Bulletin 180: Mini Gammon Gauge

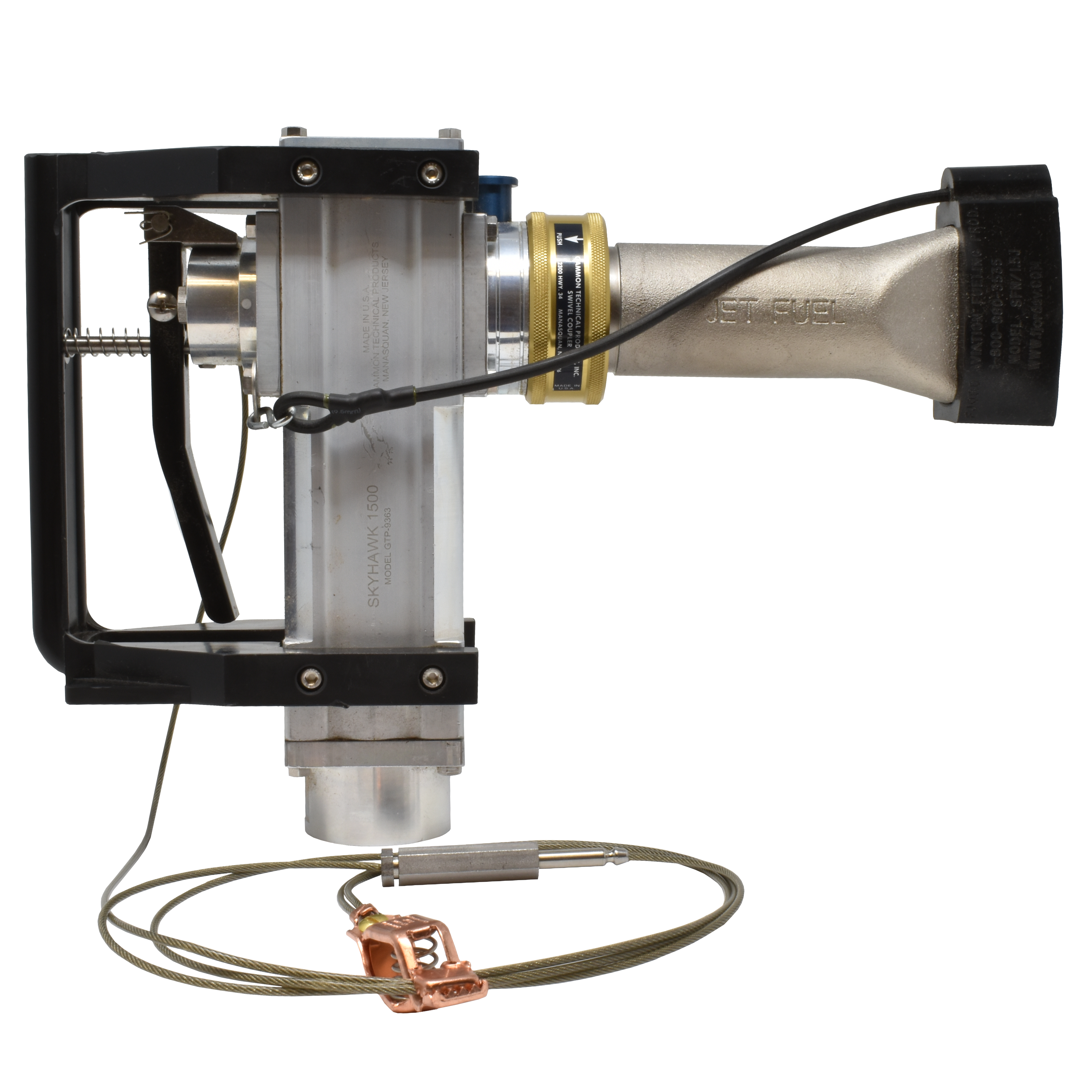

Mini Gammon Gauge Differential Pressure Indicator

The First High-Quality, Inexpensive Direct Reading Differential Pressure Indicator

In 1966, Gammon Technical Products introduced the Gammon Gauge, which quickly became the world’s #1 aviation fuel filter differential pressure gauge. In 2017, we are pleased to introduce the new, patented, smaller gauge, made to the same unparalleled quality standards.

