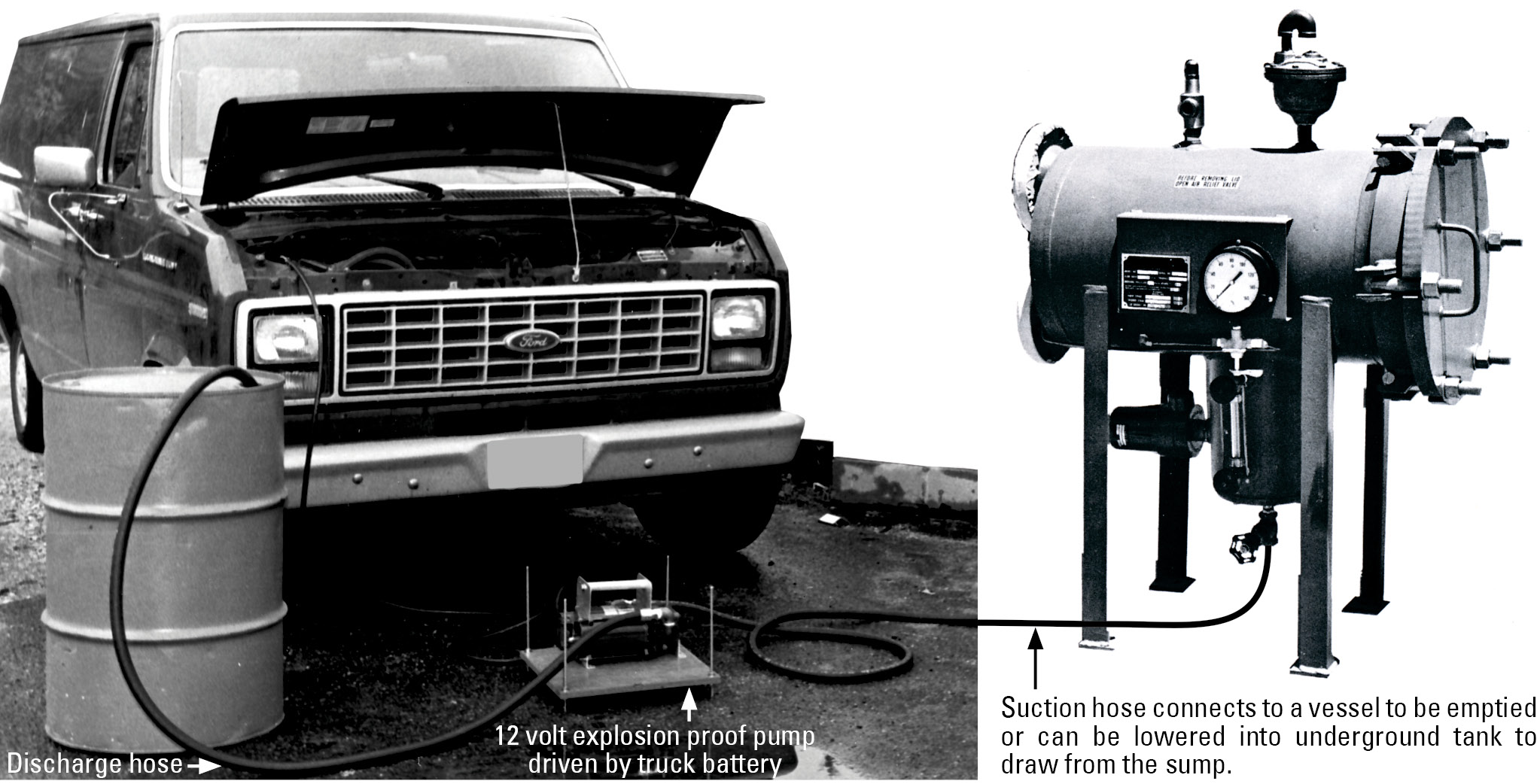

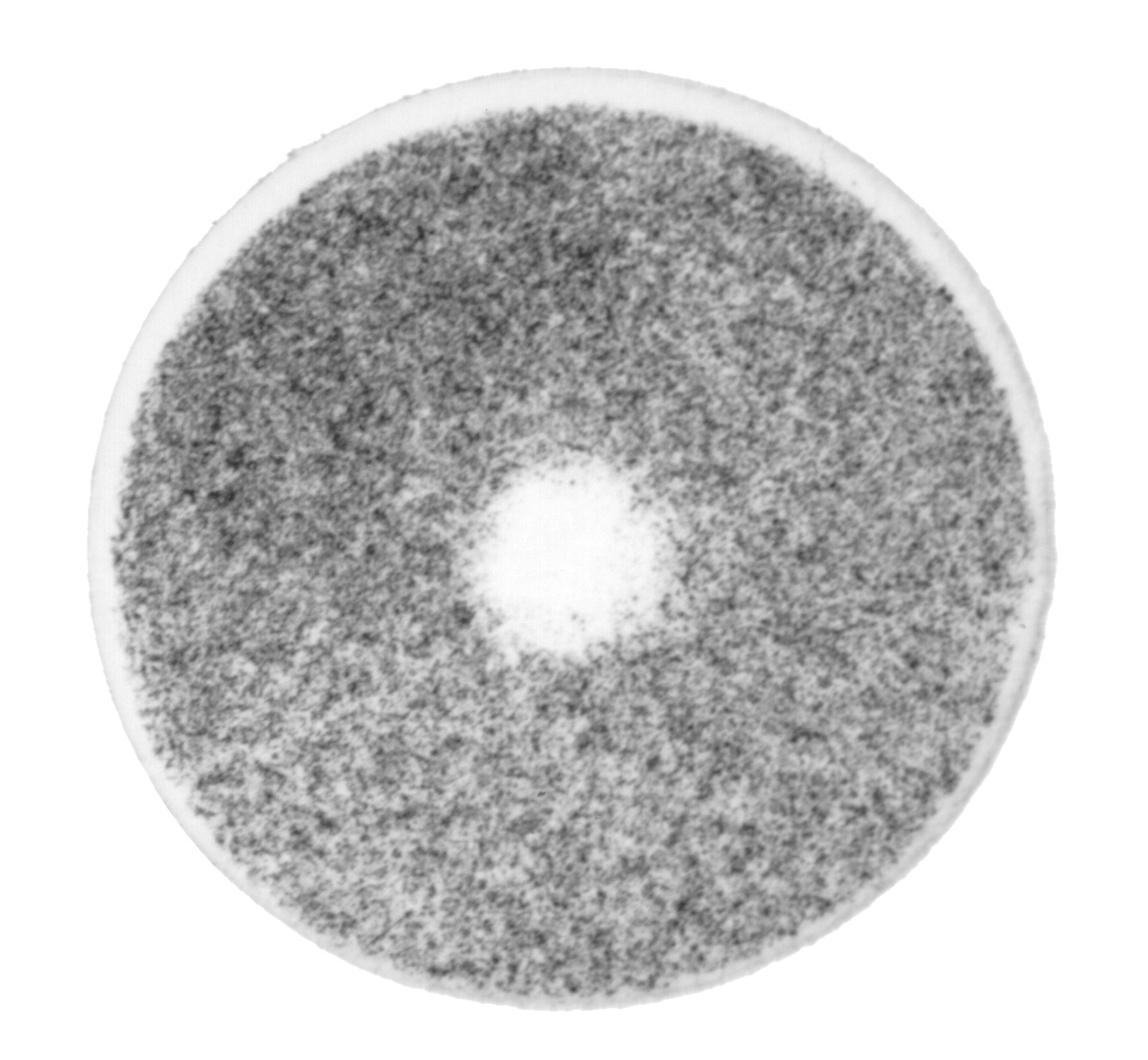

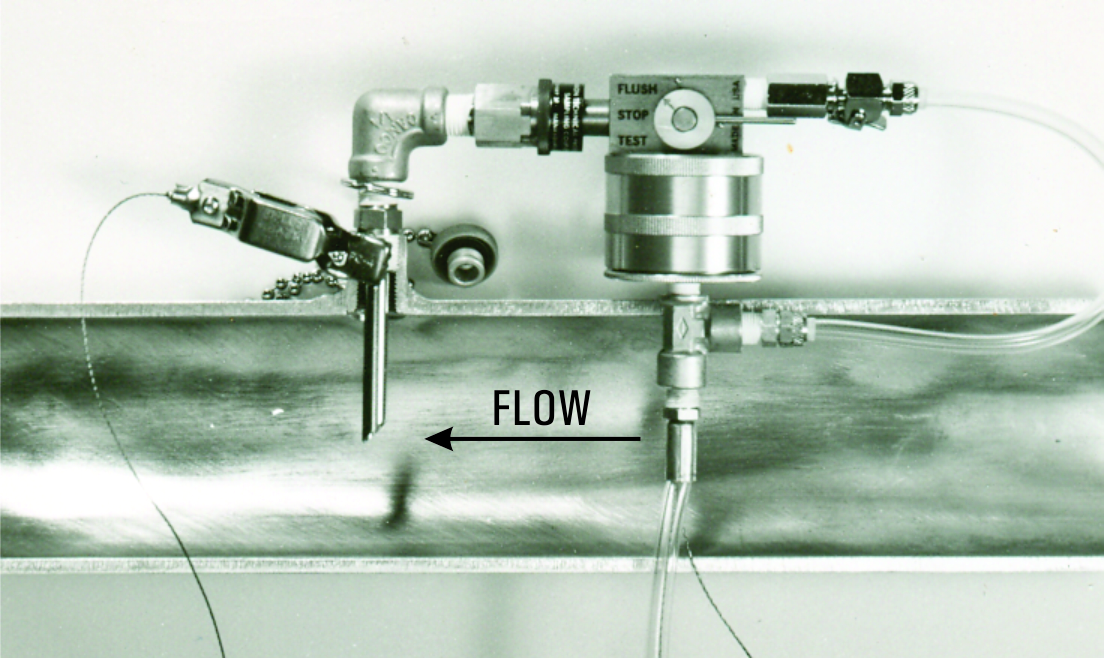

The Sump Separator separates water from fuel that is drained from storage tank sumps. The fuel and water mixture from the bottom of a storage tank or from the sump of a filter is discharged to the Sump Separator through a nozzle that causes a swirling action to concentrate most of the dirt in the center of the cone-shaped bottom. Water and fuel are allowed to separate by gravity.

The Gammon Sump Separator:

- Prevents fuel contamination of ground water.

- Allows for pollution control of soil and streams.

- Saves valuable fuel.

- Requires minimal maintenance.

- Eliminates the need for conventional waste or “slop” tanks.

- Features an internal epoxy white coating (stainless steel available on request).

- Has a capacity of 50 gallons standard & up to 300 gallons on special order.

