About Sandra Gammon

This author has not yet filled in any details.So far Sandra Gammon has created 139 blog entries.

GamGram 34: El Fantasma que Taponea las Tuberías y Otras Historias Aterradoras

Una de las grandes verdades relacionadas con el control de la calidad tiene que ver mucho con el famoso refrán de que “en la confianza está el peligro”. Por muy insignificante que sea una falla, hay que prestarle atención y así evitamos males mayores. Si su instalación es de la que no tiene problemas debes ser más cuidadoso pues como está confiado los problemas son más difíciles de detectar.

En cualquier negocio los problemas que surgen no suelen ser divulgados al mundo, desafortunadamente, esta práctica dificulta que otros aprendan de estos errores. Este GAMGRAM reúne pequeñas historias sobre problemas que han sufrido otras personas ofrecemos a oportunidad de aprender de estos avatares y obviamos nombres y ubicaciones innecesarios y para evitar bochornos. Hemos hecho todo lo posible para contar las historias con la mayor precisión, aunque algunas se sustentan en información de segunda mano. Los problemas son reales y pueden ocurrir en cualquier lugar.

1. ¡Cuidado con el Fantasma que Taponea las Tuberías!

En casi todos los almacenes o concentrados de combustible de los aeropuertos existe un “fantasma”. El cual se caracteriza por colocar un tapón en cada accesorio que tiene salidero o resume combustible: En el eliminador de aire de los filtros, la Válvula de alivio de presión, el drenaje manual y el drenaje automático de agua. Si observa con detenimiento alrededor de sus instalaciones es probable que encuentre alguno de estos arreglos “temporales,” cuya presencia conlleva a un peligro mayor de lo que imaginas. A continuación exponemos varios ejemplos:

- Un tapón colocado en una válvula de alivio de presión puede causar una ruptura incrementando las fugas. Un tapón colocado en la salida del eliminador de aire de un filtro puede mantener el aire atrapado en el interior de la carcasa y provocar un incendio interno o explosión (ver GamGram 15).

- Taponear la ventilación de control flotante o en la válvula de drenaje automático de agua constituye un grave error y un peligro muy grade (a menudo, la ventilación se conecta al lado de salida de esta válvula (ver GamGram 10, GamGram 11, y GamGram 12.).Esto puede impedir el funcionamiento del control para la acumulación de agua y la válvula de cierre. Asegúrese de que las fugas sean reparadas, no taponeadas ¡RECUERDE QUE TODOS LOS CONTROLES CON FLOTANTE DEBEN TENER VENTILACIÓN!

2. Apogado de los Motores

En una ocasión un carro cisterna (repostador) estuvo estacionado sin usarse durante varios días lluviosos en un importante aeropuerto de EE. UU. La junta de la escotilla o registro de acceso del tanque se había deteriorado y el mecánico debió reemplazarla. Al tratar de cambiarla no pudo retirar la junta vieja por completo y por ello pegó la nueva sobre los restos de está quedando sobre una la superficie irregular y este fue un sellaje imperfecto. Las mangueras de evacuación colocadas en el canal de desagüe debían drenar el agua de lluvia del techo del tanque el cual estaba tupido con hojas de árboles y otros desechos. Por otro lado el flotante de la válvula para el control de nivel de agua en el pocillo del filtro separador no había sido verificado y además, el mecanismo del flotante de la válvula para control de agua colocada en el pocillo del filtro separador no se desplazó como es debido y no se detectó debido a que esta válvula no fue probada durante un largo periodo de tiempo.

El operador de dicho equipo, tomó una muestra para control de calidad del sumidero del filtro separador y obtuvo como resultado un combustible de calidad, limpio y seco, sin embargo no le fue posible tomar una muestra del combustible contenido en la cuba porque la válvula interna de fondo estaba cerrada ya que solo se abre cuando se conectada la PTO (accionamiento de la toma de fuerza para conectar la bomba), por esta razón el agua que se escurrió dentro del tanque con las lluvias pasó desapercibida.

Dos aeronaves fueron reabastecidas de combustible con este repostador. La primera despegó sin problema; sin embargo los motores dela segunda se apagaron en la calle de rodaje. Por suerte alguien muy inteligente inmediatamente llamó por radio al primer avión el cual que hizo un aterrizaje precautorio. Se drenaron más de 100 galones de agua de cada uno de estos aviones. Fue una llamada muy oportuna.

Conocemos al menos siete historias similares. En una de ellas, se tomó una muestra del tanque del ala del avión y como el frasco con el que se realizó el muestreo aún olía a combustible (¡por haberse usado con anterioridad) el operador pensó que era combustible al verlo claro y trasparente; sin embargo, era pura agua. En otro caso, se realizó el ensayo tomando la muestra del drenaje de la cuba, pero debido a que el repostador estaba estacionado en una pendiente, el agua se había desplazado al lado contrario de la toma de drenaje y por eso no se detectó. En otro caso, la nieve y el hielo obstruyeron las mangueras de desagüe del techo de la cuba.

Moralejas:

- Debe realizar los controles para detectar agua, en las muestras tanto de la cuba (tanque) como de los sumideros del filtro separador. .

- Mantener destupidas las mangueras de drenaje del tanque.

- Chequear las juntas del registro de hombre que estén en buen estado.

- Usar un colorante para alimentos (bijol, azafrán) o verter café en la muestra tomada de combustible para asegurarse de que no sea 100 % agua ya que ambos se diluyen en el agua pero no en el combustible.

3. Concreto

En un aeropuerto de magnitud media, un camión cisterna de combustible de aviación realizó una entrega normal. La terminal desde donde salió el combustible, el conductor y el camión cisterna pertenecían todos a la misma empresa petrolera, muy conocida y de gran prestigio. Durante 20 años el l concentrado o almacén había estado en el negocio sin un solo problema con el combustible. De alguna manera, el papeleo en el tráiler se mezcló con otro. Debido a la complacencia causada por su perfecto historial de seguridad, el ensayo de control de calidad con la cubeta blanca no se le realizó a cada compartimento. La bomba funcionó durante unos segundos y se detuvo. Parece que un grado particular de fertilizante líquido se transformó en una sustancia sólida similar al hormigón al mezclarse con el combustible.

Moraleja: ¿Qué hubiera pasado si en vez de ser ese fertilizante hubiera sido un producto que pudiera pasar la bomba ingresando al sistema, como la acetona o el barniz?

4. ¡Boom!

En un concentrado (almacén) de combustible perteneciente a un aeropuerto grande, se tomaba una muestra del sumidero de cada carcasa filtrante y de cada tanque al comienzo de cada turno. En una ocasión una parte del sistema estuvo fuera de servicio temporalmente, sin embargo el filtro separador seguía siendo muestreado tres veces al día. Y cuando el sistema se puso en servicio nuevamente, la carcasa del filtro separador estaba vacía pues había sido purgado todo el combustible. Cuando se encendió la bomba, el combustible circulo a un caudal de 600 GPM con alta presión a través de los elementos coalescedores que estaban dentro del filtro vacío, entonces en ese instante se reunieron las tres condiciones propicias: oxígeno y vapores de combustible atrapados, descarga electrostáticas producidas en el filtro coalescedor, y de repente.¡¡\BOOM!! Déjenme decirles que tomó algún tiempo encontrar la carcasa pues, había caído en un campo al otro lado de la carretera.

Han ocurrido explosiones e incendios similares en numerosas ocasiones, ya que el operador no llenó la carcasa del filtro lentamente después de haber realizado el cambio de elementos filtrantes, o porque se permitió que una bomba de desplazamiento positivo funcionara durante la descarga de un camión cisterna después de este haberse vaciado bombeando aire en lugar de combustible. Las carcasas de filtros verticales son más susceptibles a este tipo de problemas que las horizontales.

Moraleja: ¡Varias y obvias!

5. 8,000 Galones en un Camión de 5,000 Galones

El operador de un camión repostador estaba muy cansado. Según los informes, estuvo trabajando al final de un doble turno. Llevó su camión al concentrado de combustible para ser rellenado, conectó la manguera de carga por el fondo y bloqueó la manilla de hombre muerto (Deadman). Volvió a sentarse en la cabina del camión por un minuto y se durmió. ¡El control de sobrellenado en la cuba (tanque) del camión falló y el conductor se despertó con un gran desastre!

Moraleja: ¡Varias y obvias!

6. Confianza Fuera de Lugar

Un inspector de una importante compañía petrolera estaba en una inspección de rutina de su mejor base operativa. El gerente de esta se enorgullecía de superar todos los requisitos del control de calidad con su propio sistema, incluido un hombre escogido al azar el cual estaba cuidadosamente seleccionado y capacitado. El inspector sabía que tenía que examinar a conciencia de todos modos. Se dio cuenta de que la manigueta de la bomba manual para la extracción de drenaje en un tanque subterráneo no se movía porque estaba atascada; el gerente se avergonzó pues al cambiarla por una nueva bomba produjo 20 galones de agua sucia. Pidió la hoja de verificación de ese punto y esta mostraba había sido drenado 4 horas antes y no tenía observación a alguna de presencia de agua.

Moraleja: ¡Obvias!

7. ¡¿No Hay Caída de Presión?!

Un gaseador (operador de línea de vuelo) se quejó con el mecánico de que el caudal del camión para el suministro de AVGAS (gasolina de aviación) era demasiado bajo. El mecánico revisó el problema y encontró un caudal de menos de 5 GPM. En una inspección más profunda, descubrió que la caída de presión real del filtro era superior a 90 psi debido a que el caudal se había reducido debido al diferencial de presión. El operador manipulo el control de presión por lograr un caudal más alto había ajustado el control de presión de derivación de la bomba para obtener más flujo, pero el mecánico no se percató del asunto porque la bomba estaba tan desgastada que solo entregaba 25 psi al ralentí del motor (el mecánico revisó el camión al ralentí). Cuando accionó hacia afuera la palanca del acelerador de la PTO (toma de fuerza), tratando de obtener más caudal, la presión superó los 90 psi. Se utilizó una válvula selectora de 90 grados y un manómetro para determinar la caída de presión. Al no estar las posiciones de las válvulas marcadas, nadie obtuvo buenas lecturas. (Ver GamGram 1). Todas las lecturas del diferencial de presión se habían tomado con el motor en ralentí.

Al realizar el estudio de los registros de caída de presión mostró 1 psid por cada lectura durante los 2 años (todas imprecisas).

Moraleja: Revisar tu equipo y personal. No confíe en registros consistentes. Sin variaciones.

Imposible encontrar humor en estas historias. En realidad la probabilidad de un desastre es remota pues por lo general, tienen que ocurrir varios errores o fallas a la vez para llegar a una catástrofe. La pregunta es: Vivirías tranquilo al saber que eres responsable de la muerte o sufrimiento de un grupo de personas?. Las tenciones no bastan; lo importante es la acción. Un accidente al año en todo el mundo es demasiado.

POLÍTICA EQUILIBRADA– En la Antigüedad, era política matar al mensajero portador de malas noticias. Suponemos que no todo es malo ¡Pasó la noticia! ¡NO PUEDO HACER ESTO!

Revise sus métodos y no haga que el castigo por un error sea igual al castigo por encubrirlo Esto tiene que ver sobre todos con los derrames de combustible y otras situaciones legales y relacionadas con la seguridad. Hemos oído hablar de personas que trataron de ocultar las pérdidas de combustible para proteger sus trabajos! En un ejemplo, un empleado lavó el combustible en una corriente, lo que resulta en un desorden mucho más grande para limpiar. ¡El gobierno vera esto como su culpa y puede imponer multas mayores!

GamGram 34: The Pipe Plug Phantom and Other Frightening Stories

One of the truths of quality control is that the better it is, the easier it is to take it for granted. When you have very few problems, it is hard to be as careful as you should, and the problems you do have are more difficult to anticipate. In any business, you do not announce your problems to the world, and unfortunately, this makes it difficult for others to learn from your mistakes. This GAMGRAM is a collection of stories about problems other people have experienced. You may learn from their mistakes. To avoid embarrassment, no names or locations are given. We have tried our best to tell these stories accurately, although some are based on second hand information. The problems are real and can happen anywhere.