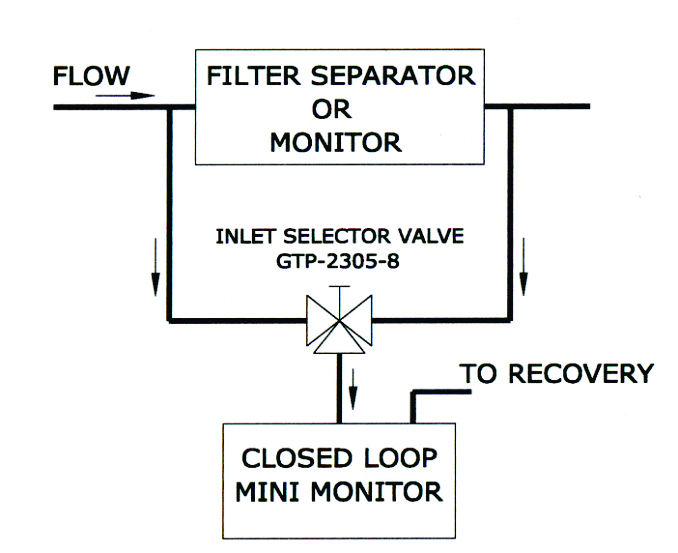

Calibration is simple and does not require a gauge laboratory. Use GTP-2305 or any three-way valve. Our test procedure is accepted by the USAF, Army, Navy, and all major oil companies and airlines in the world as all you need to do to check the accuracy of the Gammon type DP indicator.

