GamGram 30: Operación con los Filtros Separadores en Climas Fríos

Cuando un ingeniero con una base técnica pobre especifica un equipo lo llamamos “ingeniería básica.” Y es una descripción perfecta de la forma en que las personas especifican los calentadores para los filtros separadores de filtro. Llámelo intuición, conjeturas, “abracadabra pata de cabra” o pura charlatanería; porque no existe una base técnica aparente para la forma en que la mayoría de los sistemas de calentadores están diseñados para filtros separadores

Se sabe que los vendedores de filtros separadores hacen declaraciones tan necias como como “un calentador mantiene caliente el filtro separador”. Le recomendamos que aparte bien lejos a ese individuo porque simplemente no sabe lo que está hablando. Piense si su filtro separador opera a un caudal de 600 gpm y el combustible entrante es a 20 °F (-6,7 °C), la cantidad de calor necesaria para elevar la temperatura a 32 °F (0 °C) es de 24 000 BTU/min. Se requiere una entrada de calor de 421 KW pero incluso si ignora por completo la pérdida de calor es altísima de la superficie del recipiente en contacto con la atmósfera, puede ver fácilmente que el calentador típico para un sumidero es clasificado en 1 KW para nada lograra calentar esa carcasa; es como si quisiera derretir el acero con una cerilla!

Los filtros separadores al operar en climas fríos presentan dos problemas diferentes

- Que se congelen las facilidades para el drenaje (accesorios, válvulas, tubería) pues esto impediría drenarlo. (¿Cómo cambia los elementos filtrantes si no puedes evacuar el combustible de la carcasa?).

- Mantener el flujo de combustible a través de elementos sin que estos se bloqueen con el hielo.

El primer problema es el más común. El segundo problema se limita a las regiones donde la temperatura del combustible en los tanques de almacenamiento desciende muy por debajo del punto de congelación del agua.