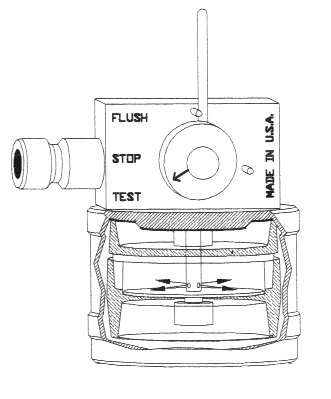

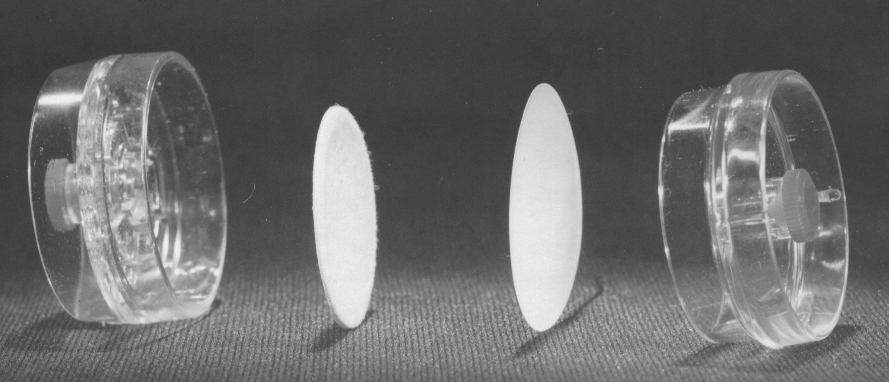

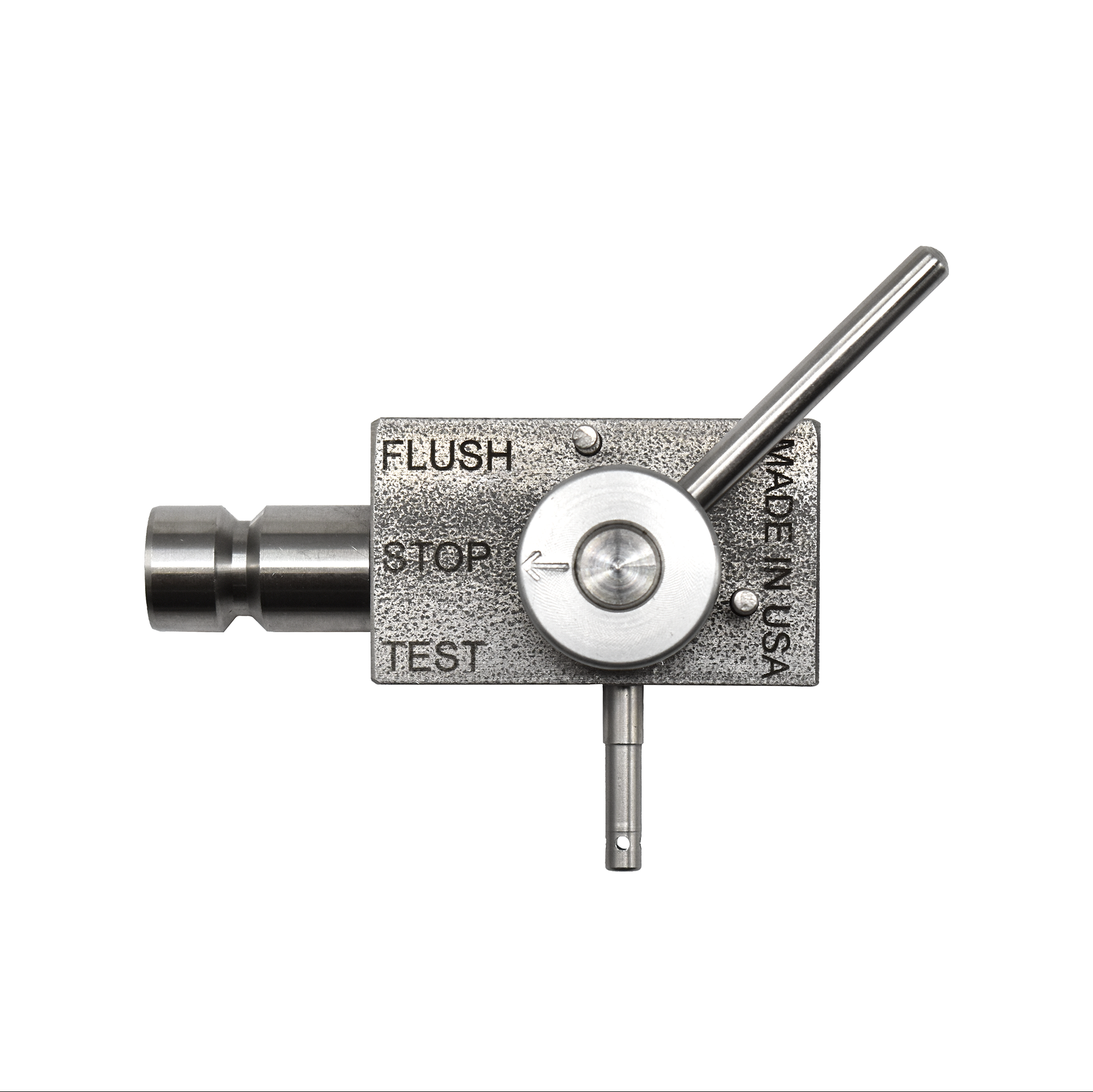

CLEAN CUT

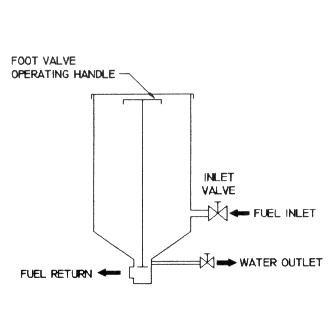

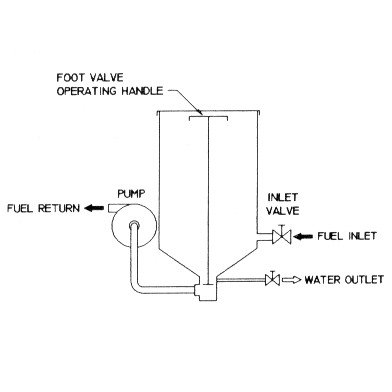

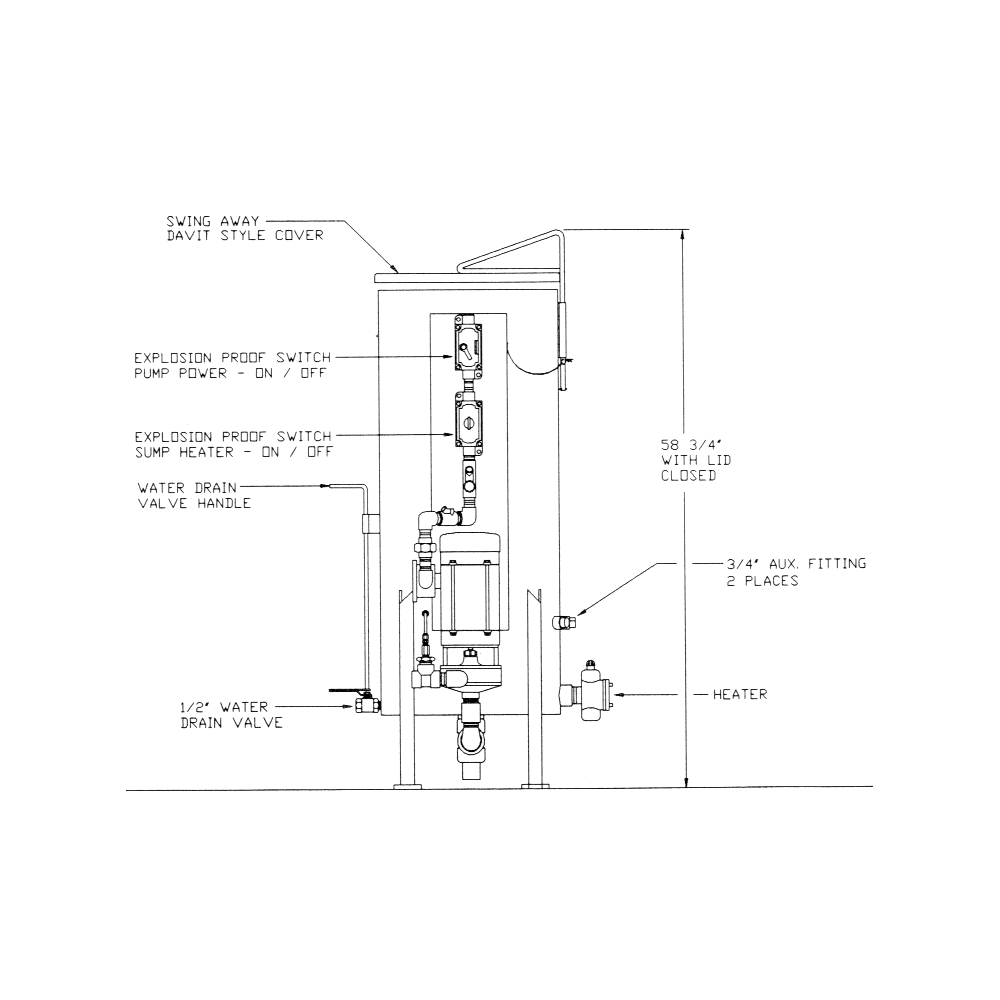

Only the Gammon Sump Separator makes possible a clean cut. The operator can easily see when the fuel/water interface has reached the bottom of the cone. When closing the water drain valve, the operator makes a clean cut, preventing any fuel from leaving with the water. Only fuel remains at the bottom of the cone.

