Viper Additive Injection Systems

For most any additive in any fuel

Viper Additive Injectors are designed to accurately and reliably inject a wide range of additives into a flowing stream of fuel or other hydro-carbon liquid. All fluid-wetted components are 300 series stainless steel. For maximum accuracy, temperature range, and durability, we have a wide range of custom rubber seals available.

Available with or without controls, these injectors can be directly controlled by the new advanced LC, TCS, and other meter computers for simplicity and record keeping. Made in USA.

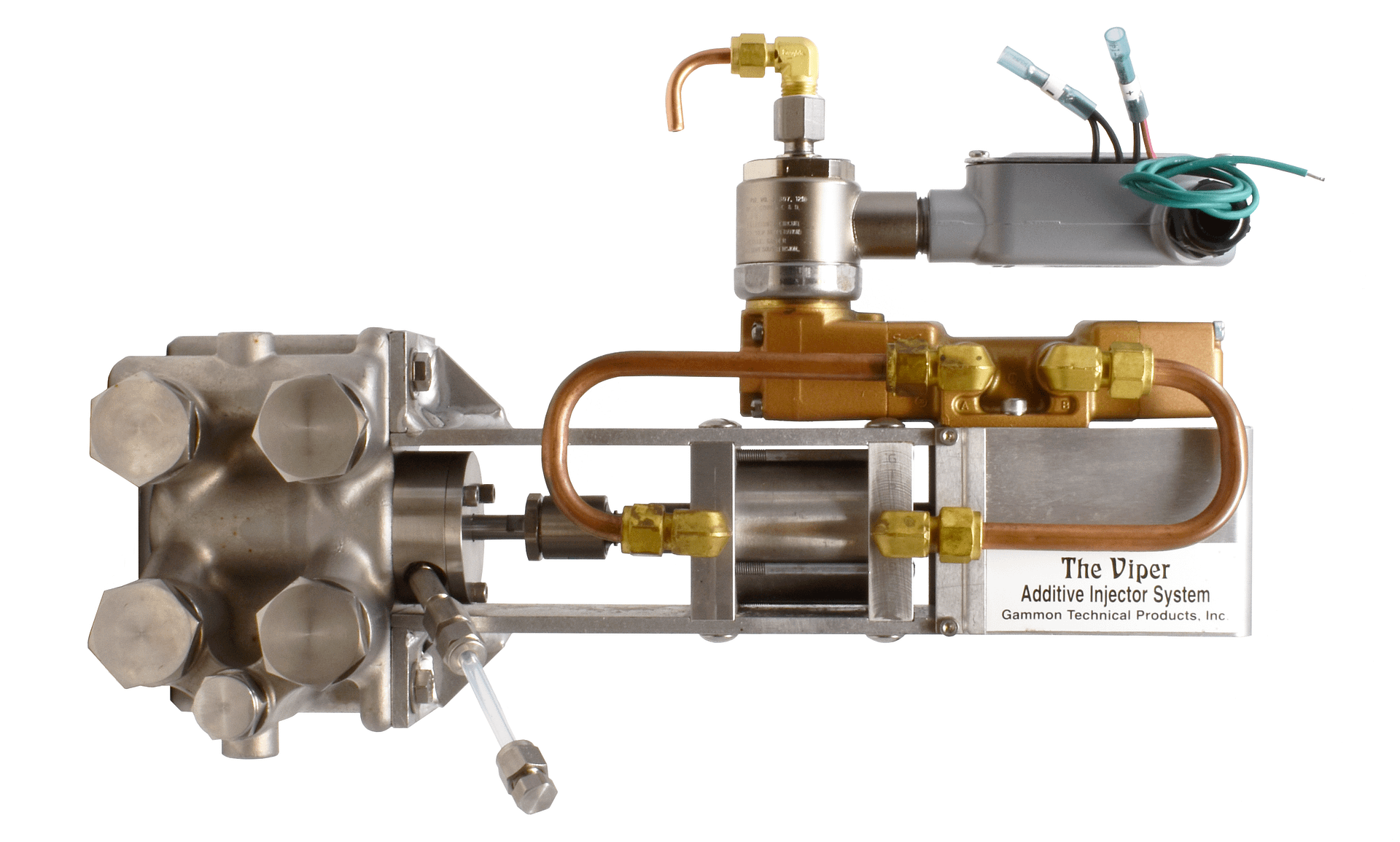

Viper Pump

The Viper pump is a simple concept. A double-acting, positive displacement, solid stainless steel piston pump, tested to provide a long life on clean additive before seal change of 30,000,000 gallons. All rubber (check valve) and PTFE (shaft and piston) seals, for reliability and accuracy. Self-cleaning check valve design, inlet strainer and main seal leakage detector. Compressed air powered, electronically controlled.