1. Beware of the Pipe Plug Phantom!

At nearly every airport fuel terminal there is a “phantom”. The “phantom” puts a pipe plug in every leaking air eliminator, pressure relief, manual drain and automatic water drain valve. Look around your facility, and you will likely find these “temporary” fixes. The danger can be greater than you think. A plug in a pressure relief valve can cause more leaks or a rupture. A plug in an air eliminator can keep a filter vessel full of air causing an internal fire (see GamGram 15). A great danger is a plug in the float control vent or automatic water drain valve (often the vent is piped into the outlet side of this valve; see GamGram 10, GamGram 11, & GamGram 12). This can prevent operation of an otherwise functional water control and slug valve. Be sure leaks are fixed, not plugged

REMEMBER: ALL FLOAT CONTROLS HAVE TO HAVE A VENT!

2. Flameout

At a major US airport, a refueler truck was parked unused for several rainy days. The manway gasket had deteriorated, and a mechanic had to replace it. He was not able to entirely remove the old gasket and glued the new one over this uneven surface. The result was an imperfect seal. The trough hoses that were supposed to allow rain water to drain from the tank roof had been plugged with leaves and other debris. In addition, the float operated water control on the filter separator had not been tested in a long time and the mechanism was not able to move smoothly.

The driver went to the truck, took a sump sample from the filter separator and got good, clear jet fuel. He could not or did not take a cargo tank sample. Since the internal valve was not open (it opens when the PTO [power take off pump drive] is engaged), the water in the cargo tank went undetected. Two aircraft were refueled. The first one took off without a problem. The second flamed out on the taxiway ramp. Some very smart individual immediately radioed the first aircraft which made a precautionary landing. Over 100 gallons of water was drained from each of these aircraft. It was a very close call indeed.

We know of at least seven similar stories. In one, a sample was taken from the wing tank and since the jar still smelled of fuel from past use, the operator thought it as “water white” jet fuel! In another case, the cargo tank drain was operated, but because the refueler was parked on a slope, the water had run to one end. In still another case, snow and ice plugged the drain hoses from the tank roof.

The morals are: These water controls, get tank and filter sump samples, keep drain hoses and manway gaskets well maintained and use food coloring dye or spill coffee into a sample to be sure it is not 100% water.

3. Concrete

At a mid-sized airport, a transport truck made a normal delivery. The terminal, driver and truck were all from a major oil company. The FBO had been in business for 20 years without a single fuel problem. Somehow, the paperwork on the trailer was mixed up with another. Because of complacency caused by their perfect safety record, white bucket samples of each receipt load were not taken. The pump ran for a few seconds and stopped. It seems that one particular grade of liquid fertilizer turns into a solid similar to concrete when mixed with jet fuel.

Moral: Obvious. But what if it had been a product that could go through the system, like acetone or varnish?

4. Boom!

At a large airport fuel farm, every filter vessel and tank had a sump sample taken at the beginning of each shift. When a particular system was temporarily shut down, the filter separator was still sampled three times a day. By the time that system was needed again, the vessel was empty. When the pump was started, 600 gpm of fuel at high pressure sprayed out of the coalescers into an empty vessel full of air. Fuel, oxygen and electrostatic charges caused by the elements were present and BOOM!! It took some time to find the vessel cover, it was in a field across the road.

Similar explosions and fires have occurred numerous times, because the operator did not fill the vessel slowly after an element change or because a positive displacement pump was allowed to run after a transport truck was emptied, thus pumping air instead of fuel. Vertical vessels are more susceptible to this type of problem than horizontal vessels.

Moral: Several and obvious!

5. 8,000 Gallons in a 5,000 Gallon Truck

A refueler truck driver was tired. He was reportedly working the end of a double shift. He pulled his truck into the fuel farm, hooked up the loading hose and jammed the deadman handle. He went back to sit in the cab for a minute and fell asleep. The overfill control on the truck failed and he awoke to one heck of a mess!

Moral: Obvious!

6. Misplaced Trust

A major oil company inspector was on a routine inspection of his best FBO. The manager took great pride in exceeding all Q.C. requirements with his own system, including a hand-picked and trained field man. The inspector knew he had to actually inspect anyhow, and it’s a good thing. He noticed that the handle of the thief pump on an underground tank would not move. The manager was very embarrassed when a change of pumps yielded 20 gallons of dirty water. The check sheet showed no water from that thief pump which supposedly had been tested four hours earlier.

Moral: Obvious!

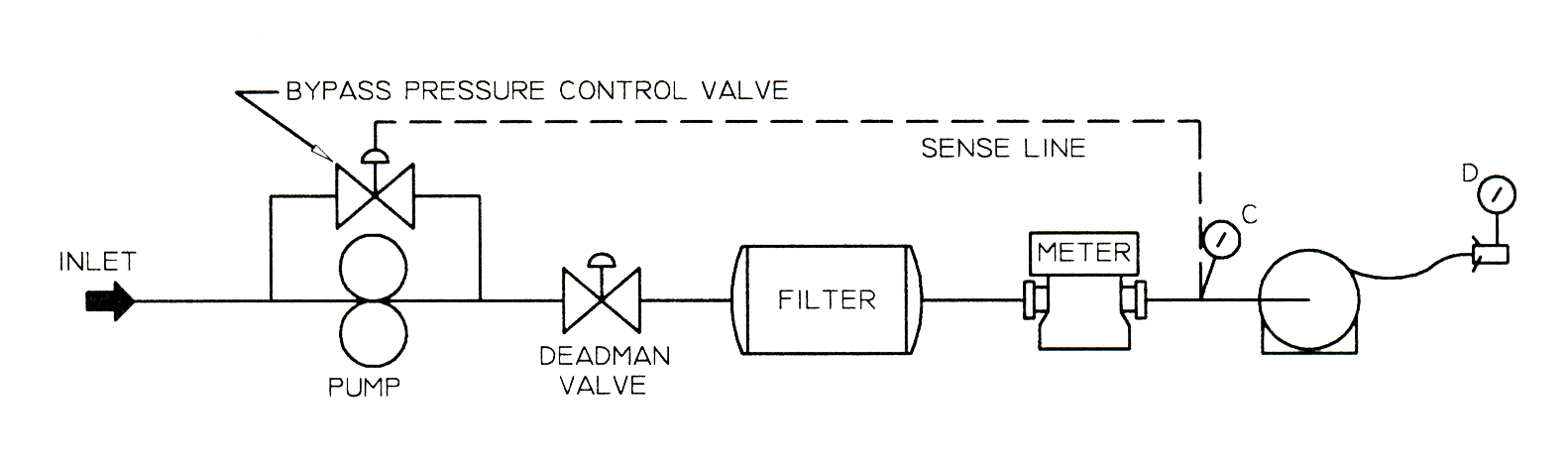

7. No Pressure Drop?!

A lineman complained to the mechanic that the avgas truck flow rate was too low. The mechanic checked out the problem and found a flow rate of less than 5 gpm. On further inspection, he found that the actual filter pressure drop was over 90 psi (no error). Because flow rate had slowed due to high pressure drop, a driver had adjusted the pump bypass pressure control to get more flow, and the mechanic did not notice, because the pump was so worn that it only delivered 25 psi at engine idle speed (the mechanic checked the truck at idle). When the operator pulled the PTO (power take off) throttle lever out, trying to get more flow, pressure went over 90 psi. A 90 degree selector valve and gauge were used to determine pressure drop. Because the valve positions were not marked, no one got good readings. (see GamGram 1). All readings had been taken at engine idle.

A study of the pressure drop records showed 1 psid for each reading for the 2 years (all inaccurate).

Moral: Check your equipment and personnel. Do not trust consistent records.

It is not possible to find humor in these stories. The chance of disaster is remote. Usually several errors, failure or mistakes have to occur simultaneously for a disaster. The question is, could you live with yourself if you were responsible for death or suffering? Intentions are not important, performance is. One accident a year worldwide is one too many. We have come too close to major disasters in the past — it can happen.

BALANCED POLICY – In ancient times, it was policy to kill the messenger that brought bad news. We assume that not all bad news got through! CAN’T DO THIS! Review your methods, and don’t make the punishment for a mistake equal to the punishment for covering up a mistake. This especially applies to fuel spills and other legal and safety related situations. Don’t laugh, we’ve heard of people who tried to hide fuel spills to protect their jobs! In one example, an employee washed the fuel into a stream — resulting in a much larger mess to clean up. The government sees this as your fault and may levy larger fines!!

GamGram 33: Válvula Controladora de Presión de Final de Manguera

La forma más segura de evitar que un caballo no se fugue de su finca es manteniendo las puertas del establo bien cerradas. Piense en la válvula de control de presión de punta de la manguera en inglés Hose End Control Valve (HECV), esta sería la “puerta del establo”. Pudiera atar el caballo a una cuerda sujeto a una estaca, pero si la cuerda se rompe o se zafa, el caballo sale por la puerta si está abierta, Bajo esta analogía piense en la “cuerda” como el análogo de la válvula de control de presión en línea del vehículo de reabastecimiento de combustible.

En la actualidad las especificaciones para los vehículos de suministro de combustible se requieren dos controles para la presión de combustible separado e independiente: Uno respalda al otro en caso de fallo ¡La puerta y la cuerda ofrece mejores probabilidades! La válvula HECV es el método menos costoso de todos los dispositivos de control de presión en el mercado y se ha vuelto muy popular como control secundario (aunque en Europa la utilizan como control primario).

Esta válvula comenzó a usarse en la década de los años 60 al elevarse el consumo de combustible en aeronaves y el caudal de abastecimiento aumento en consecuencia, entonces la industria reconoció la insuficiente atención que se le estaba prestando al control de la presión durante el suministro y, en particular, a la prevención de los picos de presión en la aeronave. El primer producto en el mercado fue una boquilla de abastecimiento de gran dimensión y peso con un dispositivo de control de presión integral. Sin embargo el complejo dispositivo dio paso rápidamente a la HECV que conocemos en la actualidad. Existen al menos cuatro versiones disponibles de este dispositivo; pero en este boletín haremos hincapié en la variedad más popular que está hecha por Carter Ground Fueling, división de Argo-Tech y Whittaker, división de Meggitt.

Antes de describir el funcionamiento de la HECV, debemos aclarar un aspecto. Si quiere medir longitud, presión, peso, luz, etc., debe tener un punto de partida razonable, una “línea de base”, un dato específico; por ejemplo, la altura de una persona no se mide desde su nariz! entonces si deseas medir la presión en un sistema de combustible, el único punto de partida será la presión atmosférica. Esto sucede porque utilizamos ese dato como referencia o sea si un manómetro de presión de aceite en un motor indica 100 psi, eso significa 100 psi por encima de la presión atmosférica.