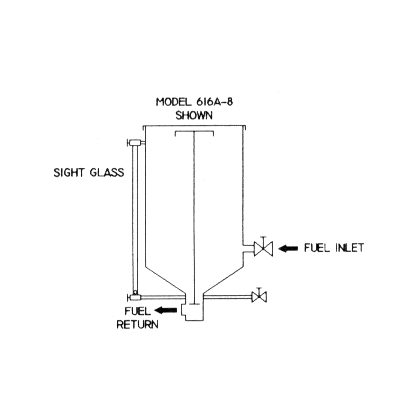

VISUAL CERTAINTY

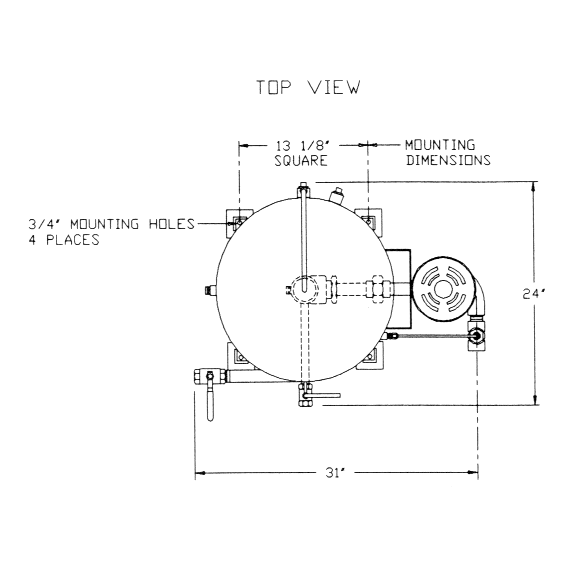

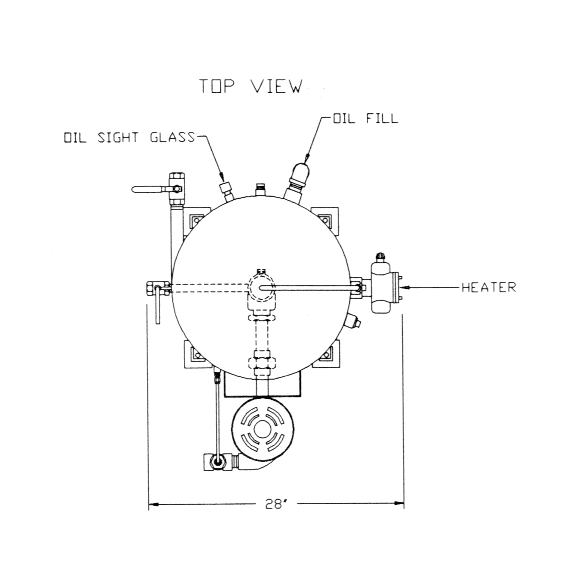

Direct visual observation of the fuel/water interface is achieved by swinging the cover on its davit so that the operator sees through the fuel to the interface. This provides visual certainty to make a clean cut.

Other sump separator designs on the market rely on a sight glass that the operator observes when draining off the water. Invariably, some of the fuel leaves with the water because the level in the sight glass always lags behind the level in the vessel. The operator can overcome this problem by closing the water drain valve ahead of time. The result is that some of the water is then pumped back to the storage tank.

