NOTE: For customers who prefer non-mercury thermohydrometers, add a suffix “B” to the part number for any of our API Gravity or Metric Density instruments listed below. Safe and easy, non-hazardous clean-up in case of breakage.

API Gravity Hydrometers and Thermometers

GTP-915GB is shown. Other models may vary in appearance.

| API Gravity Range | Thermometer Range | Divisions | Length (mm) | ASTM No. | GTP No. |

|---|---|---|---|---|---|

| 29-41 | 0-150° F | 2° | 380 | S554HL | GTP-1680GB |

| 37-49 | 0-150° F | 2° | 405 | S561HL | GTP-9155GB |

| 39-51 | no thermometer | 2° | 335 | 5H | GTP-1676 |

| 39-51 | 0-150° F | 2° | 330 | S555HL | GTP-915GB |

| 49-61 | 0-150° F | 2° | 380 | S556HL | GTP-1681G |

| 59-71 | 0-150° F | 2° | 380 | S557HL | GTP-1682GB |

| 64-76 | 0-150° F | 2° | 405 | S568HL | GTP-9185GB |

| 69-81 | 0-150° F | 2° | 380 | S558HL | GTP-1683GB |

Metric Density

The symbols on the left side of the charts below may help you to select the hydrometers you should order. Hydrometers and thermohydrometers marked with these symbols have special ranges that avoid the need to purchase two instruments to cover the range for aviation fuels. ASTM has assigned special numbers and has officially approved them. For example, most jet fuels have an API gravity range that requires ASTM S555HL but there are some fuels that need ASTM S554HL to reach 37° API. So the new ASTM S561HL, with a range of 37-49°, covers all jet fuels. ASTM S562HL covers Avgas. Each symbol also indicates additional qualities as described below:

| ■ | For metric density, ASTM 321H covers the range from 775 to 825 kg/m³, avoiding the need to purchase two hydrometers, ASTM 314H & 315H. Likewise, for a thermohydrometer, ASTM 345H handles the range from 775 to 825 kg/m³ but its thermometer is graduated in 0.2°C increments. Unfortunately, the temperature range had to be limited to -10 to +40°C. |

| ● | For extremely hot climates, we offer instruments with a density range down to 760 kg/m³ but these do not carry official ASTM designations. Instead, they are marked as a combination of 314H/315H and 303HL/304HL. |

Metric Density Hydrometers

GTP-1857 is shown. Other models may vary in appearance.

| Metric Density Range | Length (mm) | ASTM No. | GTP No. | |

|---|---|---|---|---|

| 650/700 kg/m³ | 330 | 312H | GTP-1855 | |

| ★ | 700/750 kg/m³ | 330 | 313H | GTP-1856 |

| ★ | 750/800 kg/m³ | 330 | 314H | GTP-1857 |

| ● | 760/825 kg/m³ | 330 | 314H/315H | GTP-5904-1 |

| ■★ | 775/825 kg/m³ | 330 | 321H | GTP-5904 |

| ★ | 800/850 kg/m³ | 330 | 315H | GTP-1858 |

Metric Density Thermohydrometers

GTP-5909-1 is shown. Other models may vary in appearance.

| Metric Density Range | Thermometer Range | Divisions | Length (mm) | ASTM No. | GTP No. | |

|---|---|---|---|---|---|---|

| 700/750 kg/m³ | -20 to +65° C | 0.5° | 380 | 302HL | GTP-1876GB | |

| 750/800 kg/m³ | -20 to +65° C | 0.5° | 380 | 303HL | GTP-1877GB | |

| ● | 760/825 kg/m³ | -20 to +65° C | 0.5° | 380 | 303HL/304HL | GTP-5909-1GB |

| ● | 775/825 kg/m³ | -20 to +65° C | 0.5° | 380 | 303HL/304HL | GTP-5909GB |

| ■ | 775/825 kg/m³ | -10 to +40° C | 0.5° | 395 | 345H | GTP-5909-2 |

| 800/850 kg/m³ | -20 to +65° C | 0.5° | 380 | 304HL | GTP-1878GB | |

| 800/850 kg/m³ | -35 to +50° C | 0.5° | 380 | – | GTP-1878-1GB |

Closed Circuit Sampler Hydrometers and Thermometers

These hydrometers are thermometers have been shortened so they will fit in Aljac JM-3001 samplers when the lid is closed. Graduated spacings remain the same as ASTM instruments but the ranges have been shortened in some cases.

GTP-3312-1GB is shown. Other models may vary in appearance.

| GTP-3312-1-GB | Thermometer, -20 to +60° C, graduated in 0.2° C increments (ASTM 136C), non-mercury |

| GTP-8708 | Hydrometer, API, 37 to 49, graduated in 2° F increments (no ASTM) |

| GTP-8709GB | Thermometer, -5 to +140° F, graduated in 0.5° F increments (ASTM 136F), non-mercury |

Selecting Hydrometers for Your Fuel

| Fuel Type | API Gravity | Relative Density | Metric Density | Lbs per U.S. Gallon |

|---|---|---|---|---|

| Diesel/No. 2 Fuel Oil | 25 – 40 | 0.82 – 0.90 | 825 – 904 | 6.87 – 7.53 |

| Jet A – Jet A1 | 37 – 50 | 0.78 – 0.84 | 779 – 839 | 6.49 – 6.99 |

| JP-4 – Jet B | 43 – 64 | 0.72 – 0.81 | 724 – 810 | 6.03 – 6.75 |

| Avgas – Motor Gasoline | 64 – 76 | 0.68 – 0.72 | 682 – 724 | 5.68 – 6.03 |

ASTM Specification E-1/E-100 Compliance

Any of the hydrometers in this brochure may be furnished with a NIST Traceable Certificate of Calibration at extra cost, upon request. This certificate shows actual data at three test points as required by ASTM E-100 (for hydrometers) or the test points required by ASTM E-1 (for thermometers). Actual readings are resolved to 1/10 of the smallest scale division. The test methods and NIST standards that are used, as well as uncertainties of measurement and all other necessary data to maintain full traceability are provided.