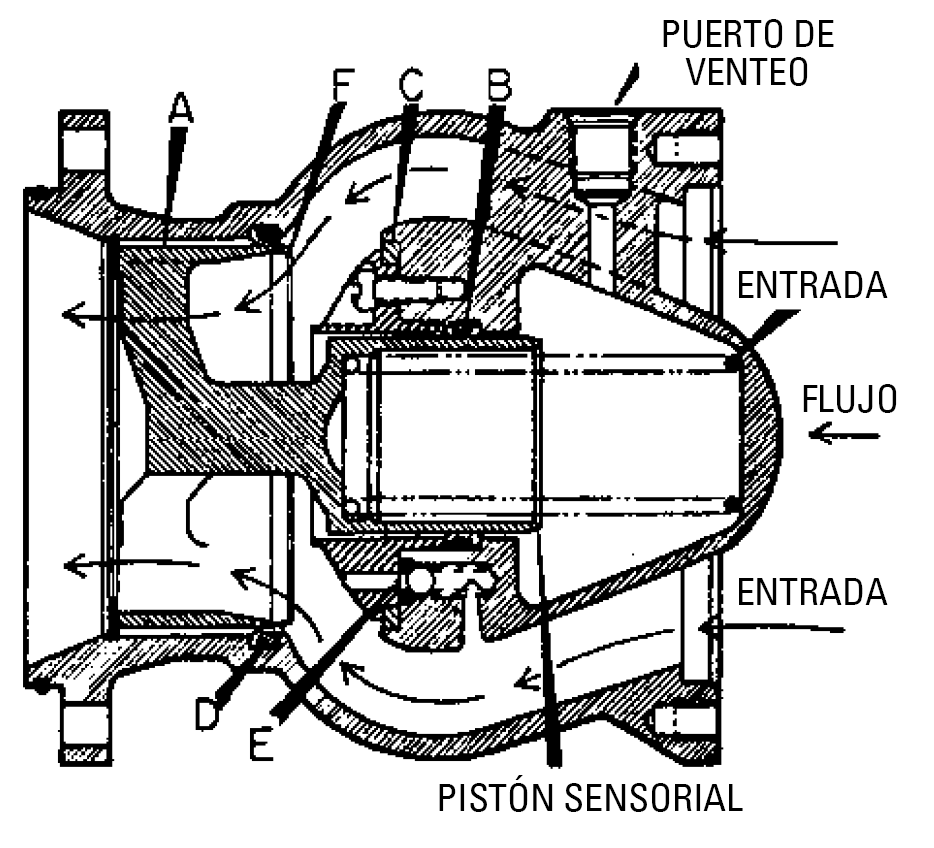

En los sistemas de combustible se debe usar la presión atmosférica como nuestra base o dato. Si la válvula HECV controla a presión de nuestro sistema a un máximo de 45 psi, esto significa que la presión del mismo está a 45 psi por encima de la presión atmosférica. Pero ¿cómo es que la válvula sabe cuál es la presión atmosférica? Lo explicamos, Obviamente esto se logra a través del puerto de venteo el cual canaliza la presión atmosférica hacia un lado del pistón sensorial.

Observe el dibujo y si del otro lado del pistón está actuando en contraposición la presión ejercida por el combustible, entonces estamos en presencia de un dispositivo para medir la presión y si le adicionamos un muelle en el lado de baja presión (presión atmosférica); entonces la presión del combustible es equivalente a la medida en que se comprime el resorte. Al tener la base establecida, entonces al observar el dibujo vemos que cuanto más se mueve hacia atrás el pistón sensorial también se comprime el resorte y resulta más pequeño el pasaje entre el labio F y el sello C por el cual el combustible debe pasar. El anillo exterior A conocido popularmente como el “pistón exterior” (aunque en realidad no es un pistón), está unido al pistón sensorial mediante una estructura de redes cruzadas (tipo cortador de galletas), al cerrar el pasaje lo que hace es cortar el flujo de combustible y con esto provoca una caída de presión: mientras más obstruye el flujo de combustible, menor será entonces la presión del combustible aguas abajo de la válvula.

Aclarado el funcionamiento y cómo acciona la válvula HECV, ¿qué pensaría de un operador que puso un tapón en el puerto de ventilación, porque detecto una fuga de combustible a través de ese puerto y quiso detenerla? ¡Realmente esto sucedió! y por supuesto, la válvula HECV luego de hacerle eso dejó de funcionar debido a que no tenía forma de acceder y detectar la presión atmosférica. Lo correcto que había que hacer en ese caso para detener esa fuga era reemplazar sello B el cual evita que el combustible pase a esa cámara.

Al retornar a la analogía del caballo en un corral y su comparación con la válvula HECV como la puerta que evita el escape. Donde dijimos además que la cuerda con que se ata el caballo podría considerarse en similitud a la válvula de control de presión en línea (ILCV). El funcionamiento correcto de estas dos válvulas se debe comprobar periódicamente en lo referente a la válvula HECV esto no resulta difícil porque todo lo que se necesita es un manómetro colocado en el puerto lateral de la boquilla o en una conexión aguas abajo.

Ahora analicemos cómo se pude verificar la válvula reguladora de presión en línea conectada en el sistema de suministro del camión. Este proceso es más difícil porque no hay puerto disponible para montar un manómetro antes de la HECV. Lo que se hace en este caso es simular una falla en la HECV como si no trabajara correctamente (se soluciona utilizando un bloqueador), y entonces podemos comprobar el trabajo de la válvula de control en la línea, siendo capaz de regular la presión en la boquilla de abastecimiento. Una forma sencilla de bloquear la acción de la HECV es a través de un tubo con desconexiones rápidas en ambos extremos del pistón que lo que hace es proporcionarle temporalmente la presión de combustible en el puerto de ventilación; de esta forma se evitá que el pistón detecte la presión atmosférica al tener la misma magnitud de presión en ambos lados del pistón sensorial por lo que no puede funcionar.

Desafortunadamente, este simple método para el ensayo crea una situación adversa pues hace que el puerto de ventilación (normalmente seco) se humedezca con combustible, por ello, una vez terminada esta prueba, es una buena práctica hacer funcionar la HECV varias veces para expulsar el combustible que pudiera quedar dentro de la misma por detrás del pistón; esto evita que en el futuro reciba reportes falsos de que la válvula tiene salidero a través de ese puerto. Para evitar este efecto secundario, en los últimos años, los fabricantes han ideado dispositivos de bloqueo que interfieren mecánicamente con el movimiento del pistón. No se necesitan tubos y tampoco se humedece el puerto de ventilación.

Ahora surge la pregunta de cómo determinar si el resorte esta con condiciones y no ha perdido parte de su fuerza o si alguno de los sellos en el HECV necesita reemplazo. Claramente, si el sello B tiene fugas, podemos ver fácilmente la fuga de combustible a través del goteo en el puerto de ventilación. Pero ¿cómo se prueban los sellos C y D?, Para esto se coloca un manómetro en el puerto lateral de la boquilla, o en la tubería aguas abajo con la ayuda de un banco de pruebas. La mejor manera de ejecutar estas pruebas es presurizar el sistema con una bomba manual de pistón, ya que le permite aumentar la presión de forma estable muy lentamente. Un equipo como el que se utiliza para comprobar mangueras (GTP-2157-A) sirve para este propósito, pero solo si se conecta aguas arriba del HECV y aguas abajo de la válvula de control en línea que está a bordo del vehículo. A medida que bombea el combustible, el manómetro del probador de mangueras y la presión de la boquilla serán casi iguales hasta que el pistón exterior toque el sello C. Si los sellos C, D y E no tienen fugas, a medida que aumenta la presión del probador de mangueras a 100 o 200 psi, la presión en la boquilla debe mantenerse con la magnitud correspondiente al tipo de resorte utilizado el cual es calibrado para diferentes presiones. Sí la presión de la boquilla se mantiene a una magnitud de más de 3 psi diferente al ajuste que esta calibrado el resorte, es posible que necesite un resorte nuevo.

Es ahora cuando corresponde el turno a otra de las partes de la HECV la válvula de alivio de presión señalada en el dibujo como E. Muchas personas que durante años han trabajado con la HECV no tienen idea de que esa pequeña válvula interna está ahí. Su función es permitir que la HECV se abra nuevamente después que esta se haya cerrado por completo al concluir el suministro. Puedes comprobar su funcionamiento en la prueba anterior liberando la presión de la manguera después de concluir el ensayo y observando el manómetro colocado en la boquilla de suministro. La válvula E, se abrira cuando la presión de la manguera ha caído a 30 psi aproximadamente, por debajo de la presión de ajuste del resorte.

Casi termina el boletín, y aún no hemos mencionado la mejor prestación que ofrece la HECV: nos referimos al control de picos de presión (golpe de ariete). Estamos en presencia de un dispositivo sencillo que no es mucho más grande que su puño. Tiene solo una parte móvil y no tiene controles externos, el cual está montado en la boquilla de abastecimiento de combustible donde detecta instantáneamente que la válvula interna de la aeronave se ha cerrado. Al ocurrir eso la HECV simplemente se cierra ¡muy rápido! evitando la propagación de la onda de presión. En el gran número de ensayos que he presenciado con la HECV, el aumento del pico de presión en la aeronave nunca ha superado los 90 psi. La mayoría de las especificaciones permiten 120 psi como máximo. Desafortunadamente, no puede medir un aumento del pico de presión con manómetros comunes, porque el mecanismo de los mismos no responde con la rapidez necesaria. Puede pensar que su manómetro muestra el aumento, pero no es así. La única forma en que se puede medir un aumento de presión es con un transductor o transmisor de presión que tenga una respuesta de alta frecuencia y mida la presión en corto espacio de tiempo. Este aumento se rastrea en un registro. Un fallo de la válvula en línea o de la válvula del hidrante puede ocurrir en sistemas modernos que tienen clasificaciones de 275 psi, pero con un HECV que pesa solo 2.3 lbs, puede proteger a la aeronave con efectividad. ¡Qué dispositivo tan fantástico!

GamGram 33: Hose End Pressure Control Valves

Keeping the barnyard gate closed is the surest way to keep a horse from getting away. Think of a Hose End pressure Control Valve (HECV) as the “gate”. You could tether the horse to a stake with a rope, but if the rope fails, the horse leaves through the open gate. Think of the “rope” as the on-board pressure control valve of the refueling vehicle. The majority of equipment specifications today require that there be two separate fueling pressure controls; one backs up the other in case of a failure. The gate plus the rope gives better odds! The HECV valve is clearly the least expensive of all pressure control devices on the market and has become very popular as a second control.

The HECV came into use in the 1960’s when fueling rates were increasing and the industry recognized that it had really not paid enough attention to pressure control, and in particular, prevention of pressure surges at the aircraft. The first product on the market was a massive fueling nozzle having an integral pressure control device. This rather complex device gave way shortly to the relatively simple HECV that we know today. There are at least four versions available today; we will restrict this essay to the most popular variety which is made by Carter Ground Fueling, division of Argo-Tech and Whittaker, division of Meggitt.

Before we describe how they work, there is one thing we must get straight. If you want to measure something (length, pressure, weight, light, etc.), you must have a reasonable starting point, a “base-line”, a datum. You would not measure your height by starting with your nose! If you want to measure a pressure in a fuel system, the only logical starting point or datum is atmospheric pressure. If an oil pressure gauge on an engine reads 100 psi, that means 100 psi above atmospheric pressure.

In a fuel system, we must use atmospheric pressure as our “base” or datum. If a HECV valve is supposed to control at 45 psi, it must be 45 psi above atmospheric pressure. But, how does the valve know atmospheric pressure? Obviously, we must tell it — this is done in a HECV with a Vent Port that will duct atmospheric pressure to one side of a piston. See drawing. If fuel pressure is on the other side of the piston, we have “created” a pressure measuring device. By using a spring on the low pressure side, the fuel pressure is measured by how much the spring is compressed.

Now, with the matter of a base-line established, we see in the drawing that the more the Sensing Piston moves in compressing the spring, the smaller is the passageway for fuel to pass through between the lip F and the seal C. The outer ring A which is attached to the Sensing Piston with cross webs, is often called the “outer piston”, but it is clearly not a piston. As there is no proper word, think of it as a “cookie cutter” — it literally shears the fuel stream! It creates a pressure drop. The more it cuts off the fuel flow, the lower the downstream pressure.

Now that the action of the HECV valve is understood, what do you think of an operator who puts a plug in the vent port “because it leaked”? It has really happened! The HECV valve then became inoperative, because it had no way to sense atmospheric pressure. What should have been done was the replacement of the seal B.

Back in the first paragraph, we talked about the horse in the barnyard and how the HECV could be thought of as the gate. Then we said that a tether rope could be considered as the on-board pressure control valve. Periodically, we must check the performance of both valves. It is not very difficult to check the HECV valve, because all you need is a pressure gauge in the side port of the nozzle or on a fitting just downstream.