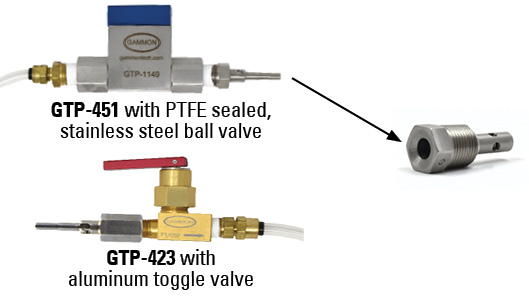

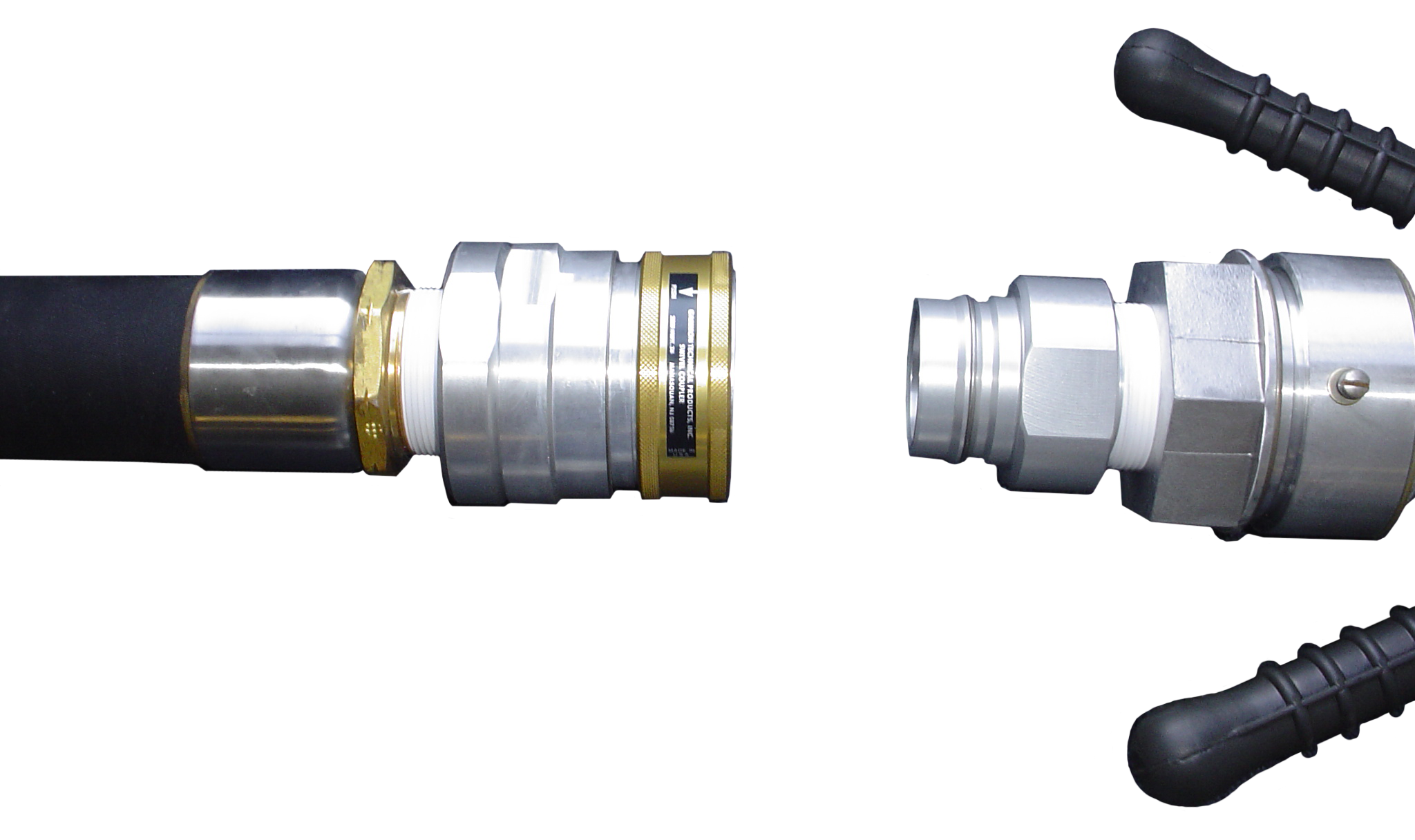

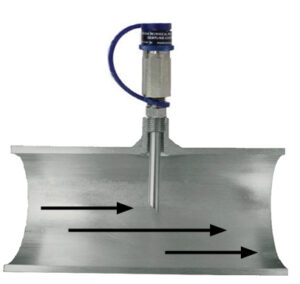

Gammon originated the sump separator in 1965 and has always used a stainless steel foot valve at the bottom of the cone as shown on page 2. All other manufacturers use common pipeline valves that cause some of the settled water to be pumped back to the storage tank.

No other manufacturer in the world can claim more than 50 years of experience in the sump separator business. In fact – we originated the name “sump separator”!

Not recommended for gasolines or other, low-flash point fuels.