Defueling Eductor

TL-8856

When defueling aircraft, the safest method is to use an eductor. This device generates flow and a mild vacuum. This allows the truck to defuel aircraft at a controlled rate and a controlled vacuum, to protect the aircraft. Excess vacuum can cause damage to the aircraft fuel tanks, which are often part of the wing. The primary adjustment is made by controlling the pump

speed/flow rate on the refueler.

The TL-8856 eductor is designed to match or exceed the performance of other eductors on the market and do so with one less gasket and a lower price. Our eductor is rated up to 280 gpm. In addition, it is cast of 356-T6 aluminum, 100% made in the USA.

3” x 3” x 2” IPS (Victaulic)

Recovery Tank Eductor

GTP-486-5

Recently redesigned for even greater performance, this eductor is designed for recovering clean fuel from an expansion/recovery tank on a refueling vehicle. For optimal performance, the suction line should be 1/2” pipe or tubing at a minimum and the suction line ball valve should be 3/8” full port or 1/2” standard port. 100% made in the USA, aircraft grade aluminum.

3/4 NPT x 1 NPT x 3/8 NPT

Venturis

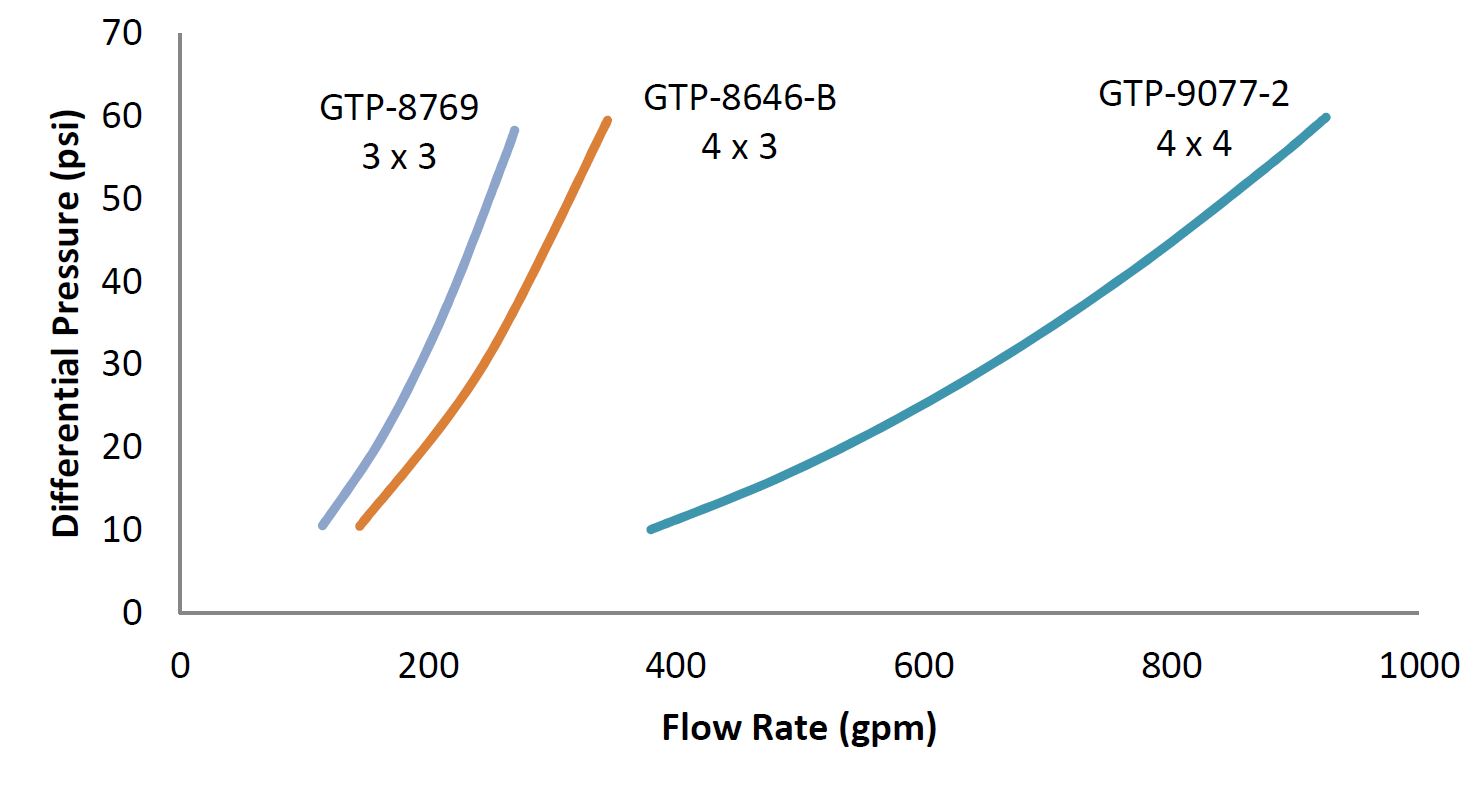

To refuel aircraft at the highest possible flow rate, a refueling vehicle must control the pressure accurately at the nozzle to approximately 45 psi. Because of pressure drop in the hose reel and hose, a system flowing at 300 gpm with 45 psi at the nozzle has to have a much higher pressure at the host reel inlet. But pressure drop changes with flow rate. For this reason, Venturis are used to automatically “compensate” for this pressure drop.