Think about how you can check the truck’s on-board control valve. This is more difficult because there is no convenient port to mount a pressure gauge. What we must do is simulate a condition of failure of the HECV, and then see if the nozzle pressure would be controlled by the on-board valve alone. A simple way to do this is with a tube having quick disconnects on both ends. It is called a Block-Out Device. All it does is provide you with a way to temporarily put fuel pressure at the Vent Port to keep the piston from sensing atmospheric pressure. With fuel pressure on both sides of the piston, the HECV is prevented from operating. Unfortunately, this simple test method creates an aggravation — it makes the normally dry vent port be wet with fuel. So after this test, it is a good idea to cycle the HECV several times to blow fuel out from behind the piston; this avoids false reports that the HECV is leaking.

In recent years, the manufacturers have devised block out devices that mechanically interfere with motion of the piston. No tubes are needed and there is no wetting of the vent port.

Which brings us to the question of how to determine if the spring has lost some of its force or if any of the seals in the HECV need replacement. Clearly, if seal B leaks, we can easily see fuel leaking from the vent port. But how do you test seals C and D? This requires a pressure gauge in the side port of the nozzle – or in the downstream piping of a test stand. The best way to run these tests is with a piston-type hand pump, because it allows you to increase pressure very slowly. A hose tester serves this purpose, but only if you connect it upstream of the HECV and downstream of the on-board control valve on the vehicle. As you pump, the hose tester pressure gauge and the nozzle pressure will be very nearly the same until the outer piston reaches seal C. If seals C, D, and E do no leak, the pressure in the nozzle should hold at the pressure rating of the spring as you increase the hose tester pressure to 100 or 200 psi. If the nozzle pressure holds at a level more than 3 psi different from the spring setting, you may need a new spring.

Here is where we learn about the pressure relief valve E. Many people who have worked with HECV’s for years have no idea it is there. What it does is allow the HECV to open again after it has closed. You can check its action in the above test by releasing hose pressure after the test and watching the nozzle pressure gauge. The relief will usually pop open when hose pressure has dropped to about 30 psi below the spring setting.

Now we are at the end of the page, and we still have not mentioned the very best feature of the HECV — pressure surge control. Here is a simple device, not much larger than your fist. It has one moving part and no external controls. You mount it on the fueling nozzle where it can sense instantly that the internal valve of the aircraft has closed. The HECV simply closes — fast! In test after test that I have witnessed on HECV’s, the surge at the aircraft has never gone above 90 psi. Most specifications permit 120 psi as a maximum. Unfortunately, you cannot measure a surge pressure on an airport with common pressure gauges, because the mechanism will not respond quickly enough. You may think your gauge shows the surge, but it is telling you a lie. The only way a surge pressure can be measured is with a pressure transducer having high frequency response. The surge is then traced on a recorder.

Failure of the on-board valve or of the hydrant valve may occur in modern systems having ratings of 275 psi, but with a HECV weighing only 2.3 lbs, you can positively protect the aircraft. What a fantastic device!

GamGram 32: La Presión en la Boquilla de Suministro y el Venturi

En casi todos los camiones repostadores de combustible y carros hidrantes destinados al reabastecimiento de la aeronave por debajo del plano (a presión) tienen un panel de control en el que se ubica un manómetro con el rotulo indicador que dice “presión de la boquilla”. Como este no está conectado a la boquilla, ¿cómo es posible medir la presión la presión real en la salida de la misma? ¿Por arte de magia? En efecto no muestra la presión de la boquilla! Lo que señala es una presión simulada igual a la presión de la boquilla de gaseo. El manómetro está conectado a un dispositivo llamado Venturi el casi siempre se monta en la entrada del carrete de manguera. Pocas personas entienden la función del Venturi y cómo ajustarlo correctamente y como consecuencia de eso existe una gran cantidad de los Venturi en el mundo que no están debidamente ajustados.

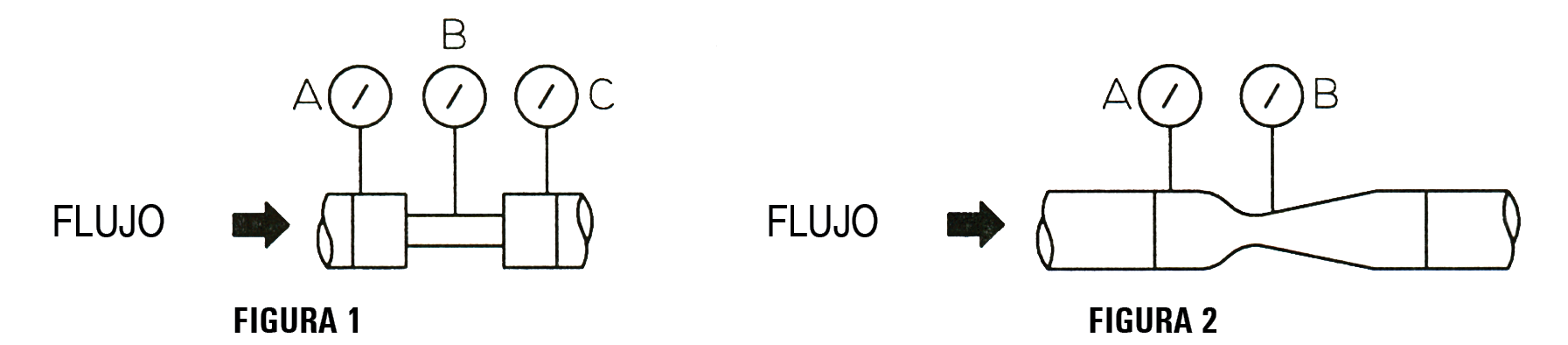

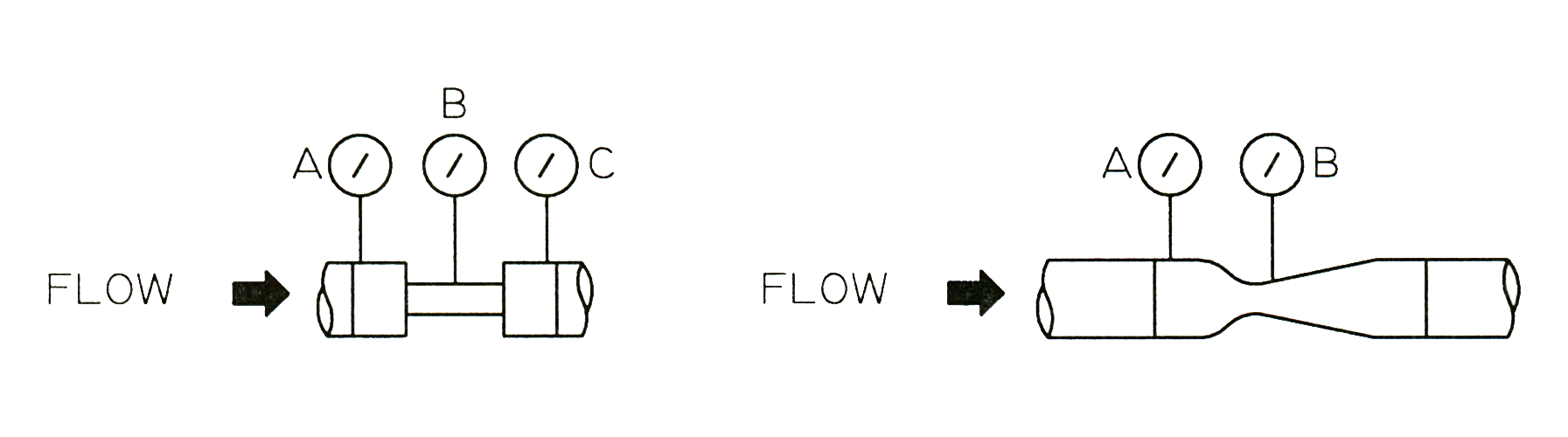

Para entender su funcionamiento hay que entender la dinámica de la energía. En una tubería por donde transita un fluido, la energía en cualquier punto del sistema depende de la velocidad y presión. El nivel de energía permanece constante excepto por algunas disminuciones graduales causadas por la fricción a medida que el fluido pasa a través válvulas, accesorios y a lo largo de la propia tubería. En la figura 1, las presiones en A, B y C serán exactamente las mismas si no hay flujo. Si se produce el flujo, la presión en C será casi la misma que en A, menos la pérdida por fricción. Sin embargo, la presión en B será mucho menor que en C la razón es porque convertimos parte de la energía de presión en energía cinética de velocidad para lograr pasar el fluido a través de la pequeña abertura. Pasada la restricción, la energía de la velocidad disminuye, por lo que la energía de la presión aumenta.

El científico italiano Giovanni Venturi descubrió en un diseño de hace 200 años que podía fabricar un excelente caudalímetro con una caída de presión muy pequeña, el cual presenta una salida muy suave después de la restricción evitando las turbulencias y fricción. (Ver Figura 2). La zona de recuperación de presión es una reducción gradual con un ángulo muy suave hasta alcanzar el tamaño original después de alcanzar diámetro la tubería. La caída de presión (pérdida de energía debido a la fricción) en este diseño es mucho menor que en la figura 1.

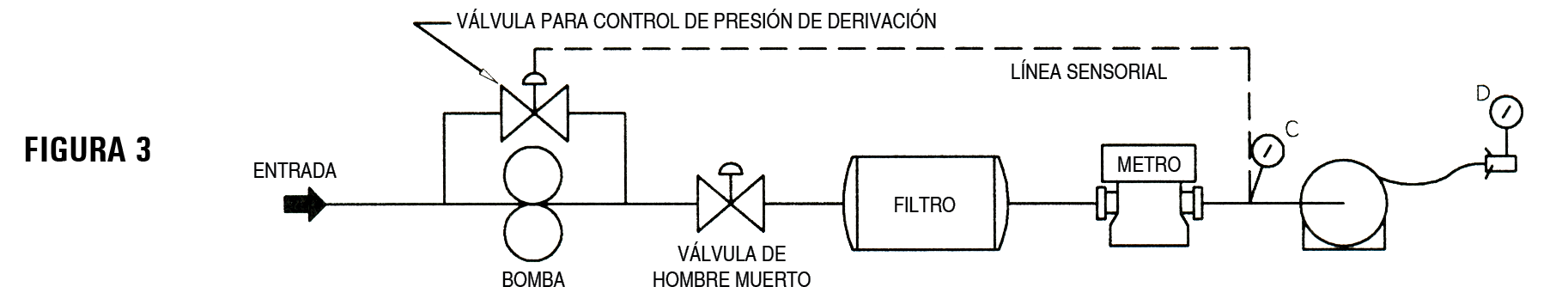

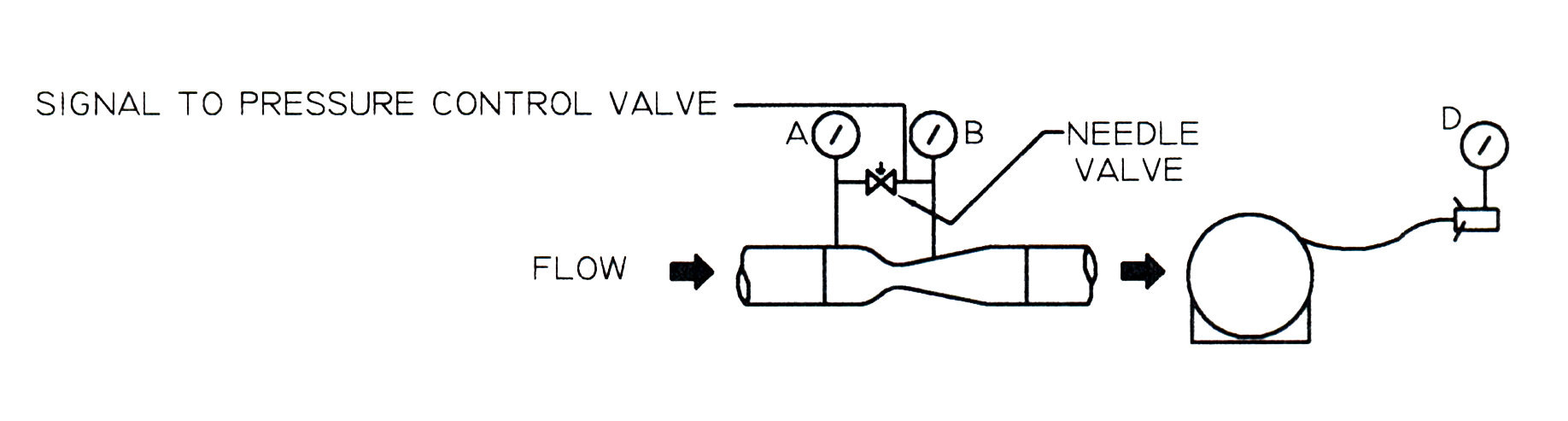

El uso del Venturi en un sistema de combustible de aviación no es precisamente medir el caudal sino proporcionar una simulación de la presión de la boquilla en la sección B y utilizar esa presión como la señal de mando para actuar sobre la válvula de control de presión. Cuando se bombea combustible a una aeronave, se prefiere hacer con el máximo flujo posible, pero la presión debe mantenerse por debajo de 50 psi que es la presión máxima permitida para suministrar combustible a la aeronave de combustible y lograr la tasa de flujo máxima.