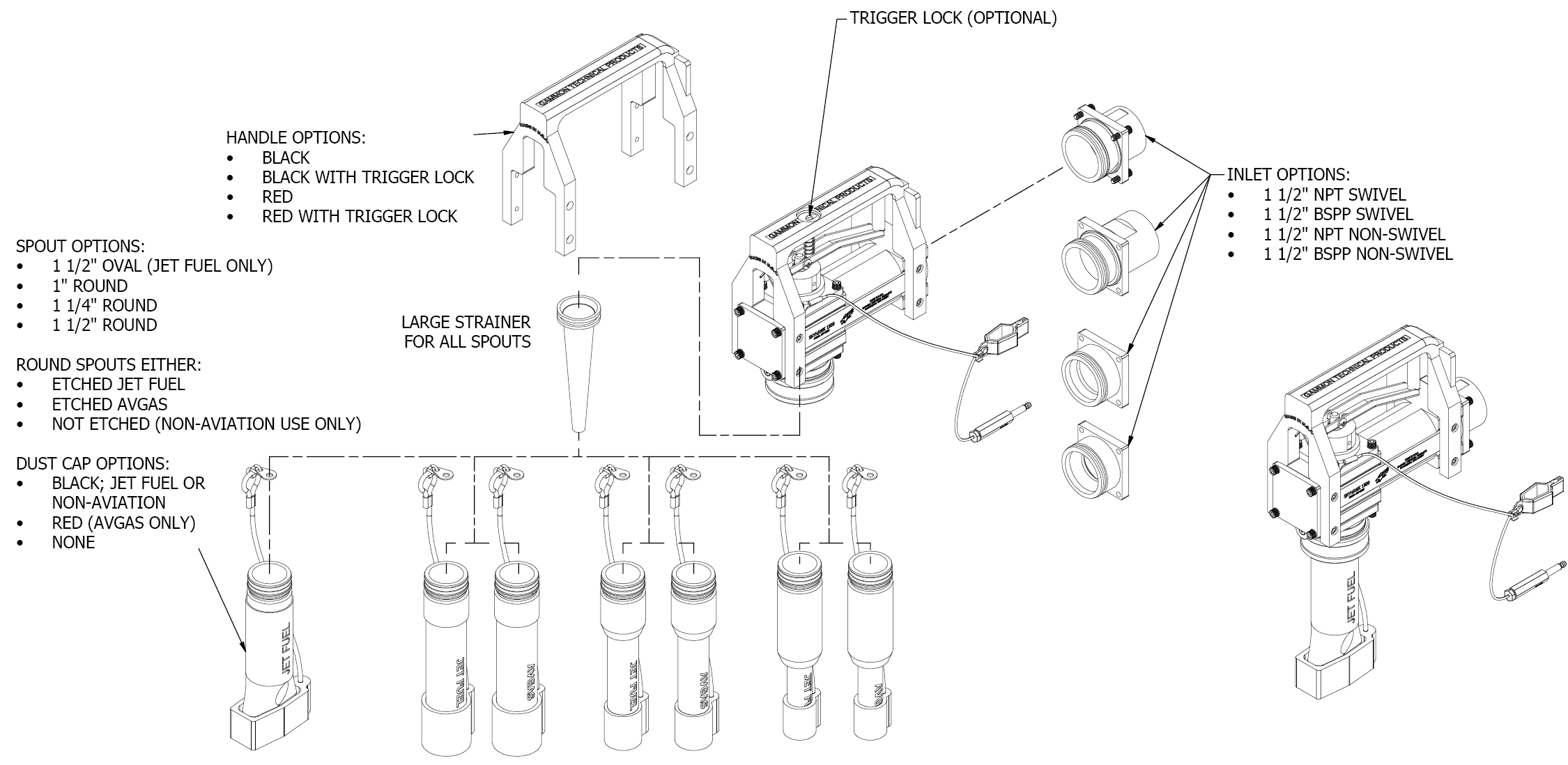

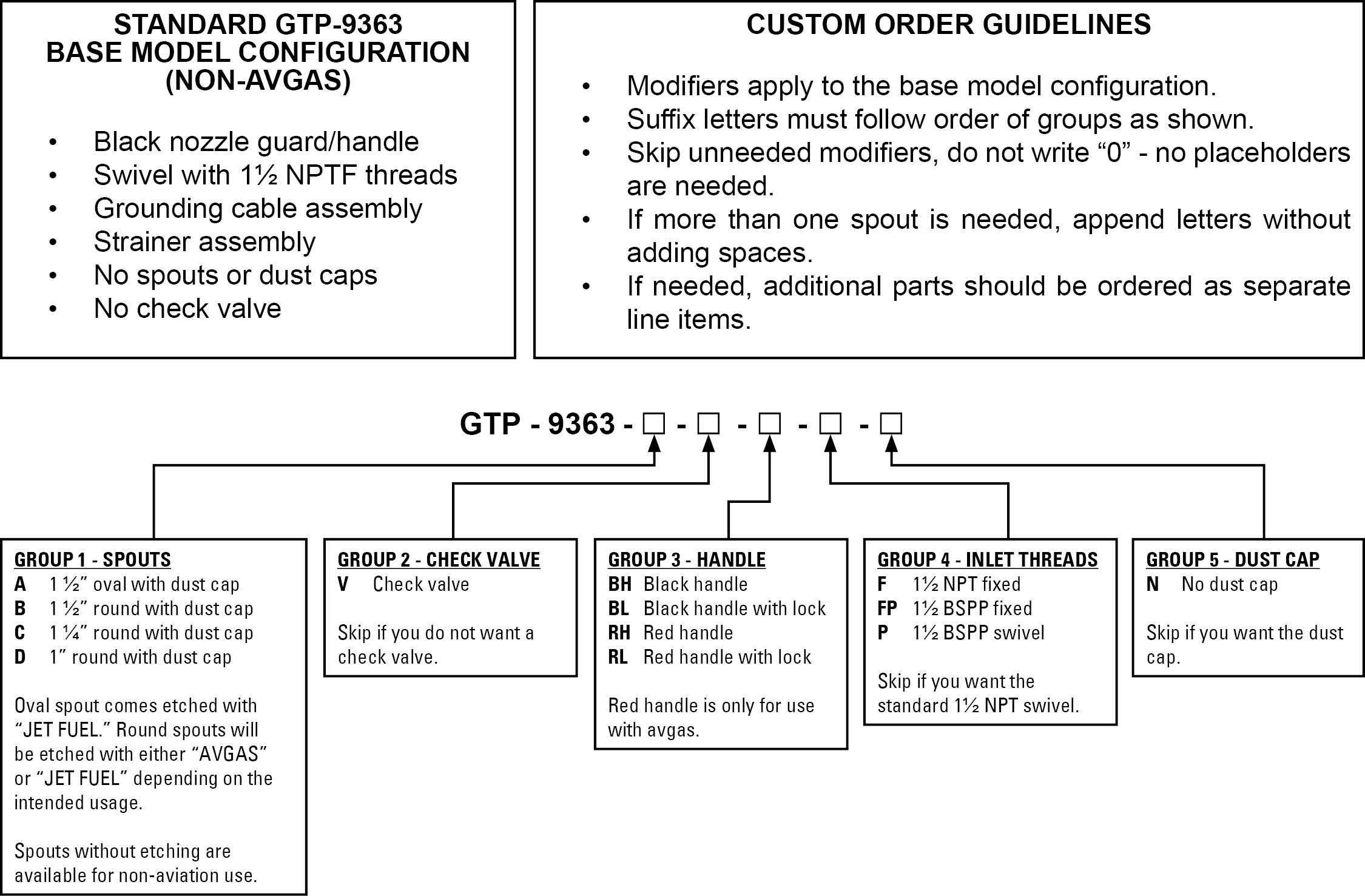

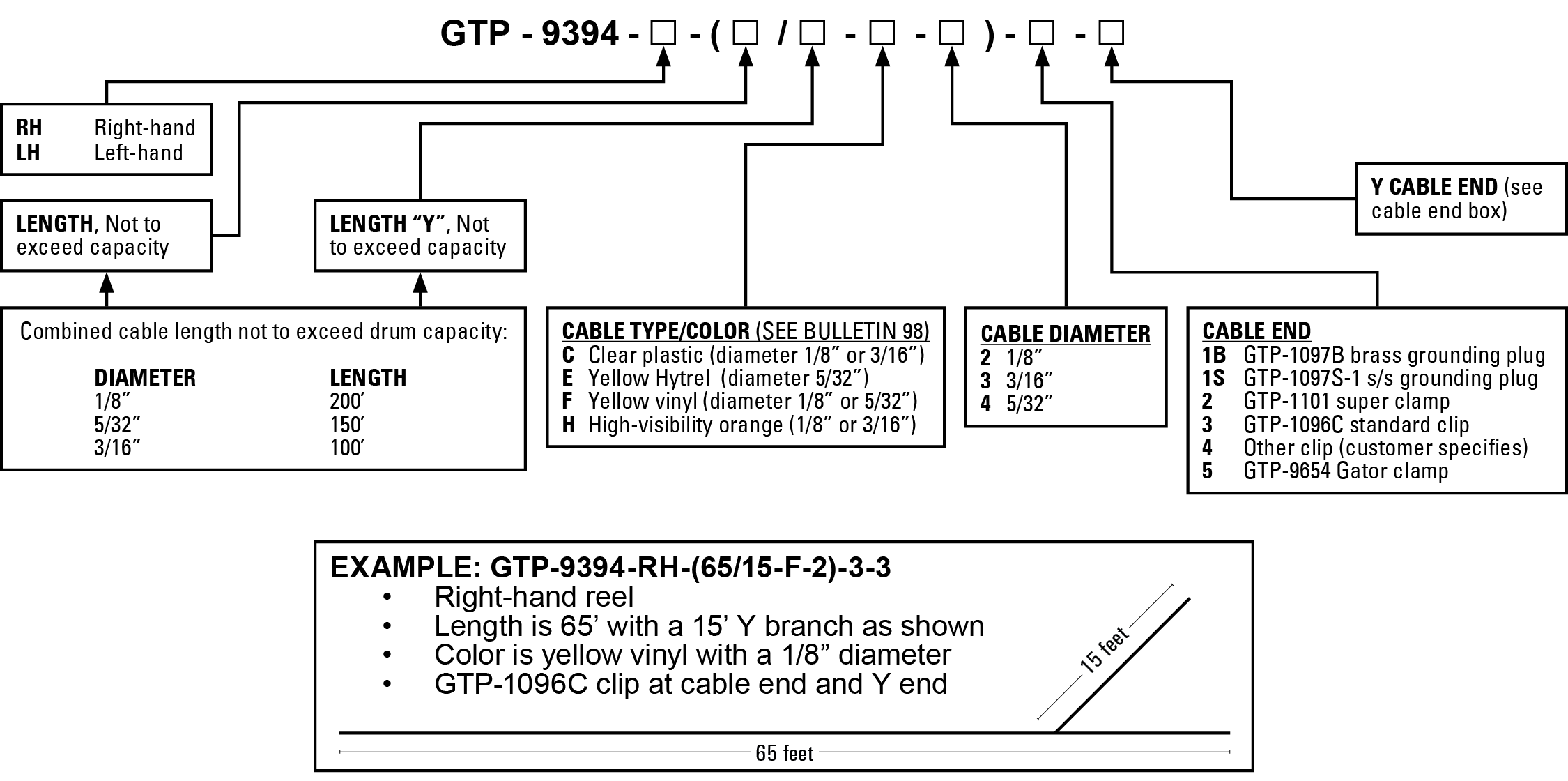

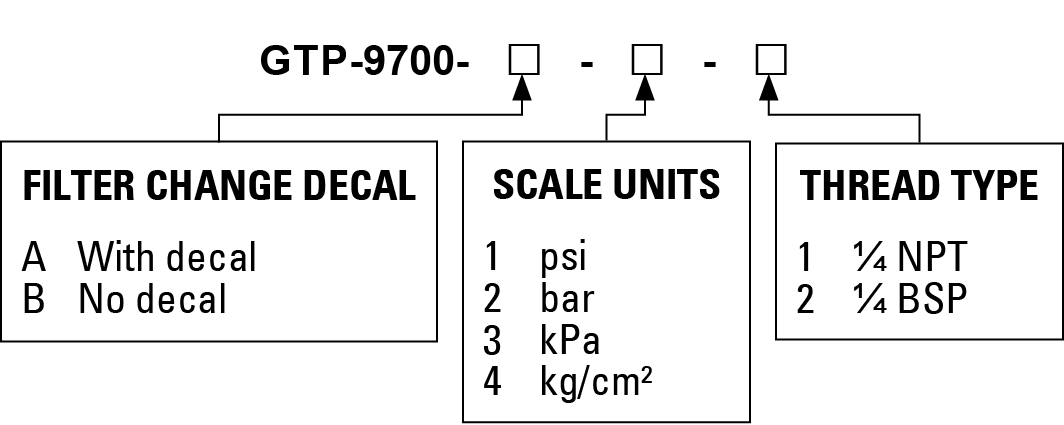

How to Order

Mini Gammon Gauge Control Systems

Protect Against Filter Element Bursting

Add a Differential Pressure Switch to the Gammon Gauge

Sound Alarm – Stop Flow – Turn on Second Filter

Normally Open or Normally Closed, Fail Safe

If differential pressure suddenly increases or a facility is operated without personnel monitoring the differential pressure, filter element failure can occur. This new switch is unique. It adds differential pressure control at a low cost using a non-powered proximity switch. This simple double-sealed switch is ideal for use in PLC (miniature computer) and relay controlled systems. The connection box is rated NEMA4X.

Control operations are also available if you don’t plan to use an external control. We have weather-tight and explosion-proof versions.

We strongly recommend a three-way test valve for properly testing the Mini Gammon Gauge and Proximity Switch and/or system.