This calibration is performed by an independent calibration laboratory which is accredited to the international standard ISO/IEC 17025. Copies of the laboratory’s ISO 17025 Accreditation are available upon request for your qualified vendor files. To order this certificate, add the suffix “C” to our GTP number. There is an additional charge for this service.

Aviation Fuel API Gravity Test Kit

GTP-8810GB

This Jet A & Avgas quality control tool kit includes:

- GTP-1073A High-density polyurethane hydrometer jar

- GTP-1682GB Non-mercury thermohydrometer ASTM S557HL

- GTP-1683GB Non-mercury thermohydrometer ASTM S558HL

- GTP-915GB Non-mercury thermohydrometer ASTM S555HL

- GTP-3012-1A Conversion calculator

- Flash drive containing GTP catalog and GamGrams

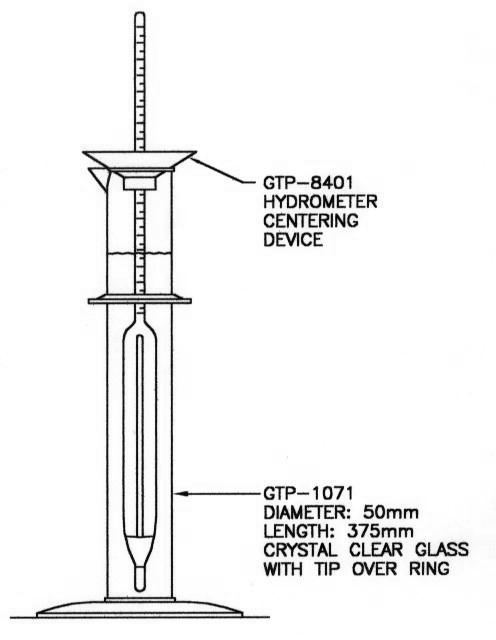

Colrud Hydrometer Centering Device

GTP-8401

This accessory eliminates errors caused by the hydrometer adhering to the side of the hydrometer jar. Loosely self-centering, this device dramatically reduces the time needed to obtain accurate readings, especially in outdoor conditions and for inexperience personnel. Developed with Dave Colrud, an Alaskan fuel Q.C. expert for use in all conditions. Tested by a top laboratory to confirm that it causes no error. Precision machined, fuel resistant, high-density plastic.

ASTM Thermometers

Non-mercury, certified to ASTM E-1 Specifications

| Range | Divisions | Length (mm) | ASTM No. | GTP No. | |

|---|---|---|---|---|---|

| For tank level gauging: | -30 to +120° F | 1° F | 300 | S58F | GTP-1670GB |

| For density or gravity: | -20 to +102° C | 0.2° | 420 | S12C | GTP-3312GB |

Thermometer Holder

With cup and lid, equipped with metal backing to dissipate static charges through wire cable. Cable not supplied; order separately, specifying length. Lid of cup is hinged to open as it is lowered into fuel.

| GTP-2126GB | holder with ASTM thermometer 58F |

Rejoining Mercury and Oil Separations in Thermometers

PLEASE UNDERSTAND: A separation of mercury in your thermometer is not a defect! It is a condition, normally caused by shock in transit, which of course must be rectified before using the thermometer, or you will experience significant errors in your readings.

There are two methods that you can use. The best way is by cooling. The more difficult way is by using heat. The object of both methods is to get the broken pieces of mercury into a chamber where they can rejoin. The bulb at the bottom is large enough to hold all of the mercury in the capillary when it is cooled in dry ice. If there are pieces of mercury left in the capillary after cooling, carefully tap it vertically on a padded surface. Allow the thermometer to warm naturally (do not heat it) in a vertical position, and observe the mercury column as it ascends into the capillary to be certain it is intact.

If dry ice is not available, you must use heat. Thermometers and thermohydrometers that are offered by Gammon Technical are made with an “expansion chamber” at the top of the capillary tube. The purpose of this chamber is to provide over-range protection in case the thermometer is heated beyond its scale range. This chamber may be used to rejoin separations provided that the amount of separated mercury is very small (not more than a few scale divisions in length). The thermometer should be heated in water that is warmed only slightly higher than its maximum reading. The objective is to apply only enough heat to urge the broken pieces of mercury into the expansion chamber, followed by a small portion of the main (intact) column. DO NOT USE FLAME! Great care must be taken to not fill the expansion chamber more than halfway, because the developed pressure can break the glass. Remove the thermometer from the heat, maintain it in a vertical position, and observe the mercury column as it retreats into the capillary to be sure it is intact.