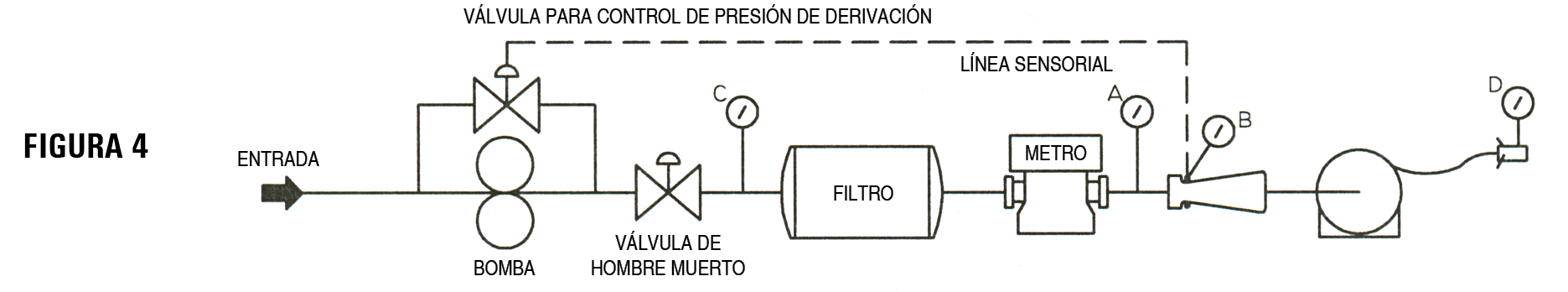

Observe la figura 3: Para que este sistema obtenga 50 psi en la toma de la aeronave, (teniendo en cuenta que la pérdida de presión en el carrete y la manguera es de 30 psi), se requiere una presión de 80 psi en el punto C. El problema es que al llenarse los tanques en la aeronave no hay casi flujo, y por lo tanto, no hay caída de presión. Sin un Venturi en la línea de dicho sistema, pondría 80 psi en la toma de la aeronave causando daños al sistema de combustible de la aeronave. Si se establece en 50 psi, en el punto C para tratar de evitar esos danos entonces la tasa de abastecimiento de combustible real sería muy lenta, y no se acercaría a la tasa de diseño porque la caída de presión entre los puntos C y D consumiría gran parte de esos 50 psi llegando a la aeronave con mucho menos presión. La Figura 3 muestra un sistema simple con válvula de control de presión única sin compensación.

Al colocar un Venturi justo antes del carrete de la manguera como se muestra en la figura 4 se daría solución al problema puesto que la caída la caída de presión a través del filtro y el metro son ignorados por la válvula para control de presión en la toma del avión. La función del Venturi es compensar la caída de presión que ocurre al pasar el combustible por el carrete, la manguera y la boquilla que se conecta a la aeronave. A medida que aumenta el flujo, el Venturi “engaña” a la válvula de control de presión y se obtiene suficiente presión para que haya 50 psi en el punto de baja presión (B), el cual está “sintonizado” para que coincidan B y D. Bajo condiciones de flujo completo, la presión de suministro (C) puede ser incluso de 90 psi y la presión en el punto A, de 70 psi; pero la presión en la boquilla y en el punto B siempre será de 50 psi. Cuando el avión está lleno y el flujo se detiene, la presión A, B, C y D vuelven a 50 psi.

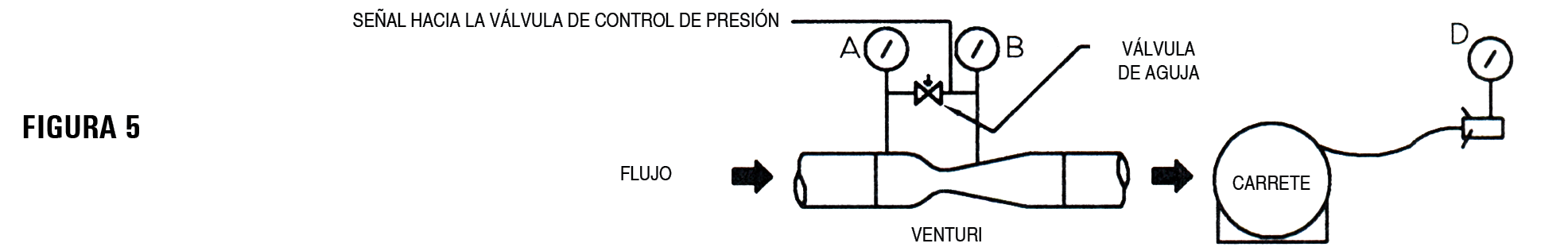

Ajuste del Venturi

Los Venturi utilizados para el combustible de aviación no son elaborados para cada sistema, pues maquinar (tornear) cada Venturi a la medida que se necesita sería demasiado costoso. En cambio, se selecciona uno gustable a un rango amplio de compensación. Por ejemplo, el Whittaker (anteriormente Thiem) F505 proporciona una compensación de hasta 34 psi en depresión, para un flujo de hasta 600 GPM. Si usted en su sistema solo necesita 27 psi de depresión, en atas de compensar la caída de presión a través del carrete de manguera, la manguera y la boquilla, debe “purgar” parte de la señal resultante del Venturi enviada la válvula de regulación de presión. Esto se hace a través del ajuste en la apertura de una válvula de aguja (figura 5) colocada en la línea de combustible de alta presión, a la entrada del Venturi y al abrirla parte del combustible fluirá hacia la zona de baja presión (garganta) del Venturi. La señal de presión “mixta” resultante (27 psi) retroalimenta a la válvula de d e presión como su “comando” para abrir o cerrar. Cuando se ajusta correctamente, las presiones en los manómetros B y D son iguales. Esto debe verificarse bajo dos condiciones: sin flujo (0 caudal) y con el caudal máximo del sistema.

- Cuando el Venturi se ajusta correctamente, el sistema logra el máximo caudal siempre sin ningún peligro para la aeronave. Si varía la resistencia del sistema al cambiar la longitud de la manguera o el diámetro de la misma, así como el tipo o modelo de boquilla se debe reajustar nuevamente el Venturi. Recomendamos que que el ajuste debe ser verificado al menos una vez al mes. De esta manera, se puede detectar un posible problema con el sistema de control de presión y que no se compromete la seguridad del suministro con el flujo máximo.

- Si su equipo de reabastecimiento tiene instalado en la boquilla de suministro un regulador de presión para punta de manguera, conocido como HECV por sus siglas en inglés, al ejecutar el ajuste el Venturi este accesorio debe ser bloqueado o retirado. Después de probar el sistema, retire el dispositivo de bloqueo y compruebe el sistema nuevamente, (al restablecerse la HECV puede que el puerto de ventilación salpique algo de combustible). Tenga en cuenta que si en vez de bloquear la HECV para realizar la calibración usted decide retirarla, una vez colocada nuevamente la caída de presión que esta impone al sistema no será tomada en cuenta en la compensación del Venturi.