Any Mini Gammon Gauge can be converted to include the new proximity switch.

Note: To meet IATA JIG Bulletin 58, order the “BKS” option for key switch reset and test functions. The ATA-103 does not require this. For vehicle mounting, we recommend the weather-tight housing.

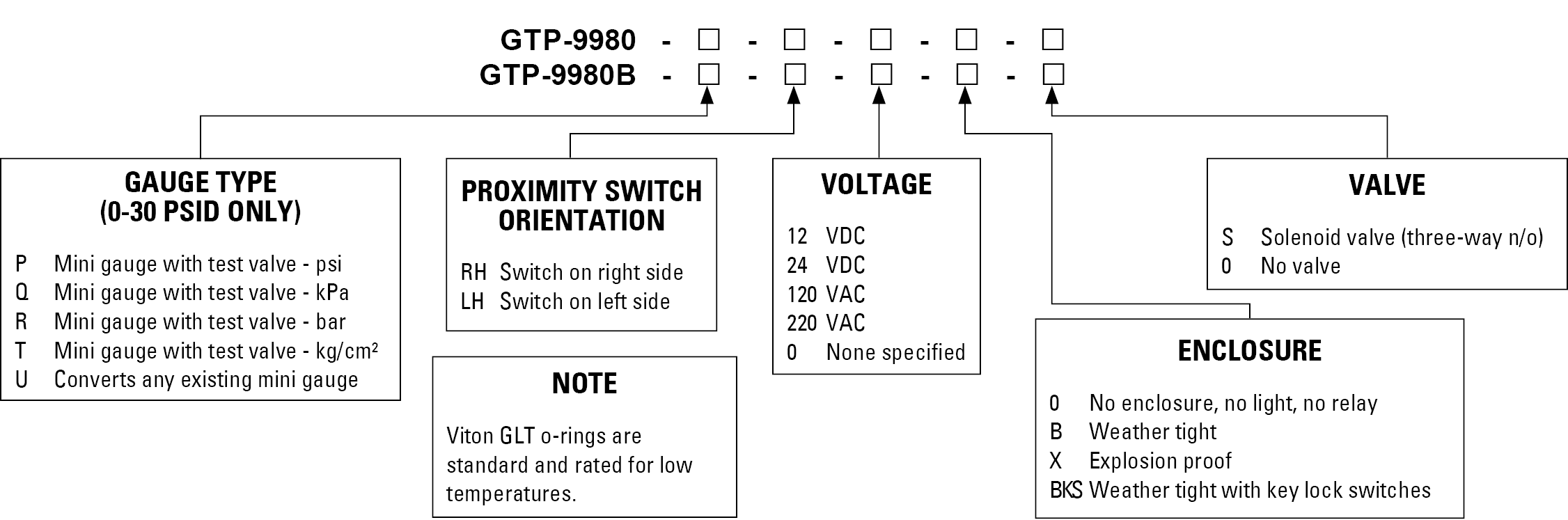

How to Order

Example:

GTP-9980B-P-RH-12-B-0 is a differential pressure gauge with a normally closed switch as follows: mini gauge with test valve, 30psi scale, switch on right side, 12 VDC, enclosure is weather tight which includes light and push to test feature, no solenoid valve, and low temperature o-rings.

GTP-9980B-P-RH-12-BKS-0 is the same as above except the enclosure has two key lock switches for test and reset as per IATA JIG Bulletin 58.

Notes:

- GTP-9980 has a normally open switch. The switch closes upon high differential pressure. If the cable to the controller is cut, high differential would never be detected.

- GTP-9980B has a normally closed switch. The switch opens upon high differential pressure. If the cable to the controller is cut, the system would go into alarm notifying the operator that something is wrong with the system.

- If a system is purchased without the controller (no enclosure), both types of switches are still available. When a complete system is ordered with an enclosure, it is our policy to provide a GTP-9980B fail safe system unless otherwise requested. The difference is in the internal wiring and components in the controller.