Our Heavy Duty mechanical adjuster is linear so if you change the adjuster 10%, the additive output changes 10%, unlike some competitors. Tested to -50° F. Viper pumps in service as long as 15 years have never needed adjustment, just occasionally new seals or a strainer cleaning. Checking is simple, flow volume into a test jar is the same as flow into the fuel stream.

Flow rates up to 1,200 gpm, additive rates up to 1,500 ppm. Includes a special test valve, high-visibility flow indicator, and atomizing injector nozzle.

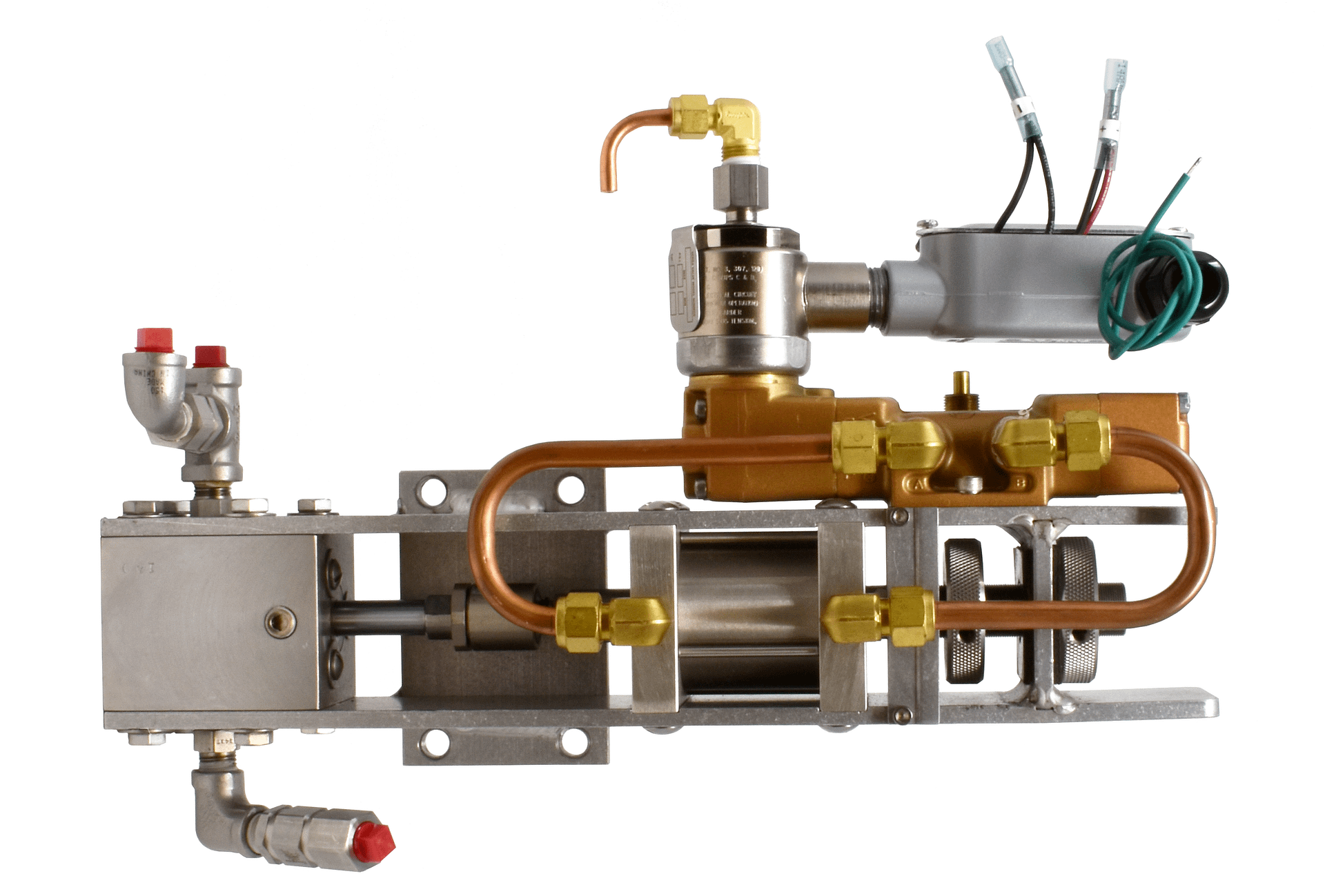

Viper Scorpion & Scorpion Mini

The Viper Scorpion is a smaller version of the Viper. Flow rates up to 500 gpm at 100 to 1,000 ppm. Compact and less expensive, but just as accurate and reliable.

The Viper Scorpion Mini is a simplified additive injection system without mechanical adjustment. Developed for use specifically with a meter computer such as the TCS or LC system. Additive meter required.

Viper Concord

The Viper Concord was developed long ago to inject CI/LI additive for the Concord SST. Designed to accurately inject additive at as low as 20 ppm at flow rates up to 1,000 gpm, the Concord was “brought out of retirement” to join the Viper line. Interestingly, the Concord has no Piston seal, utilizing a clean “return” design to prevent leakage.