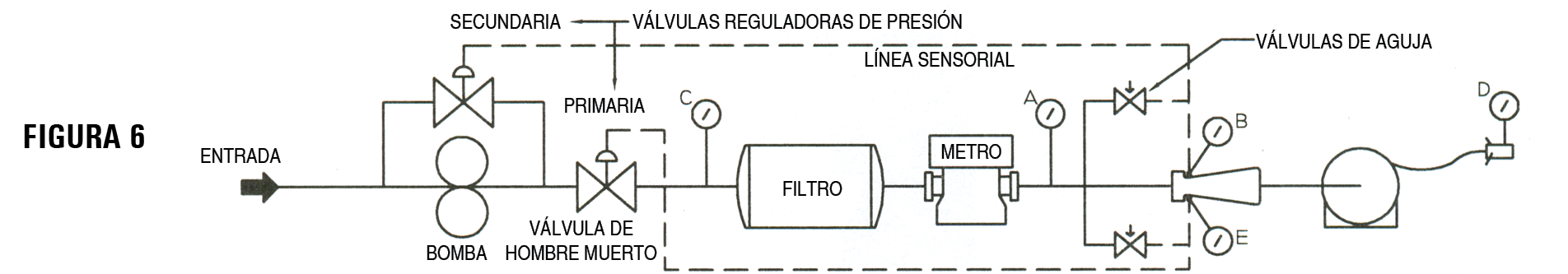

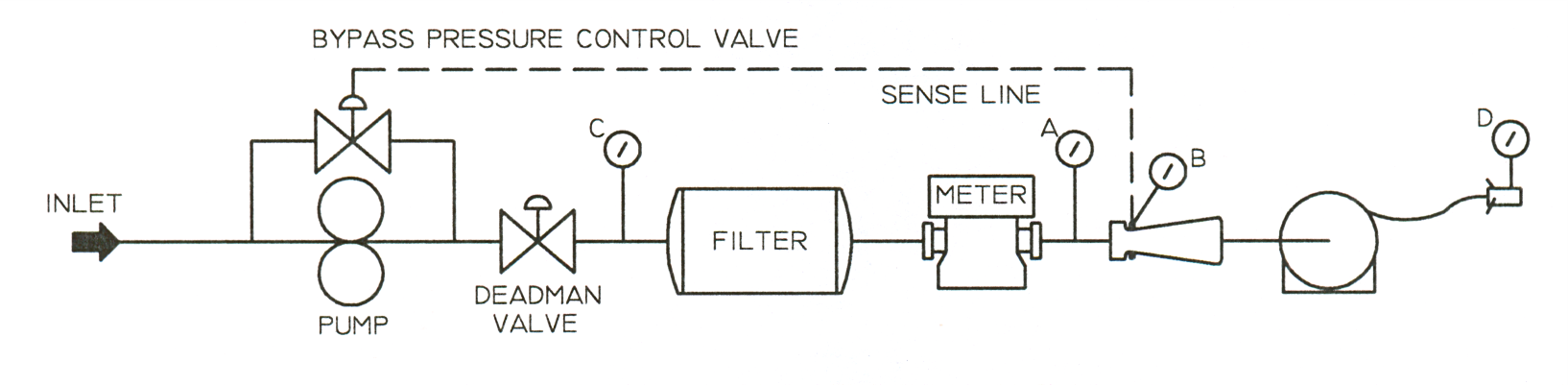

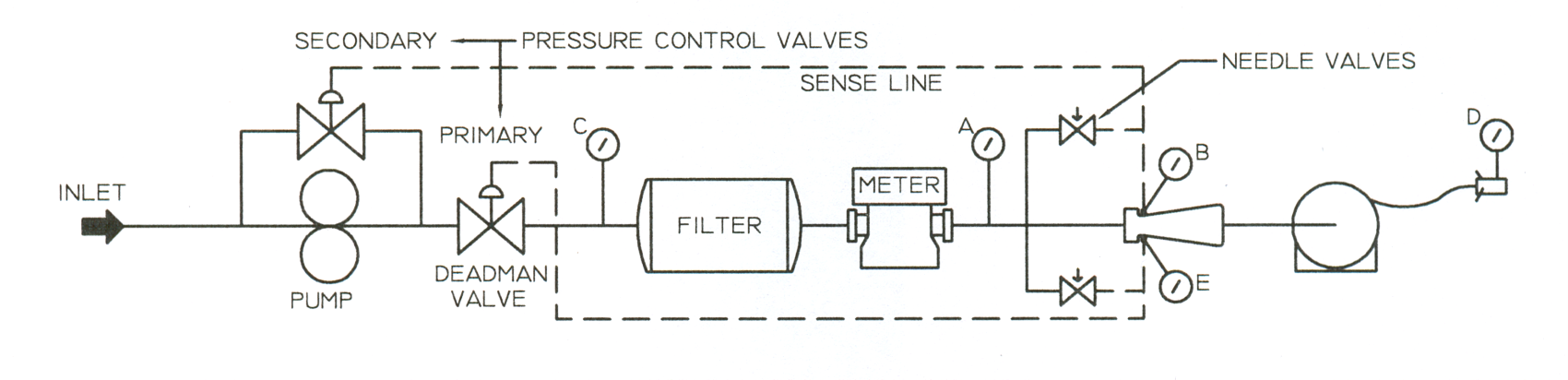

- Por lo general las especificaciones para equipos de abastecimiento de combustible requieren que los controles de presión sean duplicados: Uno primario y otro secundario como reserva o soporte. Esto se logra por combinaciones de los diferentes tipos de controles de presión: control de presión en línea, control de presión con derivación y el control de presión en punta de manguera. (Abordaremos este tema en otro boletín Gamgram). Un método muy común es la combinación de utilizar como controlador primario la válvula de regulación en línea (IPCV), con el sistema de “hombre muerto” (“dispositivo de Presencia”) y como controlador secundario la válvula controladora de presión con derivación (bypass). La figura 6 muestra el procedimiento. Nótese que ambas válvulas reguladoras deben ajustarse para controlar la presión a diferentes magnitudes pues si se ajustan iguales “lucharán” entre sí al tratar de controlar a la vez la presión y como consecuencia la inestabilidad que esto provoca, Cualquier combinación seleccionada, se debe ajustar para que el regulador primario controle la presión de 5 a 15 psi, por debajo de la presión a la que estará ajustado el controlador secundario. Tal objetivo se logra ajustando los reguladores a diferentes presiones, o enviando a los diferentes reguladores señales desde el Venturi, sintonizadas de manera diferente y por separado. El ejemplo de la figura muestra el controlador en línea (primario) configurado a 45 psi, (presión E), el controlador de derivación (secundario) está configurado a 50 psi (presión B),de esta forma si la válvula del avión cierra de pronto , la válvula secundaria respalda a la válvula principal al abrirse rápidamente para aliviar la presión en la válvula principal. (La presión primaria se puede configurar hasta 55 psi).

Muchos sistemas en camiones de reabastecimiento de combustible utilizan una presión del aire como la presión de referencia de la válvula y es ajustada mediante un regulador de presión de aire. Es una buena práctica usar un regulador con bloqueo o sello (consulte el Boletín 70) para evitar ajustes no autorizados o “accidentales”. Para la válvula reguladora de Whittaker, la presión de referencia del aire, en dependencia del tipo de servo mando, debe ser de 16 o 25 psi, mayor que la presión deseada para la regulación del combustible. Esta diferencia se denomina presión de sesgo o de desviación (bias). El propósito de esta presión adicional es que el servo controlador trabaje de forma más fluida, suave y logre un mejor funcionamiento.

Para comprender mejor como funciona este sistema, analícelo de esta manera: la presión de referencia del aire se aplica en un lado de un pistón piloto de detección; la presión del Venturi estará del otro lado con la adición de la fuerza de un resorte que proporciona la presión de sesgo. Si la fuerza resultante (la suma de la de la fuerza del resorte más la presión del Venturi) es mayor que la presión de aire de referencia, el pistón se desplazará ligeramente hacia el lado del aire; esto hace que la válvula de control de presión se cierre aguas abajo y hacer que el pistón piloto regrese a una posición de equilibrio nuevamente.

GamGram 32: Venturi and Nozzle Pressure

On nearly every refueler truck and hydrant cart which is capable of underwing (pressure) refueling there is a gauge marked “nozzle pressure”. Since it is not connected to the nozzle, how can it really show actual nozzle pressure? There is no magic involved. Actually, it does not show nozzle pressure! What it shows is simulated nozzle pressure. The gauge is connected to a device called a VENTURI. It is usually mounted at the inlet of the hose reel. Few people understand what the venturi does or how to adjust it properly. A large number of the venturis in the world are not properly adjusted.

To understand a venturi, we have to understand energy. In a flowing pipe, the energy at any point depends on velocity and pressure. The energy level remains the same except for gradual decreases caused by friction as the fluid passes through valves, fittings and pipe. In Figure 1, the pressures at A, B and C will be exactly the same if there is no flow. If flow takes place, the pressure at C will be nearly the same as at A, less a friction loss. However, the pressure at B will be much lower than at C. The reason is that we turned some of the pressure energy into velocity energy to get the fluid through the small opening. After the restriction, the velocity energy decreases so the pressure energy must increase accordingly.

Giovanni Venturi, the Italian scientist, discovered 200 years ago that he could make an excellent flow meter with very little pressure loss if he carefully designed the outlet after the restriction to avoid turbulence and friction. See Figure 2. The pressure recovery zone is a long gradual taper back to the original pipe size. The pressure drop (energy loss due to friction) in his design is much less than in Figure 1.

FIGURE 1

FIGURE 2

The purpose of a venturi in a fuel system is not to measure flow rate but to provide a simulation of nozzle pressure at B and to use that pressure as the control signal for the pressure control valve. When fuel is pumped to an aircraft, you want maximum flow, but pressure must be kept below 50 psi maximum aircraft fueling pressure to achieve maximum flow rate into the aircraft. See Figure 3. Such a system may require 80 psi at point C in order to result in 50 psi at the aircraft (D), assuming a 30 psi pressure drop in the reel and hose. The problem is that when the aircraft is full, there is no flow and therefore no pressure drop. Without a venturi such a system would, at no flow, put 80 psi on the aircraft. This could cause damage to the aircraft fuel system. If set at 50 psi, the actual fueling rate would be very slow, no where near the design rate because the pressure drop between points C and D would use up much of that 50 psi.

FIGURE 3

(The above example shows a simple, non-compensated single pressure control valve system, for simplicity.)

The venturi system (Figure 4) solves this problem. By locating the venturi just before the hose reel, pressure drop across the filter and meter is ignored by the pressure controller. The venturi’s job is to compensate for pressure drop in the hose reel, hose and nozzle. As flow increases, the venturi “fools” the pressure control valve into delivering enough pressure so that there is 50 psi at the low pressure point (B). The venturi is “tuned” so that B and D match. Under full flow conditions, supply pressure (C) may be 90 psi and pressure at point A may be 70 psi, but pressure at the nozzle and at point B is 50 psi. When the aircraft is full and flow stops, pressure A, B, C and D return to 50 psi.

FIGURE 4

Adjustment of the Venturi

Venturis are not designed to match each system because it would be far too expensive to custom machine each one. Instead, a venturi is selected that has too much compensation. The Whittaker (formerly Thiem) F505 provides up to a 34 psi pressure depression at 600 gpm. If you only need 27 psi of depression to compensate for the pressure drop through the hose reel, hose and nozzle, you must “bleed off” some of the signal. This is done by adjusting a needle valve (Figure 5) so that some fuel from the high pressure zone at the venturi inlet will flow to the venturi throat. The resulting “mixed” pressure signal (27 psi below system pressure) is then fed back to the control valve as its “command”. When correctly adjusted, the pressures at gauges B and D read the same. This should be checked at no flow and at full system flow rate.

FIGURE 5

- When properly adjusted, the system allows maximum flow rate without danger to the aircraft. If you change to a different hose length or size (diameter), the venturi must be re-adjusted. We recommend that this adjustment be checked at least once a month. In this way, a possible problem with the pressure control system may be detected and maximum safe flow rate is assured.

- If a hose-end pressure control valve (HECV) is mounted on the nozzle, it must be either removed or “blocked out” to adjust the venturi “nozzle pressure”. When finished testing the system, remove the block-out device and re-test the system. (The HECV vent will spray some fuel when next used!) Bear in mind that if the HECV is removed for this test, its own pressure drop will not be compensated for by the venturi.

- Most specifications for fueling equipment now require dual pressure controls, one primary and one secondary or “back up”. This can be achieved by various combinations of inline, bypass and hose-end controls. (We will address this subject in a future Gamgram). A common method has the deadman valve serve as a primary pressure controller with the bypass valve as a secondary controller. Figure 6 shows how this is done. Both valves must not be adjusted to control the same pressure because they will “fight” one another with resulting instability. In any system, the primary regulator controls pressure 5 to 15 psi lower than the secondary. This may be done either by setting the regulators at different pressures, or by sending the regulators differently tuned venturi signals. In this example, the in-line (primary) controller is set at 45 psi, (pressure E). The bypass (secondary) controller is set at 50 psi (pressure B). With this arrangement, if the aircraft valve closes suddenly, the secondary valve backs up the primary valve by opening quickly to relieve pressure on the primary. (Primary pressure may be set as high as 55 psi).

FIGURE 6

Many systems on refueling trucks use air pressure as a reference using an air pressure regulator. It is a good idea to use a locking regulator (See Bulletin 70) to prevent unauthorized or “accidental” adjustment. On a Whittaker regulator, this will be 16 or 25 psi higher than the desired fuel pressure. This difference is called the “bias” pressure. The purpose of this bias pressure is to allow smooth operation of the controller. To better understand this system, think of it this way: The air reference pressure is on one side of a sensing pilot piston with the venturi pressure on the other side with a bias spring. If the total of spring force and venturi pressure is greater than the air reference pressure, the piston moves slightly toward the air side; this results in the control valve closing slightly to reduce system pressure and make the sensing piston return to a balanced position.

GamGram 31: Tuberías, Roscas, y Tubos (Piping)

Este GamGram es resultado de una frustración. Al parecer es necesario que una persona trabaje con tubos (piping), tuberías y roscas por lo menos un periodo de 5 años, antes que la persona conozca y entendía sus características, y entonces, durante ese periodo de aprendizaje la mayoría de las veces se ordena conexiones y tuberías de tamaño incorrecto.

Cliente: “Ordené 10 válvulas de 3/8 de una pulgada, y usted me envió estas cosas grandes con roscas de tuberías que son de casi ¾ de una pulgada de diámetro”.

Repuesta: “Sí, los tubos de 3/8 de una pulgada tienen un diámetro externo de aproximadamente ¾ de pulgada, 75 pulgadas menos. Te enviamos lo que pediste.

Cliente: “Pero medí la tubería y tenía aproximadamente 3/8 de una pulgada de diámetro externo. ¿Cómo puede decirme que esta tubería de ¾ de pulgada es la que pedí?”

Repuesta: “Si nos hubiera dicho la medida de la tubería, le habríamos mandado válvulas de 1/8 de pulgada. Los tubos de 1/8 de pulgada tienen un diámetro externo de 0.03 pulgadas más grande que 3/8 de pulgada”.

Cliente: ¡Dios, ustedes están locos!

