As described in ASTM Method D5452, the support stand is designed to hold the container that was used to collect the jet fuel sample in the field. There is no need to transfer the sample from the collection container to another container, thereby eliminating possible contamination from the second container.

Using a flexible dispensing tube assembly that fits the thread of the port in the top of the sample container, the operator closes the tube with the clip to prevent the release of fuel when the container is being turned upside-down to place it on the support stand upper shelf. The tube is then positioned in the filter tunnel before releasing it. This allows fuel to fill the funnel but it will not overflow because air must return to the container through the same tube. The filter funnel remains full in the same way that a bird feeder operates because the lower end of the tube is below the fuel surface in the funnel.

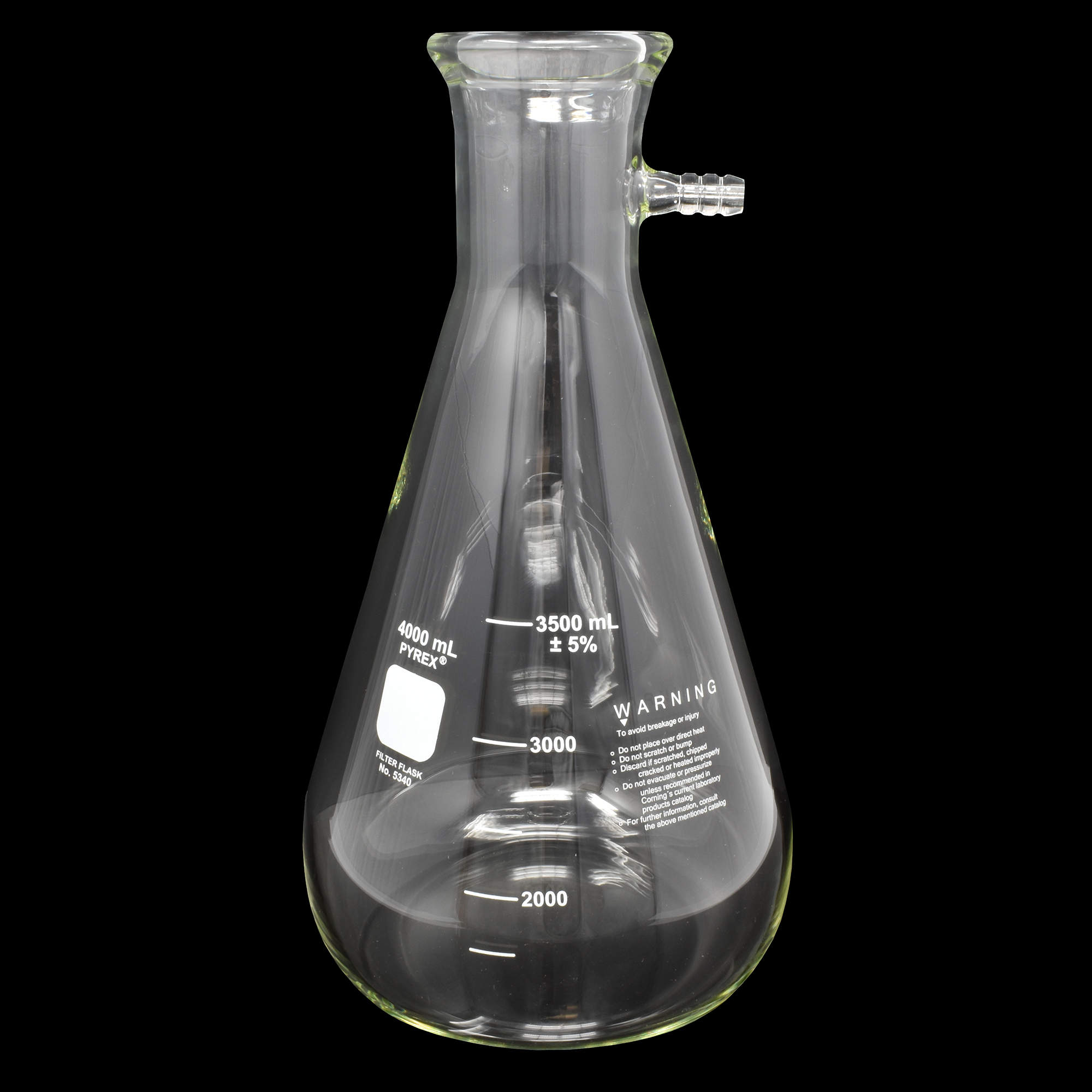

Vacuum in the collection flask draws fuel through the membrane filter desk that is positioned at the base of the filter funnel. Hands-free operation is assured. The operator is no longer required to hold the container as fuel is poured into the filter funnel. The potential for spillage is virtually eliminated.

How to Order

Complete Apparatus

Apparatus Components

Optional Accessories (to be ordered separately)

This type of 1-liter dispenser is specified in various ASTM test methods such as D-2276 and D-5452 which are used to determine the weight of contaminants that are in fuel samples.

One dispenser is recommended for isopropyl alcohol to flush particles off of laboratory apparatus before it is used to insure that those particles are not included as contamination in the fuel sample.

A second dispenser is used for petroleum spirit (either) to flush residual particles out of the sample container and off of the funnel that was used to deliver the fuel sample from its container onto the filter membrane after the container contents have been passed through it.

Both dispensers are equipped with filter housings to remove particles from the isopropyl alcohol and from the petroleum spirit. A packet containing 10 of 0.4533 membranes (25 mm diameter) are included with each dispenser. Replacement membranes are available in a packet of ten (order GTP-9582).

The squeeze bulb develops pressure in the 1 liter flask, forcing fluid into the tubing and through the filter membrane. Gammon Technical Products manufactures the aluminum filter housing and membrane support using reagent resistant materials.