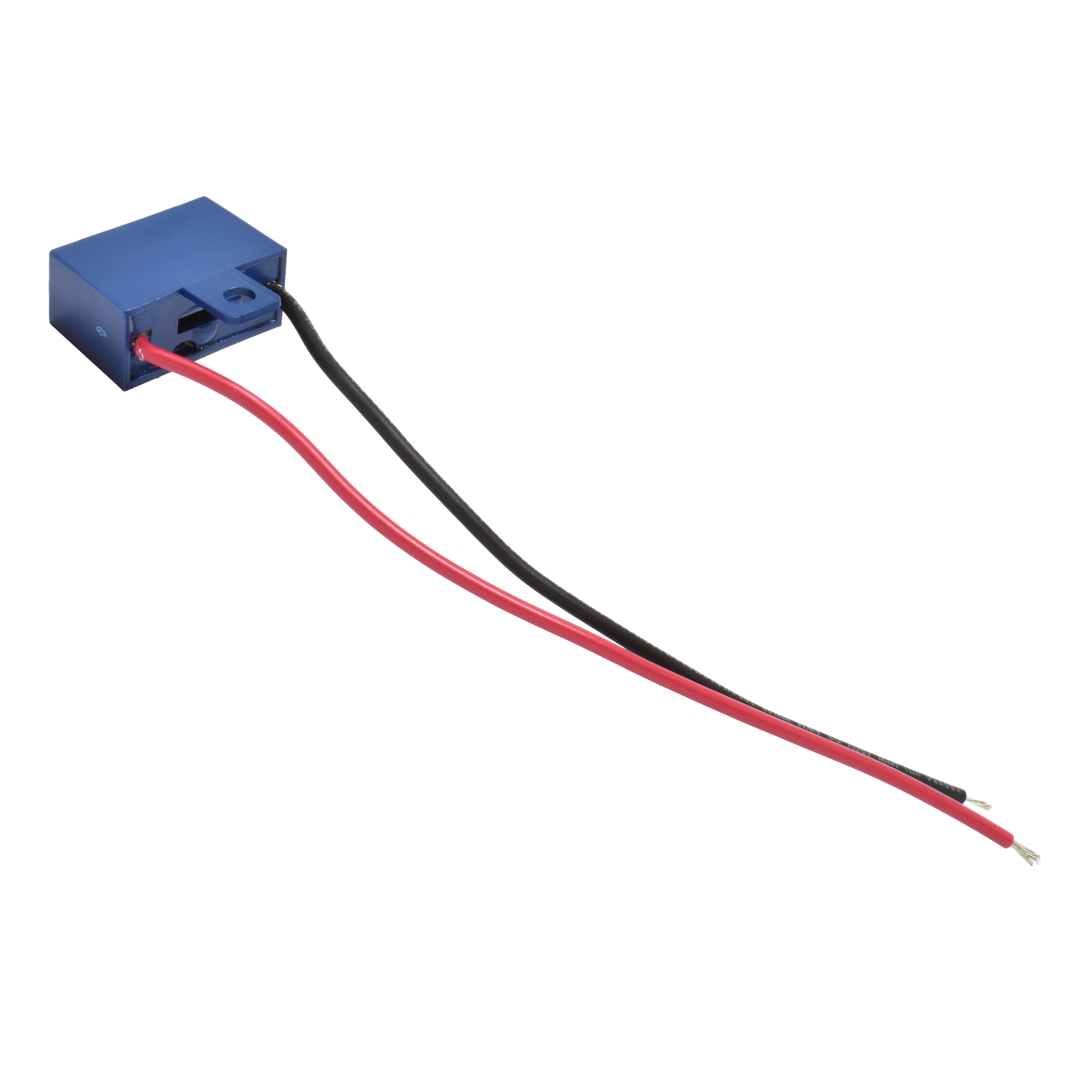

Digital Viper and Viper Eclipse Control System

The “brain” is a simple control, preset before shipment. No programming needed! The Digital Viper takes a pulse from your existing meter, and paces the additive flow rate to match the fuel flow. When interfaced with an on-board meter computer, can inject additive at different ratios for different customers, simply! A very simple system, using robust parts specifically built for this purpose.

The Viper Eclipse builds on the Digital Viper. It has a more advanced brain and a digital display. But don’t worry about programming, we do it all, no field programming needed. It has self-checking and self-adjusting ability, as well as a digital display with