As velocity increases, the small opening at the center of the venturi has higher and higher velocity. As the inventor, Giovanni Venturi, discovered over 200 years ago, the pressure decreases as velocity increases. Using careful mathematics, a Venturi can create a “false signal” that can be tuned to match the actual nozzle pressure (or it may be higher in some cases, on the “safe side” with actual nozzle pressure lower). See our GamGram #32.

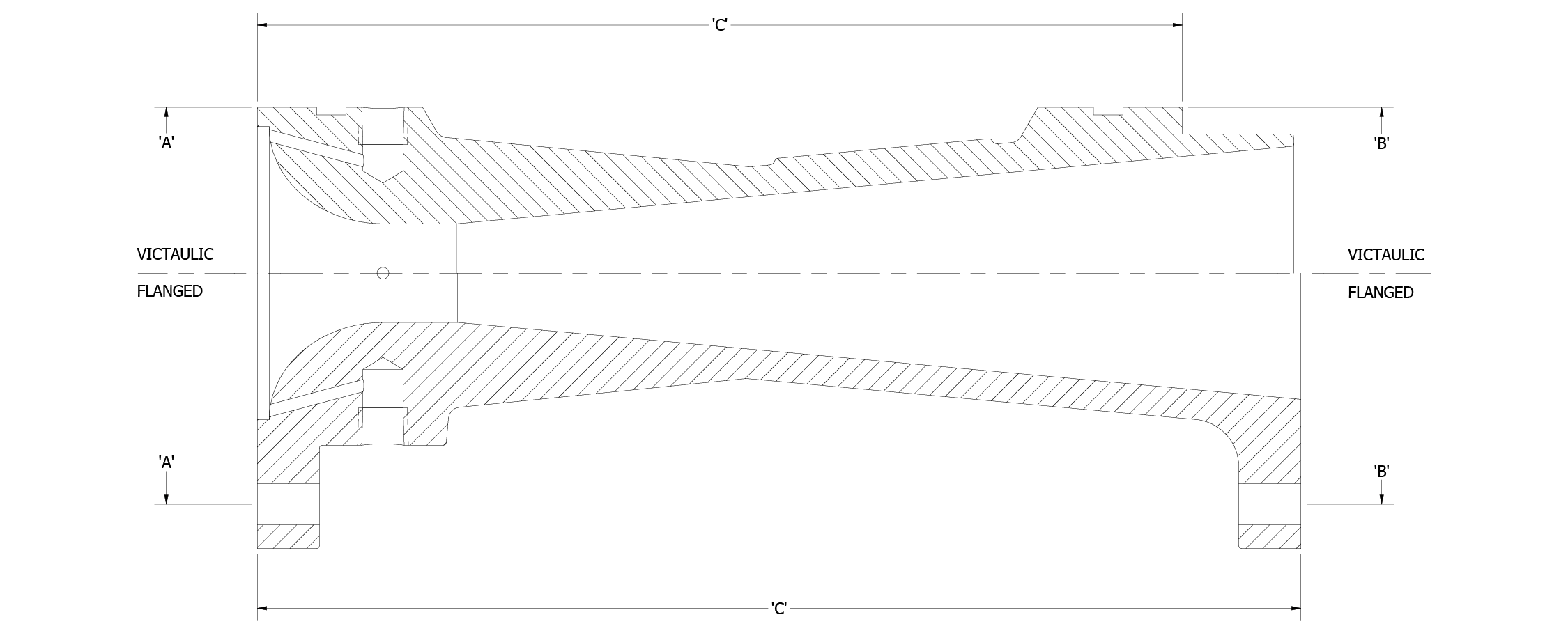

The primary venturi we sell is the 3” x 3” GTP-8769 venturi, made with either flanged (TTMA) or Victaulic connections. It is the highest performance 3” venturi we know of, specifically tuned for 300 gpm. We also make the GTP-8646-B 4” x 3” Venturi with Victaulic connections only.

All Gammon Technical Products venturis are cast and machined in the USA and are 356 T6 aluminum, impregnated against leakage. Rated for up to 150 psi system pressure. Needle valve not included.

| Part No. | End Style | Inlet ‘A’ | Outlet ‘B’ | Length ‘C’ |

|---|---|---|---|---|

| GTP-8769 | Victaulic | 3″ | 3″ | 9.75″ |

| GTP-8769-3 | TTMA Flanged | 3″ | 3″ | 11″ |

| GTP-8846-B | Victaulic | 4″ | 3″ | 14.1″ |

| GTP-9077-2 | Victaulic | 4″ | 4″ | 14.1″ |