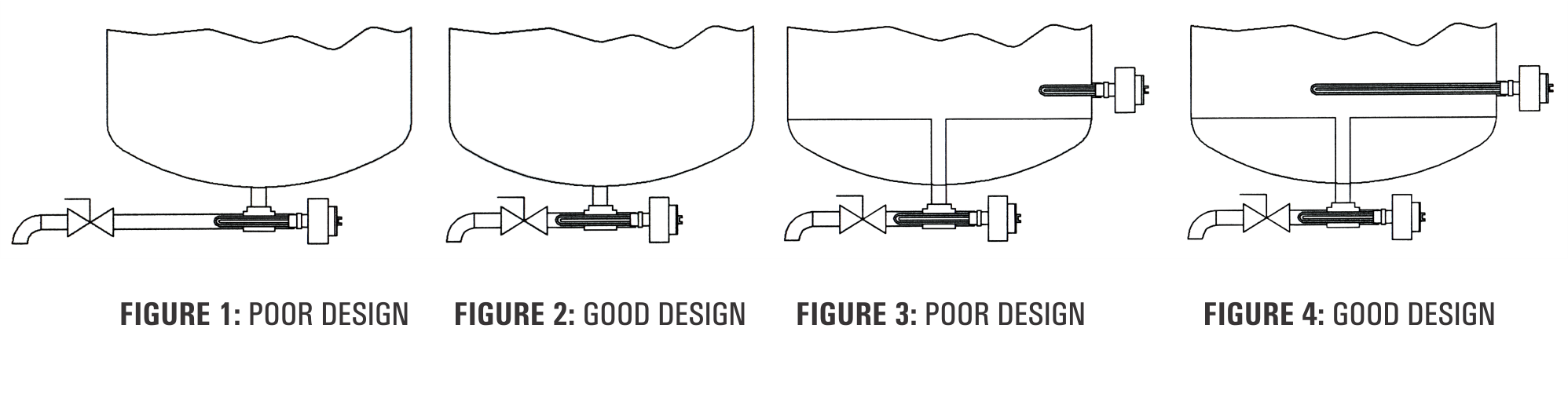

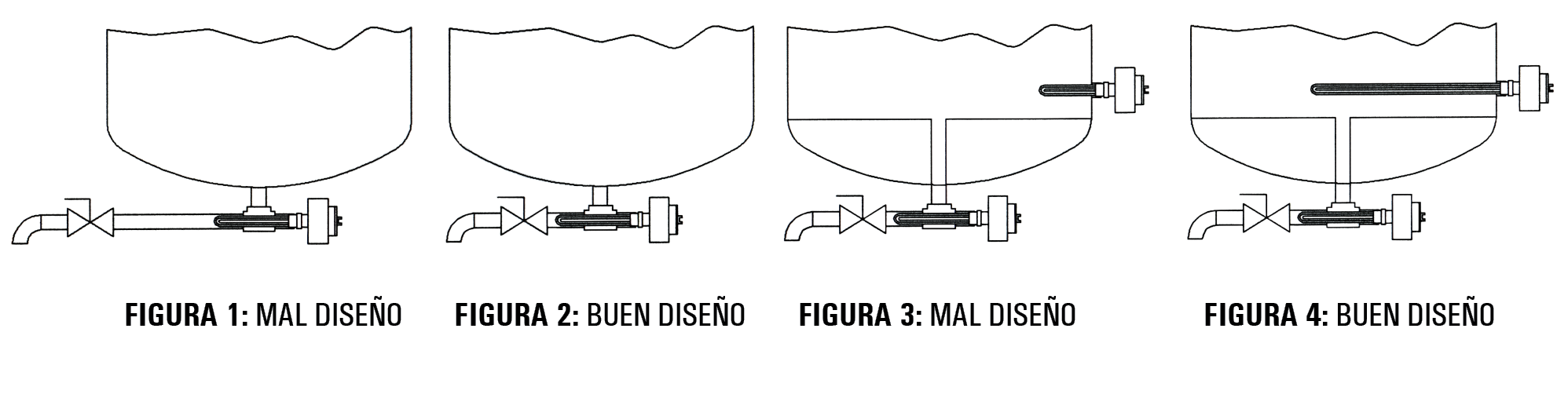

Para mantener los accesorios de drenaje libre de hielo, un calentador de inmersión brinda una respuesta simple, pero toma un tiempo y un análisis cuidadoso para asegurar que el calor se ubicará precisamente ahí donde se necesita. La figura 1 es un ejemplo de miles de instalaciones mal diseñadas. La válvula de drenaje está ubicada para facilitarle al operador el realizar el drenaje, pero la ubicación del calentador no evitará que la válvula se congele. El diseño de la figura 2 es bueno porque la válvula de drenaje está ubicada lo más cerca posible del calentador y este está además directamente debajo de la conexión de drenaje. La recirculación de convención (transporte de energía térmica) a través del desagüe hacia el recipiente tiende a evitar la formación de hielo el cual podría formar un puente sobre la entrada de drenaje en el recipiente. Se ha demostrado que los calentadores de 300 a 750 vatios son adecuados.

Para ayudar al calentador colocado en la línea de drenaje, a menudo se usa un calentador en el sumidero. Sin embargo, muchos de ellos están instalados como en fig. 3. Por supuesto un calentador en tal ubicación en el recipiente no resulta, porque el calor no estará donde se necesite o sea en la entrada del desagüe. En la figura 4, el calentador se presenta de modo que pueda ayudar al drenaje calentando la línea y manteniendo un camino despejado para que el agua salga del recipiente. No hay forma de que se pueda calentar toda la placa de la plataforma, por lo que debe haber hielo en áreas ubicadas lejos de la entrada drenaje. Obviamente, la mayor parte del calor de un calentador de este tipo se elevará hacia arriba, alejándose del agua que se acumula, por lo tanto, es muy importante que el calentador esté ubicado lo más cerca posible de la superficie del sumidero, con suerte no más de ½ pulgada (12 mm) por encima.

Volvamos al primer problema sobre tratar con el hielo que se forma en el combustible antes de que el agua se haya asentado en el pocillo de drenaje. Los tanques de almacenamiento subterráneos casi nunca tienen temperaturas muy bajas, excepto en las regiones del Ártico; sin embargo, la temperatura del combustible contenido en los tanques de almacenamiento aéreos puede caer muy por debajo del punto de congelación del agua en muchas partes del mundo. A medida que la temperatura del combustible desciende por debajo del punto de congelación, el agua disuelta en el combustible se muestra como cristales de hielo, en forma de diminutas agujas microscópicas que no se asientan por ser demasiado pequeñas. Estos fragmentos o hebras de hielo bloquean irremediablemente los elementos coalescentes.

Lidiar con este problema es muy difícil y se dan pocas alternativas. Todas son muy caras, ninguna es simple:

- Utilice aditivos anticongelantes.

- Coloque las carcasas de filtración en el interior de una edificación con calefacción. Cuando los elementos se tapen con hielo, detenga el flujo y espere hasta que el hielo se derrita. Si tiene dinero extra, instale dos sistemas paralelos de filtros para que pueda alternar de uno a otro mientras uno de ellos se descongela.

- Caliente el tanque de almacenamiento de combustible para evitar que se forme hielo.

En caso de que desee conocer algunos otros métodos utilizados en los últimos 40 años, considere los siguientes

- Un fabricante de filtros separadores tenía una unidad especialmente diseñada para ser soterrada; solo la tapa estaría expuesta. ¡La tierra es un gran aislante!

- Se instalaron cientos de filtros separadores dentro de cajas de madera contrachapada que tenían espacio para calentadores eléctrico en el interior. Pero era necesario desmontar la caja para cambiar los elementos.

- Cientos de instalaciones se realizaron con el sumidero y la tubería de drenaje con aislamiento térmico (revestimiento). Pero el agua de lluvia siempre se filtraba en el aislamiento, lo que empeoraba mucho la tarea de calefacción; muchos vasos oxidados en el exterior casi hasta el punto tener de una falla estructural.

Sabemos de dos aeropuertos que se mantuvieron operando en un invierno muy fuerte, aun cuando se le bloqueaban los coalescedores con hielo porque los elementos se retiraban periódicamente y se descongelaban en un edificio con calefacción Así no interrumpieron el abastecimiento de combustible a las aeronaves usando de forma alternativa dos juegos de coalescedores. Como ve no hay soluciones de bajo costo para este problema.

En conclusión, concéntrese en mantener los sistemas de drenaje libres de hielo y luego espere y rece para que no tenga que lidiar con lotes húmedos de combustible.