfly valve (or even a fire-safe butterfly valve) does not offer. A non-fire-safe valve offers no leakage protection. A fire-safe butterfly valve is capable of stopping fuel flow in a fire only if it is in the closed position when a fire develops.

Clearly, an under-hydrant valve is expected to be in the open position except under unusual circumstances, such as for maintenance of the main hydrant control valve. Therefore, our valve is favored because it not only serves as a maintenance valve, but also will sense the presence of a fire and then close automatically to ensure that the fire will not be enhanced by more jet fuel.

Under such a condition, the fire may develop intense heat that will destroy all of the seals in any valve whether it is a butterfly or flapper-type. However, the unique design of our valve ensures that leakage will be minimized in accordance with API Bulletin 6FA even if the seals have been burned away.

In summary, our valves are in service at a number of airports worldwide, from New York’s JFK to Singapore’s Changi Airport. We have had virtually no replacement part orders, proving that these valves require no maintenance or replacement parts.

Our valves serve as manual shut-off valves and emergency valves. All working parts are solid stainless steel. They are very heavy duty. They offer almost no resistance to flow. Samples are available upon request. Once you have seen our valve and compared it with any and all alternatives, we are confident that you will agree no equal to our valve exists.

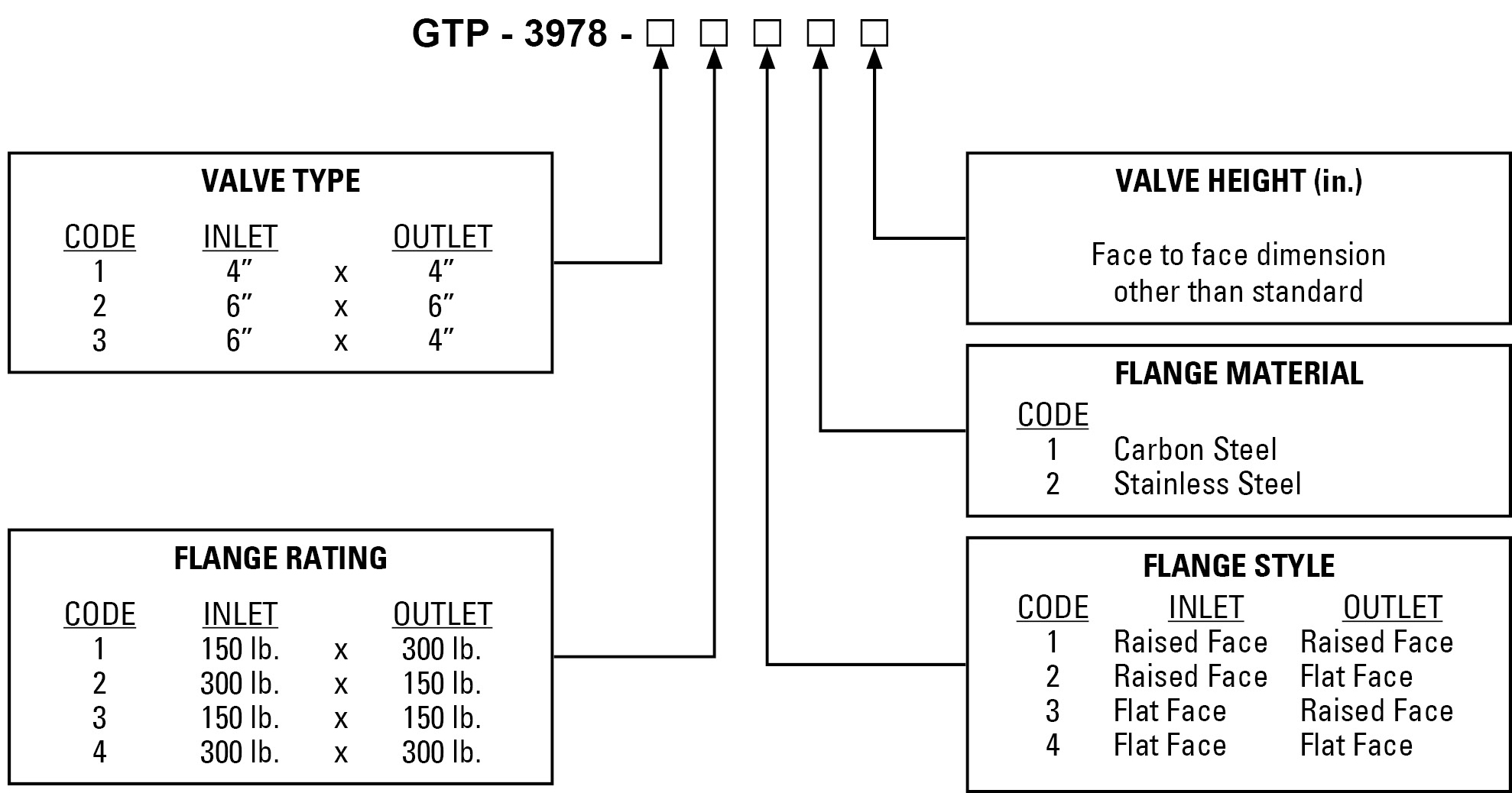

How to Order

Approximate weights: 4” x 4” 150 lb. flanges 51 lbs., 6” x 6” 300 lb. flanges 78 lbs., 4” x 6” 150 lb. flanges 47 lbs.

EXAMPLE: GTP-3978-23126 is an emergency valve as follows: 6” x 6” valve type, 150 lb. x 150 lb. flange rating, raised face flanges, stainless steel, with a valve height of 6 inches.