ppm, percent, gallons (or liters) of fuel and gallons (or liters) of additive displayed. It has warning and shutdown modes if additive concentration falls out of the set range. Includes additive meter calibration and priming modes. The Eclipse adds an additive meter and an intelligent “permissive” control system. The operator cannot dispense fuel without first telling the Viper Eclipse to inject, or not to inject additive. No more “forgetting” to turn the injector on or off. Maintaining a 1,000 operation memory of additive and fuel dispensed, date and time.

The Viper Eclipse Control System can be used with any of the Viper pumps.

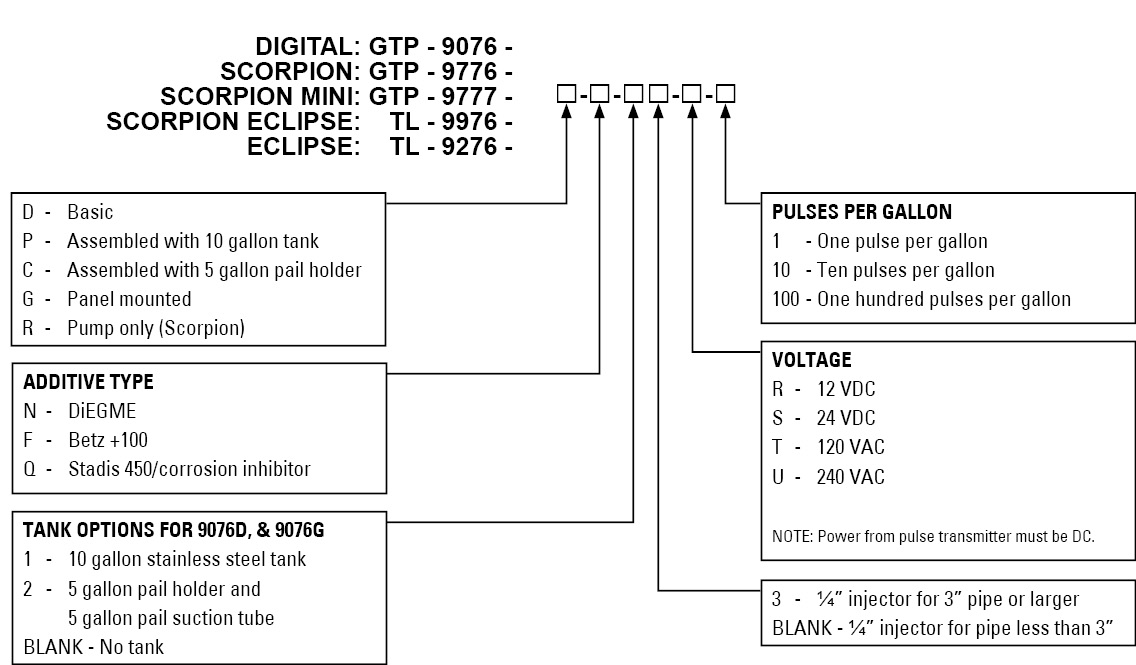

How to Order Vipers

NOTE: Not all combinations are possible.