El cliente se sintió frustrado y se molestó, nosotros también. Veamos que sucede con los tamaños y medidas de las tuberías de tubos. No pretendemos pretendemos justificar las peculiaridades del sistema, solo trataremos d de explicarlo.

En sus inicios, las tuberías fueron hechas mediante el proceso de fundición. El diámetro interior, medía 3/8 de pulgada, 1, 3 pulgadas u otro tamaño deseado Durante los pasados 120 años, se perfeccionó la fabricación de tuberías con el método de la forja (tuberías forjadas), y se encontró innecesario usar las paredes tan gruesas como las que se requerían con la fundición para evitar problemas de las tuberías. Los materiales forjados como el acero y el latón soportan presiones mucho más grandes que las tuberías fundidas. Por supuesto, el grosor de la pared tenía se reducía para ahorrar metal y se abarata el costo; pero la pregunta que surge era si se debía reducir el diámetro externo (O.D.) o aumentar el diámetro interno (I.D.). Alguien decidió que el diámetro interno debería incrementarse, de esta manera, los tubos forjados se conectaban a las mismas conexiones hechas para tubos fundidos. Todo esto trajo la confusión de este mundo en relación a los tamaños de las tuberías.

La siguiente tabla muestra los tamaños de algunas tuberías de Cédula 40 .No aparecen las tolerancias de fabricación. Los números de cédula menores de 40, o mayores de 40, tienen todos el mismo OD; solo cambia el ID. La tubería hecha para alta presión tiene una pared más gruesa, y el número de cédula es mayor que 40, como 80, 120 o 160; la tubería de trabajo ligero tiene paredes más gruesas y menor como 20, 10 o 5.

| Medidas Tubería (pulgadas) |

Medidas Rosca (pulgadas) |

O.D. | I.D. | ||

|---|---|---|---|---|---|

| Pulgadas | MM | Pulgadas | MM | ||

| 1/8 | 27 | 0.405 | 10.3 | 0.269 | 6.8 |

| 1/4 | 18 | 0.540 | 13.7 | 0.364 | 9.3 |

| 3/8 | 18 | 0.675 | 17.2 | 0.493 | 12.5 |

| 1/2 | 14 | 0.840 | 21.3 | 0.622 | 15.8 |

| 3/4 | 14 | 1.050 | 26.7 | 0.824 | 20.9 |

| 1 | 11 1/2 | 1.315 | 33.4 | 1.049 | 26.6 |

| 1 1/4 | 11 1/2 | 1.660 | 42.2 | 1.380 | 35.1 |

| 1 1/2 | 11 1/2 | 1.900 | 48.3 | 1.610 | 40.9 |

| 2 | 11 1/2 | 2.375 | 60.3 | 2.067 | 52.5 |

| 2 1/2 | 8 | 2.875 | 73.0 | 2.469 | 62.7 |

| 3 | 8 | 3.500 | 88.9 | 3.068 | 77.9 |

| 3 1/2 | 8 | 4.000 | 101.6 | 3.548 | 90.1 |

| 4 | 8 | 4.500 | 114.3 | 4.026 | 102.3 |

| 5 | 8 | 5.563 | 141.3 | 5.047 | 128.2 |

| 6 | 8 | 6.625 | 168.3 | 6.065 | 154.1 |

| 8 | 8 | 8.625 | 219.1 | 7.981 | 202.7 |

| 10 | 8 | 10.750 | 273.1 | 10.020 | 254.5 |

| 12 | 8 | 12.750 | 323.9 | 11.938 | 303.2 |

| 14 | 8 | 14.000 | 335.6 | 13.234 | 336.0 |

La lección de todo es que es imposible encontrar una medida en una conexión en un tubo que le diga el tamaño real, hasta que usted alcance la dimensión de 14 pulgadas. El diámetro externo de un tubo de 14 pulgadas es realmente 14 pulgadas; el de 20 pulgadas es 20 pulgadas, etc.

Tubos (tubing)

Estos tubos (tubing), por ejemplo, para equipos de medición, es medida por su diámetro externo, no por su diámetro interno; la tubería de producción de 3/8 de una pulgada mide 3/8 de una pulgada en su diámetro externo, pero su diámetro interno es solamente alrededor de 0.3 pulgadas. Surge el problema con tubos (tubing) en aquellos países, donde se usa el sistema (SI) tamaños métricos; las conexiones norteamericanas de tubos son en fracciones de pulgadas no ajustarán. Por eso es que insistimos que nuestros clientes con el sistema SI tomen las medidas muy exactas; está es la garantía de que proveamos las conexiones de tuberías de producción en medidas métricas correctas.

Las Roscas de las Tuberías

La mayoría de las roscas de tuberías en los servicios de petróleo fuera de Norteamérica son rectas y no son ahusadas (cónicas). Una empaquetadura hace el sellado. Cuando un producto norteamericano llega a un país que usa ese tipo de rosca, el mecánico piensa que la conexión debe ser apretada hasta que no se puedan ver hilos de la rosca en la tubería. El resultado es usualmente que la conexión se raja debido a las tremendas fuerzas que se generan cuando las partes ahusadas son accionadas juntas. Lamentablemente, no hay un momento torsional (torque) determinado para su uso .En términos generales, de 4 a 7 vueltas hace que una unión roscada esté lo suficientemente apretada para evitar salidero si se usa un sellador de rosca (cinta de teflón). Nuestra experiencia nos dice que la mayoría de los fabricantes de conexiones en acero inoxidable no siguen los patrones que especifican que lo apretado de mano se alcanza en 4-5 vueltas. Usted es afortunado si puede tener dos revoluciones.

Cuando los accesorios de acero inoxidable se enroscan en tuberías de aluminio fundido usando cintas de teflón ‘se puede presentar un problema excepcionalmente grave Aunque el teflón proporciona algo de lubricación, no es consistente. Si un hilo de rosca es áspero, en un punto determinado el teflón se rompe y aumenta la fricción; el mecánico siente la resistencia y cree que la junta está apretada sin embargo habrá salidero. Hemos aprendido a lo largo de los años que agregar gel (vaselina) a la cinta después de puesta (antes de enroscar), hace “toda la diferencia del mundo”. Pero te avisamos: la friccion será muy baja puede resultar fácilmente en una conexión un poco más que el apretado a mano hará una conexión a prueba de fugas.

Roscas Tuberías Inglesa Británicas

Aunque las roscas de tubo cónicas británicas se usan en las industrias de países fuera de Norteamérica, la industria petrolera en todas las áreas fuera de Norteamérica parece haberse estandarizado en la rosca inglesa de tubo paralela o recta. Una empaquetadura es la que hace el sellando (estanqueidad). Nos referimos a la rosca conocida como BSPP-Roscas de tubo Británicas Paralelas Estándar. Nos critican por agregar la segunda P. y lo hacemos porque BSP significa “roscas inglesas” la última letra significa paralela (P) o roscas cónicas (T) (Taper).

| Tubería (pulgadas) |

Rosca (pulgadas) |

OD | |

|---|---|---|---|

| Pulgadas | MM | ||

| 1/8 | 28 | 0.383 | 9.7 |

| 1/4 | 19 | 0.518 | 13.2 |

| 3/8 | 19 | 0.656 | 16.7 |

| 1/2 | 14 | 0.825 | 21.0 |

| 3/4 | 14 | 1.041 | 26.4 |

| 1 | 11 | 1.309 | 33.3 |

| 1 1/4 | 11 | 1.650 | 41.9 |

| 1 1/2 | 11 | 1.882 | 47.8 |

| 2 | 11 | 2.347 | 59.6 |

Las roscas NPT se diferencian de las BSP en el ángulo del diente, es de 60 grados en lugar de 55, y las aristas son más pronunciadas. Otra diferencia es en el paso: las roscas NPT tienen 11,5 hilos por pulgada mientras que las BSP tienen 11 hilos por pulgada. Y que la rosca cónica es solo en el macho, no en ambas como la NPT.

Resumen

El método ileso para saber qué Ud. está haciendo al ordenar conexiones de tubos es medir con un calibrador o un micrómetro. Molesta embarcar partes a lugares lejanos y luego saber que el cliente ordenó las partes incorrectas.

GamGram 31: Pipe, Pipe Threads, and Tubing

This issue of the GamGram is written out of total frustration. The problem is that it seems necessary for a person to work with tubing, pipe & pipe threads for at least 5 years before understanding them, and then he orders the wrong size fitting half the time.

Customer: “I ordered ten (10) 3/8 inch toggle valves, and you sent me these big things with threads that are almost 3/4 inch in diameter”.

Answer: “Well, 3/8 inch pipe has an OD that is about 3/4 inch — only 0.075 inches less, so we sent you what you ordered.”

Customer: “But I measured my pipe and it was about 3/8 inches OD. How can you say that your 3/4 inch is what I ordered.”

Answer: “If you had told us what your pipe measured, we would have sent you 1/8 inch valves. Pipe that 1/8 inch size has an OD just 0.03 inches greater than 3/8 inch.”

Customer: “You guys are nuts!”

The customer is frustrated, and so are we. So now we are going to tell you the “facts of life” about pipe sizes. We do not want to appear to justify the peculiarities of the system – all we will do is explain it.

Pipe was originally made by casting processes. The inside diameter measured 3/8 inch or 1 inch or 3 inch, whatever the size was supposed to be. Within the last 120 years, wrought pipe was perfected, but it was found unnecessary to use the heavy wall thicknesses that were required to avoid problems of cast pipe. Wrought materials such as steel and brass could withstand far greater pressures than cast pipe. Obviously, the wall thickness had to be reduced to save metal, but the question was whether the OD should be reduced or the ID increased. Someone decided that the ID should be increased. This way, the wrought pipe could be connected to the same fittings that had been made for cast pipe. This is how the world became confused about pipe sizes.

The following chart gives the sizes of standard schedule 40 pipe. Manufacturing tolerances are not shown. Schedule numbers that are less than 40 or greater than 40 all have the same OD; only the ID changes. Pipe that is made for high pressure has a thicker wall, and the schedule number is greater than 40, such as 80, 120 or 160. Light duty pipe has thicker walls and smaller schedule numbers, such as 20, 10, or 5.

| Pipe Size (inch) | Threads (inch) | Outside Diameter | Inside Diameter | ||

|---|---|---|---|---|---|

| Inch | MM | Inch | MM | ||

| 1/8 | 27 | 0.405 | 10.3 | 0.269 | 6.8 |

| 1/4 | 18 | 0.540 | 13.7 | 0.364 | 9.3 |

| 3/8 | 18 | 0.675 | 17.2 | 0.493 | 12.5 |

| 1/2 | 14 | 0.840 | 21.3 | 0.622 | 15.8 |

| 3/4 | 14 | 1.050 | 26.7 | 0.824 | 20.9 |

| 1 | 11 1/2 | 1.315 | 33.4 | 1.049 | 26.6 |

| 1 1/4 | 11 1/2 | 1.660 | 42.2 | 1.380 | 35.1 |

| 1 1/2 | 11 1/2 | 1.900 | 48.3 | 1.610 | 40.9 |

| 2 | 11 1/2 | 2.375 | 60.3 | 2.067 | 52.5 |

| 2 1/2 | 8 | 2.875 | 73.0 | 2.469 | 62.7 |

| 3 | 8 | 3.500 | 88.9 | 3.068 | 77.9 |

| 3 1/2 | 8 | 4.000 | 101.6 | 3.548 | 90.1 |

| 4 | 8 | 4.500 | 114.3 | 4.026 | 102.3 |

| 5 | 8 | 5.563 | 141.3 | 5.047 | 128.2 |

| 6 | 8 | 6.625 | 168.3 | 6.065 | 154.1 |

| 8 | 8 | 8.625 | 219.1 | 7.981 | 202.7 |

| 10 | 8 | 10.750 | 273.1 | 10.020 | 254.5 |

| 12 | 8 | 12.750 | 323.9 | 11.938 | 303.2 |

| 14 | 8 | 14.000 | 335.6 | 13.234 | 336.0 |

The lesson to learn is that it is impossible to find a dimension on a fitting or a pipe that tells you the actual size until you get up to 14 inch pipe. The OD of 14 inch pipe is really 14 inches; the OD of 20 inch pipe is 20 inches, etc.