How to Order the Viper Concord

Order the GTP-9076, with additive type Q (Stadis 450/corrosion inhibitor). Fill out all other boxes on the chart above as necessary for your application.

Parts & Accessories

NOTE: 55 gallon drums must be horizontal for best operation.

GTP-3355

55 gallon drum level indicator

GTP-3355-10

55 gallon drum rack

GTP-5504

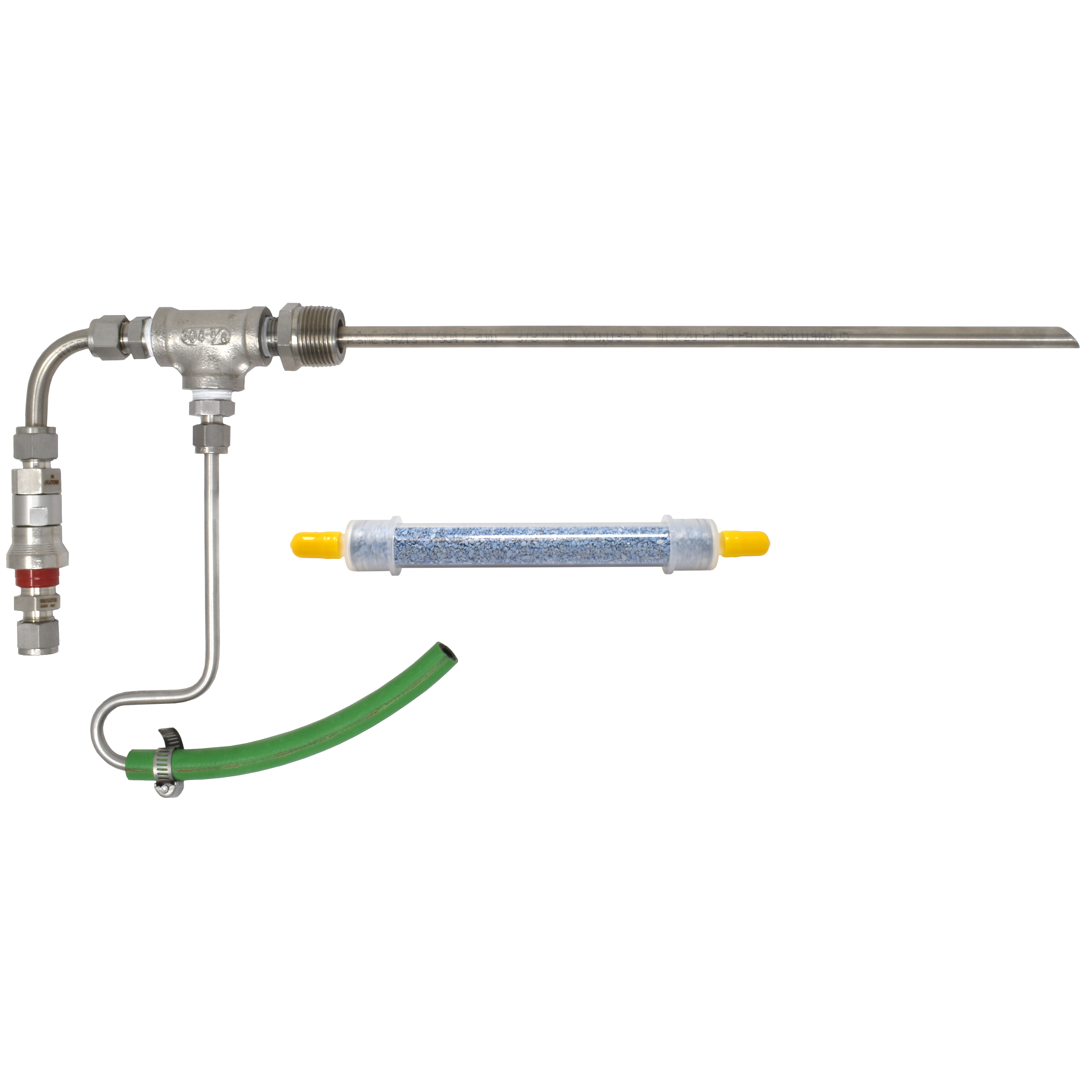

55 gallon drum suction tube

GTP-3895

55 gallon drum vent assembly

GTP-8807

injector (quill)

GTP-9651

air regulator/lubricator