So now if all of our good customers would please measure their pipe or pipe fittings, our problem will be solved forever — but we don’t really believe that. Why? Because then we develop confusion about tubing sizes.

Tubing

Tubing is measured by its OD not its ID; 3/8 inch tubing really measures 3/8 inch on its OD, but its ID is usually only about 0.3. Where we have a tubing problem is overseas where metric sizes are used; American fractional inch tubing fittings will not fit. That is why we have to insist that our overseas customers actually take very close measurements. This will insure that we provide the right metric sized tubing fitting.

Pipe Threads

Most pipe threads in petroleum service outside of North America are straight, not tapered. A gasket does the sealing. When an American product reaches an overseas destination, the mechanic thinks that the fitting should be tightened until no threads can be seen on the pipe. The result is usually that the fitting splits open because of the tremendous forces that are created when two tapered parts are driven together. Regrettably, there is no standard torque that should be used. Generally speaking, from 4 to 7 turns will produce a tight joint if a thread sealant, such as Teflon tape, is used. Our experience shows that most manufacturers of stainless steel fittings do not adhere to the standards which specify that hand tightness is reached in 4 – 5 turns. You are lucky to have 2 turns. The number of turns after hand tightening should be 2 or 3.

An exceptionally severe problem develops when stainless steel fittings are screwed into aluminum castings with Teflon tape as the sealant. Although the Teflon provides some lubrication, it is not consistent. If a thread is rough at one point, the Teflon tears away; the mechanic feels the resistance and thinks the joint is tight. It leaks. We have learned over the years that adding petroleum jelly (Vaseline) to the tape after it is applied, makes “all the difference in the world”. But we warn you, the very low friction can easily result in a split fitting. Little more than hand tight will make a leakproof connection.

British Pipe Threads

Although British tapered pipe threads are used in foreign industry, the petroleum industry in all areas out of North America, seem to have standardized on the British parallel or straight pipe thread. A gasket makes the seal. We refer to it as BSPP for British Standard Parallel Pipe threads, but we are criticized for adding the second P. The reason we insist on doing it is because BSP can mean either tapered or parallel threads.

| Pipe Size (inch) | Threads (inch) | Outside Diameter | |

|---|---|---|---|

| Inch | MM | ||

| 1/8 | 28 | 0.383 | 9.7 |

| 1/4 | 19 | 0.518 | 13.2 |

| 3/8 | 19 | 0.656 | 16.7 |

| 1/2 | 14 | 0.825 | 21.0 |

| 3/4 | 14 | 1.041 | 26.4 |

| 1 | 11 | 1.309 | 33.3 |

| 1 1/4 | 11 | 1.650 | 41.9 |

| 1 1/2 | 11 | 1.882 | 47.8 |

| 2 | 11 | 2.347 | 59.6 |

The dimensions of BSPP threads are remarkably close to NPT as the chart shows, but the thread form is 55° instead of 60° and the number of threads per inch is different. Nevertheless, some mechanics consistently make tight connections with Teflon tape when installing NPT male fittings into female BSPP threads if one material is soft, like aluminum.

Summary

The only safe way to know what you are doing when you order pipe fittings is to measure with a caliper or a micrometer. We surely do hate to ship parts half way around the world and then find the customer ordered the wrong size.

NOTE: Just to clarify, OD stands for Outside Diameter, and ID stands for Inside Diameter.

GamGram 30: Operación con los Filtros Separadores en Climas Fríos

Cuando un ingeniero con una base técnica pobre especifica un equipo lo llamamos “ingeniería básica.” Y es una descripción perfecta de la forma en que las personas especifican los calentadores para los filtros separadores de filtro. Llámelo intuición, conjeturas, “abracadabra pata de cabra” o pura charlatanería; porque no existe una base técnica aparente para la forma en que la mayoría de los sistemas de calentadores están diseñados para filtros separadores

Se sabe que los vendedores de filtros separadores hacen declaraciones tan necias como como “un calentador mantiene caliente el filtro separador”. Le recomendamos que aparte bien lejos a ese individuo porque simplemente no sabe lo que está hablando. Piense si su filtro separador opera a un caudal de 600 gpm y el combustible entrante es a 20 °F (-6,7 °C), la cantidad de calor necesaria para elevar la temperatura a 32 °F (0 °C) es de 24 000 BTU/min. Se requiere una entrada de calor de 421 KW pero incluso si ignora por completo la pérdida de calor es altísima de la superficie del recipiente en contacto con la atmósfera, puede ver fácilmente que el calentador típico para un sumidero es clasificado en 1 KW para nada lograra calentar esa carcasa; es como si quisiera derretir el acero con una cerilla!

Los filtros separadores al operar en climas fríos presentan dos problemas diferentes

- Que se congelen las facilidades para el drenaje (accesorios, válvulas, tubería) pues esto impediría drenarlo. (¿Cómo cambia los elementos filtrantes si no puedes evacuar el combustible de la carcasa?).

- Mantener el flujo de combustible a través de elementos sin que estos se bloqueen con el hielo.

El primer problema es el más común. El segundo problema se limita a las regiones donde la temperatura del combustible en los tanques de almacenamiento desciende muy por debajo del punto de congelación del agua.

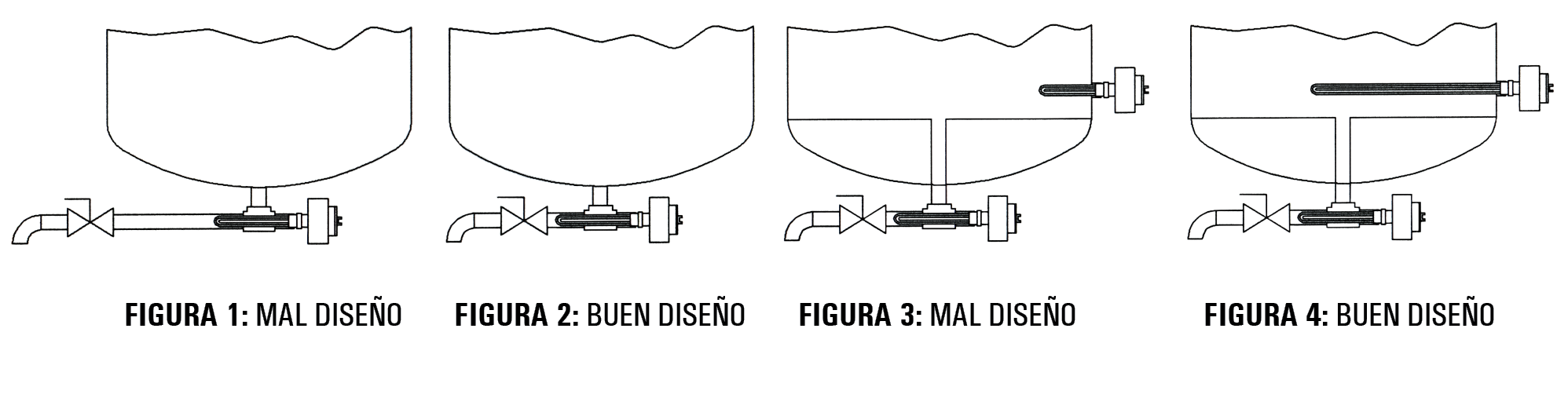

Para mantener los accesorios de drenaje libre de hielo, un calentador de inmersión brinda una respuesta simple, pero toma un tiempo y un análisis cuidadoso para asegurar que el calor se ubicará precisamente ahí donde se necesita. La figura 1 es un ejemplo de miles de instalaciones mal diseñadas. La válvula de drenaje está ubicada para facilitarle al operador el realizar el drenaje, pero la ubicación del calentador no evitará que la válvula se congele. El diseño de la figura 2 es bueno porque la válvula de drenaje está ubicada lo más cerca posible del calentador y este está además directamente debajo de la conexión de drenaje. La recirculación de convención (transporte de energía térmica) a través del desagüe hacia el recipiente tiende a evitar la formación de hielo el cual podría formar un puente sobre la entrada de drenaje en el recipiente. Se ha demostrado que los calentadores de 300 a 750 vatios son adecuados.

Para ayudar al calentador colocado en la línea de drenaje, a menudo se usa un calentador en el sumidero. Sin embargo, muchos de ellos están instalados como en fig. 3. Por supuesto un calentador en tal ubicación en el recipiente no resulta, porque el calor no estará donde se necesite o sea en la entrada del desagüe. En la figura 4, el calentador se presenta de modo que pueda ayudar al drenaje calentando la línea y manteniendo un camino despejado para que el agua salga del recipiente. No hay forma de que se pueda calentar toda la placa de la plataforma, por lo que debe haber hielo en áreas ubicadas lejos de la entrada drenaje. Obviamente, la mayor parte del calor de un calentador de este tipo se elevará hacia arriba, alejándose del agua que se acumula, por lo tanto, es muy importante que el calentador esté ubicado lo más cerca posible de la superficie del sumidero, con suerte no más de ½ pulgada (12 mm) por encima.

Volvamos al primer problema sobre tratar con el hielo que se forma en el combustible antes de que el agua se haya asentado en el pocillo de drenaje. Los tanques de almacenamiento subterráneos casi nunca tienen temperaturas muy bajas, excepto en las regiones del Ártico; sin embargo, la temperatura del combustible contenido en los tanques de almacenamiento aéreos puede caer muy por debajo del punto de congelación del agua en muchas partes del mundo. A medida que la temperatura del combustible desciende por debajo del punto de congelación, el agua disuelta en el combustible se muestra como cristales de hielo, en forma de diminutas agujas microscópicas que no se asientan por ser demasiado pequeñas. Estos fragmentos o hebras de hielo bloquean irremediablemente los elementos coalescentes.

Lidiar con este problema es muy difícil y se dan pocas alternativas. Todas son muy caras, ninguna es simple:

- Utilice aditivos anticongelantes.

- Coloque las carcasas de filtración en el interior de una edificación con calefacción. Cuando los elementos se tapen con hielo, detenga el flujo y espere hasta que el hielo se derrita. Si tiene dinero extra, instale dos sistemas paralelos de filtros para que pueda alternar de uno a otro mientras uno de ellos se descongela.

- Caliente el tanque de almacenamiento de combustible para evitar que se forme hielo.

En caso de que desee conocer algunos otros métodos utilizados en los últimos 40 años, considere los siguientes

- Un fabricante de filtros separadores tenía una unidad especialmente diseñada para ser soterrada; solo la tapa estaría expuesta. ¡La tierra es un gran aislante!

- Se instalaron cientos de filtros separadores dentro de cajas de madera contrachapada que tenían espacio para calentadores eléctrico en el interior. Pero era necesario desmontar la caja para cambiar los elementos.

- Cientos de instalaciones se realizaron con el sumidero y la tubería de drenaje con aislamiento térmico (revestimiento). Pero el agua de lluvia siempre se filtraba en el aislamiento, lo que empeoraba mucho la tarea de calefacción; muchos vasos oxidados en el exterior casi hasta el punto tener de una falla estructural.

Sabemos de dos aeropuertos que se mantuvieron operando en un invierno muy fuerte, aun cuando se le bloqueaban los coalescedores con hielo porque los elementos se retiraban periódicamente y se descongelaban en un edificio con calefacción Así no interrumpieron el abastecimiento de combustible a las aeronaves usando de forma alternativa dos juegos de coalescedores. Como ve no hay soluciones de bajo costo para este problema.

En conclusión, concéntrese en mantener los sistemas de drenaje libres de hielo y luego espere y rece para que no tenga que lidiar con lotes húmedos de combustible.